10kV Dry-Type Transformer 30–4000kVA | Cast Resin Structure Explained

In modern power systems, dry-type transformers have become a preferred solution for power distribution in commercial buildings, industrial facilities, and infrastructure projects due to their high safety level and operational reliability. Among them, the 10kV cast resin dry-type transformer with a capacity range of 30–4000kVA plays a critical role in medium-voltage distribution networks. Its advanced structural design and superior insulation performance make it an ideal choice for environments with strict safety and environmental requirements.

This article provides a detailed overview of product definition, manufacturing process, structural characteristics, insulation advantages, application scenarios, and key considerations for selection and installation, serving as a practical reference for engineers and project planners.

What Is a Cast Resin Dry-Type Transformer?

A cast resin dry-type transformer is a distribution transformer in which the high-voltage and low-voltage windings are encapsulated with epoxy resin under vacuum conditions. This process forms a dense, sealed, and mechanically robust insulation system around the coils.

Compared with traditional oil-immersed transformers, cast resin dry-type transformers offer clear advantages such as maintenance-free operation, elimination of fire hazards caused by oil leakage, and excellent environmental performance. The 10kV voltage class is well suited for medium-voltage distribution systems, while the 30–4000kVA capacity range supports applications from small commercial loads to large-scale industrial power demands.

Key Steps in the Cast Resin Manufacturing Process

The manufacturing quality of a cast resin transformer directly determines its electrical and mechanical performance. The core production steps include:

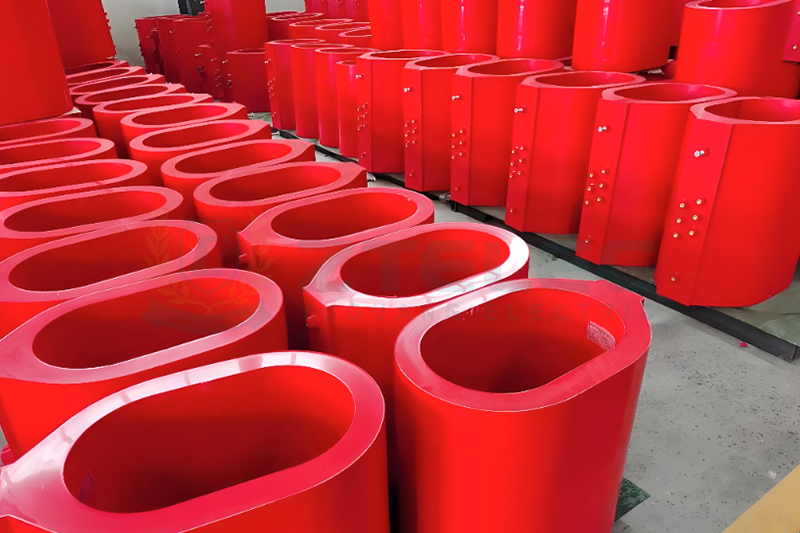

Winding and Pre-Assembly: High-voltage and low-voltage coils are precisely wound using copper or aluminum conductors and placed into dedicated molds. Cooling air ducts, leads, and mechanical supports are assembled simultaneously to ensure optimal heat dissipation and structural stability.

Vacuum Casting: Liquid epoxy resin is injected into the molds under vacuum conditions. This process fully impregnates all coil gaps, effectively eliminating air bubbles and reducing the risk of partial discharge.

Curing and Forming: The resin is heated and cured under controlled conditions, creating an integrated, high-strength insulation structure that firmly bonds the windings and resin into a single unit.

Key Features of the 10kV Cast Resin Structure

High Safety Performance: The absence of transformer oil eliminates the risks of leakage, fire, or explosion. Epoxy resin materials exhibit excellent self-extinguishing properties and high fire-resistance ratings, making these transformers suitable for indoor installation and densely populated areas.

Excellent Electrical and Mechanical Strength: Integrally cast windings provide strong short-circuit withstand capability and low partial discharge levels, ensuring stable long-term operation. The sealed structure offers effective resistance to moisture, dust, and environmental contamination.

Low Maintenance and Long Service Life: Under normal operating conditions, cast resin dry-type transformers require minimal maintenance. There is no need for oil testing or replacement, and the typical design service life reaches 20–30 years.

Advantages of the Insulation Structure

The reliable operation of a 10kV cast resin dry-type transformer depends on a high-performance insulation system. Key components include epoxy resin–cast windings forming the primary insulation barrier, composite insulation materials such as PET films and DMD used between winding layers, and glass fiber–reinforced structures that enhance mechanical strength.

Most designs adopt Class H or higher thermal endurance, allowing the transformer to maintain stable performance under high temperatures, overload conditions, and complex operating environments. Proper insulation material selection significantly improves operational reliability and service life.

Typical Application Scenarios

Thanks to its safety, compact structure, and environmental friendliness, the 10kV 30–4000kVA cast resin dry-type transformer is widely applied in urban distribution network upgrades, commercial complexes, high-rise buildings, and industrial manufacturing facilities.

It is also commonly used in renewable energy projects such as solar and wind power distribution systems. Its oil-free design and flexible installation make it particularly suitable for locations with limited space and stringent safety standards.

Selection and Installation Considerations

When selecting a cast resin dry-type transformer, capacity calculation should be based on actual load characteristics, diversity factors, and future expansion plans to prevent long-term overloading or unnecessary investment.

Energy efficiency is another critical factor. Attention should be paid to no-load and load loss values, with preference given to products that meet or exceed Level 1 energy efficiency standards.

Installation conditions such as ventilation, ambient temperature, and humidity must be evaluated to ensure compatibility with the transformer’s design parameters. It is also recommended to choose manufacturers with ISO-certified quality systems and complete type test reports, including short-circuit and temperature rise tests.

During installation, sufficient maintenance space should be reserved, grounding and wiring standards must be strictly followed, and protective enclosures should be installed when required by the environment.

The 10kV 30–4000kVA cast resin dry-type transformer combines high safety, excellent environmental performance, and reliable long-term operation. With proper selection and high-quality insulation design, it effectively supports stable power distribution while reducing maintenance costs over the equipment’s lifecycle.

For more detailed technical specifications, insulation structure options, or customized material solutions for this transformer type, please feel free to contact us for professional support.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri