PCB board FR4 material: Characteristics, Advantages and Application Guide

In the field of printed circuit board (PCB) manufacturing, the choice of substrate material is crucial. It directly affects the performance, reliability and production cost of the circuit board. Among them, FR4 material has become the most widely used substrate material in PCB manufacturing due to its comprehensive advantages. FR4 is a composite of epoxy resin and glass fiber cloth. This combination gives it excellent performance and plays a key role in many electronic devices.

Core characteristics of FR4

1. Electrical performance

FR4 material has stable insulation and good dielectric properties. This feature makes it suitable for most medium and low frequency circuits. When medium and low frequency circuits are running, FR4 can effectively isolate the current interference between lines and ensure stable signal transmission. However, it also has limitations. Due to the high loss of high frequency signals, FR4 is not suitable for ultra-high frequency application scenarios. Electronic equipment that processes ultra-high frequency signals, such as 5G communication base station core circuits and satellite communication equipment, need to choose materials that are more suitable for high frequency signal transmission.

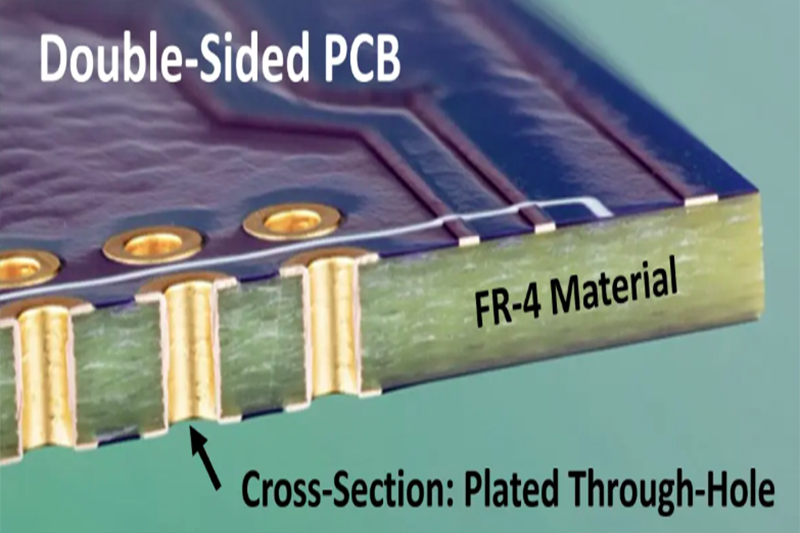

2. Mechanical properties

FR4 has high strength and rigidity due to glass fiber reinforcement. This makes it very suitable for rigid board design. Whether it is an electronic device used in daily life or a complex and harsh industrial environment, FR4 sheet can maintain a good physical form and is not easy to deform, thus ensuring the normal operation of components on the circuit board. In addition, FR4 provides a variety of thickness options. These diverse specifications can meet the needs of different electronic devices for multi-layer board stacking. From simple two-layer boards to complex dozens of layers of boards, FR4 can provide stable physical support.

3. Thermal performance

Welding is a necessary process for the manufacture of electronic equipment. FR4 material has good high temperature resistance and can withstand the high temperature environment of lead-free welding. This provides a guarantee for the application of modern environmentally friendly welding processes. FR4 has a moderate thermal expansion coefficient. But in practical applications, specially pay attention to matching with the copper layer. If the thermal expansion coefficient does not match, stress will be generated between the FR4 substrate and the copper layer when the temperature changes, which may cause the circuit board to delaminate and crack, affecting the normal operation of the equipment.

4. Other characteristics

FR4 has a high flame retardant grade, which is crucial to the safety of electronic equipment. When electronic equipment has abnormally high temperatures or sparks due to failure, FR4 can effectively prevent the spread of fire and reduce the risk of fire. At the same time, FR4 meets environmental protection standards. Under the global trend of advocating green environmental protection, this feature makes it more competitive in the field of electronic manufacturing. In addition, FR4 has excellent processing performance and can be well adapted to common PCB manufacturing processes such as drilling and etching, which is convenient for manufacturers to produce and process.

Core advantages of FR4

1. Low cost

FR4 is more competitively priced than some high-frequency materials. This makes it an ideal choice for mass production. For cost-sensitive industries such as consumer electronics, the use of FR4 material can not only ensure product performance, but also control production costs and improve product market competitiveness. The demand for large-scale production further reduces the unit cost of FR4, forming a virtuous circle.

2. High reliability

FR4 has excellent chemical corrosion resistance. It can maintain good performance whether in a humid environment or in contact with common chemicals. This corrosion resistance ensures the stability of the circuit board for long-term use, making it suitable for various complex industrial environments. In industrial equipment in industries such as petrochemicals and metallurgy, FR4 circuit boards can operate stably for a long time, reducing the frequency and cost of equipment maintenance.

3. Flexible design

FR4 is compatible with a variety of PCB manufacturing processes, including advanced processes such as multilayer boards and HDI (high-density interconnection). This provides electronic engineers with a broad design space. They can flexibly choose the appropriate process according to product requirements to design powerful and compact circuit boards. Whether it is a small smart wearable device or a large server motherboard, FR4 can meet diverse design requirements.

Typical application scenarios of FR4

1. Consumer electronics

FR4 is widely used in the field of consumer electronics. As the core component of mobile phones, the mobile phone motherboard uses FR4 material to reduce costs while ensuring performance and realize the thin and light design of mobile phones. The control circuit boards of household appliances such as refrigerators and air conditioners use FR4 material to ensure long-term stable operation. In addition, LED drive circuits also often use FR4 material to provide stable power supply and signal control for LED lamps.

2. Industrial equipment

FR4 is equally important in industrial equipment. PLC controller is one of the core equipment of industrial automation. Its circuit board uses FR4 material, which can operate stably in complex industrial environments and realize precise control of industrial production processes. The motor drive board is responsible for converting electrical energy into mechanical energy to drive the motor. The application of FR4 material ensures its safety and reliability in high voltage and high current environments. Industrial sensors are used to detect industrial production parameters, and FR4 material circuit boards provide them with a stable signal processing and transmission platform.

3. Automotive electronics

In the field of automotive electronics, FR4 is mainly used in in-vehicle entertainment systems, body control modules (non-high-temperature core components), etc. In-vehicle entertainment systems need to process multiple signals such as audio and video, and FR4 circuit boards can meet their requirements for signal transmission stability and cost control. The body control module is responsible for controlling automotive electronic equipment such as lights and windows. The application of FR4 materials ensures its reliable operation in the complex electrical environment of the car.

FR4 materials have become the mainstream choice in the field of PCB manufacturing due to their unique characteristics, significant advantages and wide application scenarios. With the development of electronic technology, FR4 materials will play an important role in more fields, and will continue to innovate and improve to meet the growing demand for electronic equipment manufacturing.

- more+releated article

- 2025-05-14PCB board FR4 material: Characteristics, Advan

- 2025-05-14Dry-Type Transformer Overheating: Causes, Solu

- 2025-05-13How Dry-Type Transformers Reduce Operating Cos

- 2025-05-13What are the limitations of phenolic cotton cl

- 2025-05-12Dry-Type Transformers for High-Rise Buildings:

- 2025-05-12How does phenolic paper sheet perform in a hum

- 2025-05-10CWIEME Berlin, here we come!

- 2025-05-10How to Verify the Accuracy of Dry-Type Transfo

- 2025-05-09Causes of Dry-Type Transformer Aging and Maint

- 2025-05-09FR4 Insulation Materials: Electrical Performan