email us:

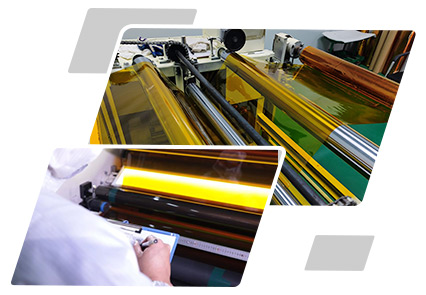

Polyimide film6050 is a synthetic resin composed of pyromellitic dianhydride and 4.4-diamino diphenyl ether. It is produced by the "salivation method", which has high-temperature resistance, radiation resistance, and excellent dielectric properties.

Economical, Reliable, HSigh temperature resistant synthetic resin coating

Polyimide Film 6050 is designed for high-temperature coating applications with a synthetic resin coating of pyromellitic dianhydride and 4.4-diamino diphenyl ether. It is ideal for high-temperature applications up to 500°F/260°C. Its light amber color ensures easy identification and alignment.

If you are considering purchasing this or other Zhongtian Group products, our team is always ready to provide you with more services and product designs. Our service, product quality, and professional technical support to customers allow us to help you gain more opportunities and challenges. In the future, we will do our best to prove that your choice is very correct, and we are the most suitable supplier for you.

We passed the lS09001 quality management system and ISO14001 environmental management system certification, UL certificates for the whole production, and SGS certificated product environmental testing. Our factory has the capacity of over 1000T/M on different rigid laminates, equipped with 4 labs for mechanical, chemical, electrical, and Electronics performance testing. We implement the concept of total quality management and hope to provide customers with perfect products and services.

ZTelec Group's (founded in 1958) main products include the full range of epoxy fiberglass sheets (FR4, FR5, G10, G11, etc.), F-H-grade heat-resistant materials, specially modified resin insulation materials (BMI, G7, Pl, etc) and high-precision processing parts, as well as Bakelite and ESD sheets and so on for electronic industries, cCL, and Machining factories.

Website:https://www.ztelecgroup.com