What Is Halogen-free FR-4?

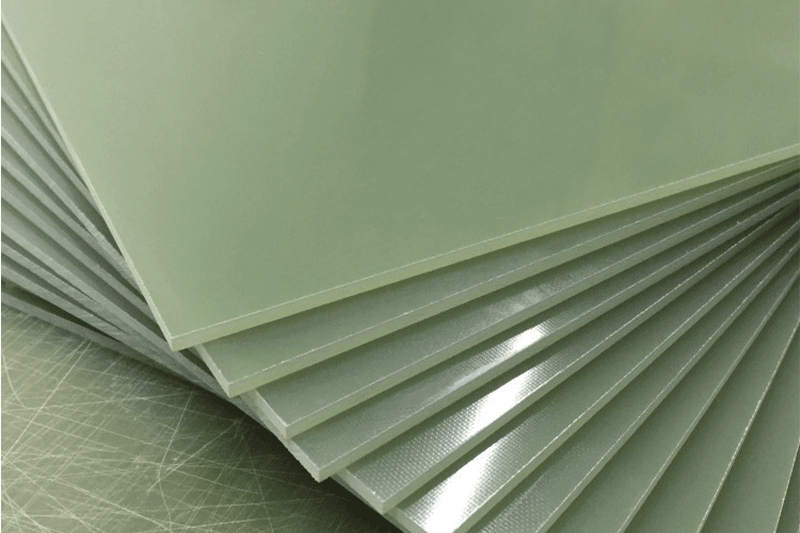

When it comes to “halogen”, people’s first reaction is the sweet-smelling flavoring bag used for braised meat. But today, what I want to explain is halogen-free FR-4, one of our featured products. It is an environmentally friendly epoxy fiberglass laminate with halogen-free flame retardant added.

The halogen elements on the periodic table of chemical elements include fluorine (F), chlorine (CL), bromine (Br), iodine (I) and astatine (At). They exist in nature as typical of salts. “FR” means flame retardant. “4” represents a category of reinforced sheet materials, i.e., the fiberglass substrata. Halogen-free FR-4 can simply be regarded as an improved non-halogen product reinforced with the properties of flame retardance.

Definition and Type of the Flame Retardant

The flame retardant (hereinafter abbreviated to FR), as a functional agent, makes it difficult for the combustible polymers to burn. It’s developed initially for flame retardation of polymer materials. According to usage, FR can be divided into the additive FR and the reactive FR. The former can be directly mixed with polymers to give them properties of slowing down combustion. Such type of FR generally includes organic FR and inorganic FR, halogenated FR and halogen-free FR. The latter, reactive FR, participates in polymerization reactions as a monomer so that the polymer itself contains FR components.

Difference Between Halogenated FR and Halogen-free FR

Halogenated FR is a halogen-containing polymer or a halogen-containing FR combination, the main ones being antimony trioxide (Sb2O3) and decabromodiphenyl oxide (abbreviated to DBDPO), i.e. the most commonly seen brominated FRs. They have low price, good stability and excellent compatibility with synthetic resin materials. However, studies have shown that materials made with halogenated FR, when heated and burnt, will release large amounts of highly toxic smog and gases which are comprised of dioxins (a very poisonous chemical used in industry and farming), benzofuran, etc. with an offensive odor. These gases are classified as carcinogenic substances by the World Health Organization. If inhaled in, they cannot be discharged from the living body, seriously detrimental to health. On Dec.5,2019, the European Union issued a regulation that halogenated FR are banned from being used in the casing and support of the electronic display. Halogen used as a raw material will bring great side effect, so it’s necessary to ban it.

By contrast, halogen-free flame retardant is a type of high-performance organic FR containing phosphorus and nitrogen, mainly including triazine triketone and triazine triamine compounds. Halogen-free FRs boast many advantages, not easy to be precipitated from the resin material after special treatment to its surface and have good flame retardant effect. Most importantly, there will be a small amount of smog when burning, and without toxic gas produced.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri