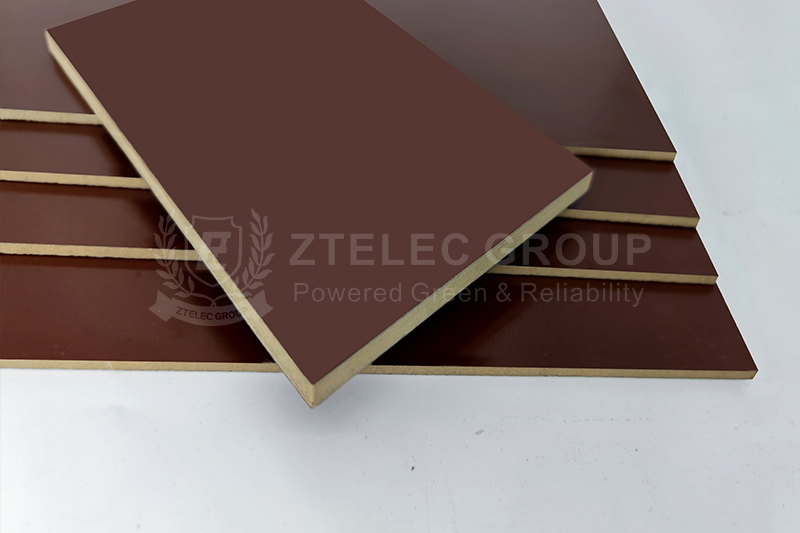

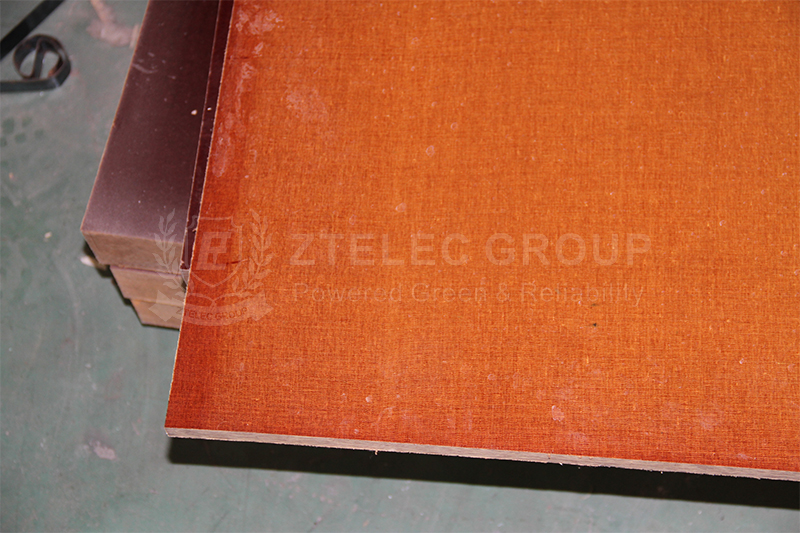

Phenolic Paper Sheet vs. Phenolic Cotton Cloth Sheet: Performance, Applications & Selection Tips

In today's rapidly developing industrial manufacturing and electrical insulation fields, phenolic laminates have become the core material choice for many industries due to their excellent mechanical properties, reliable electrical insulation properties and outstanding chemical corrosion resistance. Among them, phenolic paper sheet and phenolic cotton cloth sheets, as the two representative products of phenolic laminates, have their own unique performance advantages and play a key role in different application scenarios. This article will comprehensively analyze the performance differences and typical application areas of these two materials. At the same time, combined with actual application needs, it provides scientific and accurate selection recommendations to help purchasers and technical decision makers make the best material selection in project implementation.

Performance Differences between Phenolic Paper Sheet and Phenolic Cotton Cloth Sheet

Mechanical Properties

Due to the reinforcing effect of cotton fibers, phenolic cotton sheet exhibits strong mechanical strength and excellent heat resistance. It can maintain stable structural strength in high temperature environments and is suitable for scenarios with strict requirements on mechanical properties. In contrast, although the mechanical strength of phenolic paper sheet is not as good as that of phenolic cotton sheet, it still has sufficient performance to meet basic mechanical needs in general industrial applications.

Heat Resistance

In terms of heat resistance, phenolic cotton sheet performs outstandingly and can withstand high temperatures without significant performance degradation. It is an ideal choice for insulating materials for electrical equipment in high temperature environments. The heat resistance of phenolic paper sheet is relatively weak and is more suitable for use in relatively low temperature environments.

Corrosion Resistance and Water Absorption

Both have certain chemical corrosion resistance, but phenolic cotton sheet has the characteristics of strong water absorption. After absorbing water, its electrical insulation performance will be significantly reduced, and it is easy to breed mold in a hot and humid environment. Therefore, its application in hot and humid areas needs to be carefully considered. Phenolic paper sheet is relatively stable in terms of corrosion resistance and is less affected by environmental humidity.

Processing performance

From the processing perspective, both phenolic paper sheet and phenolic cotton cloth sheet have good processability and can be formed through a variety of processing methods such as sawing, drilling, turning, milling, and planing. Among them, phenolic cotton cloth sheet, due to its material properties, shows better plasticity and processing accuracy during processing, and has better processing performance.

Performance Differences between Phenolic Paper Sheet and Phenolic Cotton Cloth Sheet

Mechanical Properties

Due to the reinforcing effect of cotton fibers, phenolic cotton sheet exhibits strong mechanical strength and excellent heat resistance. It can maintain stable structural strength in high temperature environments and is suitable for scenarios with strict requirements on mechanical properties. In contrast, although the mechanical strength of phenolic paper sheet is not as good as that of phenolic cotton sheet, it still has sufficient performance to meet basic mechanical needs in general industrial applications.

