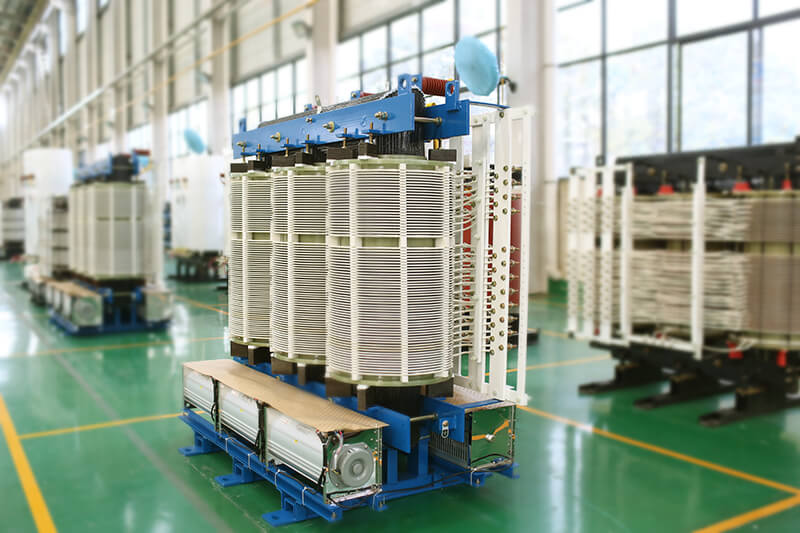

The features of dry transformer

This series of epoxy resin cast dry transformers are made of high-quality, western science and are produced strictly according to the process using advanced production testing equipment. The product has the characteristics of high reliability and long service life. Depending on the use environment, shells with different protection levels can be configured or not. Suitable for high-rise buildings, commercial centers, airports, tunnels, chemical plants, nuclear power plants, ships and other important or special environmental places.

The performance characteristics of dry transformer

1. Safety, fire prevention, pollution-free, can be directly operated in the load center;

2.Using Swiss T + M technology, high mechanical strength, strong short circuit resistance, small partial discharge, good thermal stability, high reliability and long service life;

3. Low loss, low noise, obvious energy saving effect, and maintenance-free.

4. Good heat dissipation performance, strong overload capacity, forced air cooling can increase capacity operation.

5. Good moisture resistance, suitable for operation in high humidity and other harsh environments.

6,Dry transformer can be equipped with a complete temperature and protection system, using intelligent signal temperature control system, can automatically detect and patrol the respective working temperature of the three-phase windings, can automatically start and stop the fan and have alarm, leisure and other functional settings.

7,Dry transformer has small size, light weight, less floor space, low installation costs.

Structural features of dry transformer

1. The high-voltage winding conductor is made of high-conductivity oxygen-free copper foil, the inter-turn insulation is made of F-grade insulation material and the imported glass grid plate is used as the skeleton inside and outside the winding. The copper foil and the turn insulation are programmed once on the high-voltage foil winding machine, controlled by a computer, the laser positioning and the lead wire is automatically welded by argon arc welding, wound in sections and then placed in a mold and cast with a resin with a filler under vacuum. forming.

2. Low-voltage winding of dry transformer uses copper foil with the same height as the high-voltage winding, together with F and turn insulation and is wound on the low-voltage foil winding machine. During winding, the copper wire of the winding leads is automatically welded out by argon arc welding and a brace is placed in the middle of the winding to form a cooling air channel. The end is potted with resin and solidified.

3. The core of dry transformer adopts high-quality grain-oriented cold-rolled silicon steel sheet, 45-degree full beveled seam and non-perforated iron yoke structure to ensure low no-load loss. The core clamping of dry transformer adopts the unique prestressed and breathable square steel clamp structure in China. The core is bound by insulating tape, the upper and lower clamps adopt the inner pull plate structure, and the surface of the core is sealed with a special resin which increases the structural strength and clamping force.

.png)

.png)

.png)