Heat Resistance

In terms of heat resistance, phenolic cotton sheet performs outstandingly and can withstand high temperatures without significant performance degradation. It is an ideal choice for insulating materials for electrical equipment in high temperature environments. The heat resistance of phenolic paper sheet is relatively weak and is more suitable for use in relatively low temperature environments.

Corrosion Resistance and Water Absorption

Both have certain chemical corrosion resistance, but phenolic cotton sheet has the characteristics of strong water absorption. After absorbing water, its electrical insulation performance will be significantly reduced, and it is easy to breed mold in a hot and humid environment. Therefore, its application in hot and humid areas needs to be carefully considered. Phenolic paper sheet is relatively stable in terms of corrosion resistance and is less affected by environmental humidity.

Processing performance

From the processing perspective, both phenolic paper sheet and phenolic cotton cloth sheet have good processability and can be formed through a variety of processing methods such as sawing, drilling, turning, milling, and planing. Among them, phenolic cotton cloth sheet, due to its material properties, shows better plasticity and processing accuracy during processing, and has better processing performance.

Differences in application scenarios between phenolic paper sheet and phenolic cotton cloth sheet

Application fields of phenolic paper sheet

Low-voltage electrical insulation field: In low-voltage electrical equipment, phenolic paper sheet is often used to make insulating parts such as knife switch bases and wiring baffles of distribution boxes. With its stable electrical insulation performance and moderate mechanical strength, it provides reliable protection for the safe operation of low-voltage electrical appliances.

Insulating parts of the electronics industry: In the electronics industry, phenolic paper sheet is widely used in insulating gaskets, partitions and other parts of printed circuit boards (PCBs), effectively isolating circuits, preventing short circuits, and ensuring the stable operation of electronic equipment.

Insulating structures of other electrical equipment: In addition, phenolic paper sheet also plays an important role in the insulation structure of electrical equipment such as transformers and motors, meeting the dual needs of equipment for electrical insulation and basic mechanical strength.

Application scenarios of phenolic cotton cloth sheet

Insulation of mechanical and motor equipment: With its excellent mechanical properties and heat resistance, phenolic cotton cloth sheet has become a common material for insulating structural parts of mechanical and motor equipment, such as washers, slot wedges, screws, etc., providing solid insulation support for the efficient operation of equipment.

Electrical equipment in high-temperature environments: In electrical equipment working in high-temperature environments such as high-temperature ovens and electric furnaces, phenolic cotton cloth sheets can maintain good insulation performance under high-temperature conditions due to their excellent heat resistance, ensuring safe and stable operation of the equipment.

Flexibility demand scenarios: For electrical equipment insulation parts that need to be bent or deformed frequently, the flexibility advantage of phenolic cotton cloth sheets can be fully utilized, which can adapt to complex working environments and ensure the normal operation of equipment.

How to choose phenolic sheet?

In actual projects, choosing between phenolic paper sheet and phenolic cotton cloth sheet requires comprehensive consideration of multiple key factors:

Electrical performance requirements

If the project has extremely high requirements for electrical insulation performance, and the use environment is dry and the temperature is low, phenolic paper sheet can meet the requirements with its stable electrical insulation performance, while having a high cost performance ratio. In humid or the high temperature environment, although the water absorption of phenolic cotton cloth sheet will affect the electrical insulation, it can still show good electrical performance adaptability in complex electrical environments through reasonable protective measures.

Mechanical performance requirements

When the project has high requirements for mechanical strength, flexibility and impact strength, phenolic cotton cloth sheet becomes the best choice due to its excellent mechanical properties. For projects with relatively low mechanical performance requirements and more emphasis on electrical insulation performance and cost control, phenolic paper sheet is a more suitable choice.

Heat resistance requirements

If the use environment temperature is high, the excellent heat resistance of phenolic cotton cloth sheet can ensure that the material works stably at high temperatures and ensure equipment safety. In an environment with relatively low temperature, phenolic paper sheet can meet the basic heat resistance requirements, and there is no need to invest higher costs to choose phenolic cotton cloth sheet.

Chemical corrosion resistance performance requirements

In an environment where there is a risk of chemical corrosion, phenolic paper sheet can effectively resist chemical erosion and extend the service life of the equipment with its better chemical corrosion resistance. If the risk of chemical corrosion is low, phenolic paper sheet or phenolic cotton cloth sheet can be flexibly selected according to the project's emphasis on other performance.

Cost factors

Phenolic paper sheet is usually low in cost due to its relatively simple raw materials and production process, and is suitable for cost-sensitive projects. Phenolic cotton cloth sheet has a relatively high production cost due to the addition of cotton cloth fiber as a reinforcing material, but its excellent comprehensive performance also provides value guarantee for projects with higher requirements for material performance.

- more+releated article

- 2025-04-23Phenolic Paper Sheet vs. Phenolic Cotton Cloth

- 2025-04-23Revealing the Advantages of Dry-Type Rectifier

- 2025-04-22The Popularity of Dry-Type Transformers: Key R

- 2025-04-21FR5 vs. FR4 Epoxy Sheet: Which One Fits Your P

- 2025-04-21Dry-Type vs. Oil-Immersed Transformers: A Comp

- 2025-04-19Losses in Oil-Immersed Power Transformers: Mec

- 2025-04-19Why Choose FR5 Epoxy Sheet for High-Temperatur

- 2025-04-18Key points of oil-immersed transformer mainten

- 2025-04-18Lebanese Customers visit Zhongtian Electrical

- 2025-04-18The Features and Diverse Applications of FR5 E