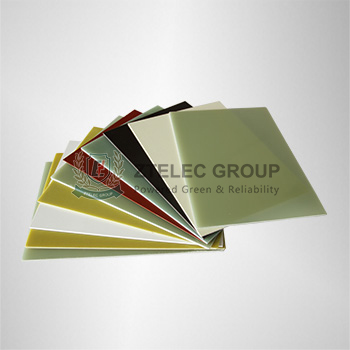

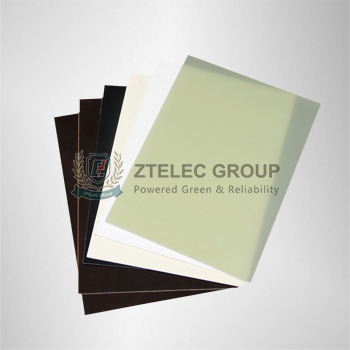

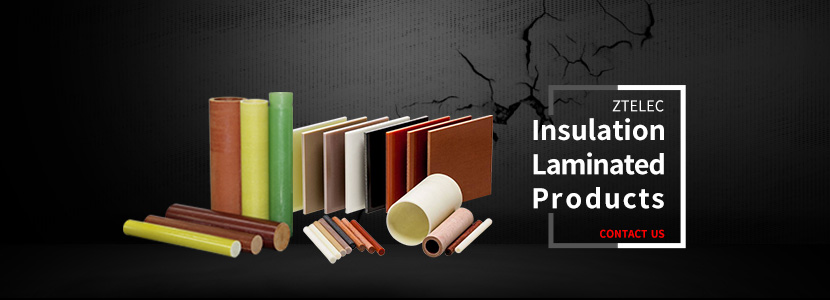

1. EPGC201/202/203/204/306/308 Epoxy glass fiber sheet

The product adopts 7628 glass fiber cloth impregnated with epoxy resin by hot pressing. It has high mechanical and electrical properties, good heat resistance and humidity resistance. Products are widely used on mechanical, electronic and electrical equipment as components of insulation parts. The product have higher mechanical properties, electrical properties and high thermal mechanical strength.

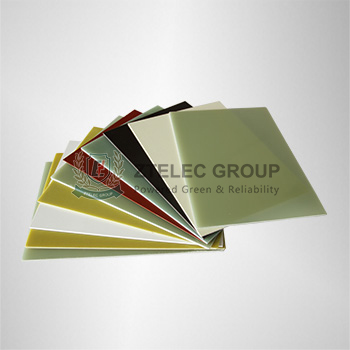

2. SIGC202/350/352/BMIGC301/302/PAIGC301 Silicone laminated glass fiber sheet

The product has the temperature grade of class H. It has higher mechanical strength, heat resistance, dielectric property, permeability, radiation resistance and flame resistance, which can be used for H-class motor and electrical appliance as components of insulation parts.

3. PFCP 202 Phenolic laminate paper-base sheet

This product is made of insulating paper impregnated with phenolic resin and is formed by baking and hot pressing. It has high mechanical and electrical properties. This product can be used as components of insulation parts for motors with higher mechanical performance and electrical equipment. It can also be used in the oil of transformer.

4. PFCC201/202/203/305 Phenolic laminate cotton cloth sheet

The product is made of cotton impregnated with phenolic resin and is formed by hot pressing, which has strong mechanical and electrical properties.

5. Semiconductor Laminated Glass Fiber Sheet 3241

This product has high mechanical and semiconductor properties and good heat resistance, and it is suitable for middle and large motor slot wedge as anti-corona material.

6. BMI GC302 Magnetic Laminated Glass Fiber Sheet

This product has high mechanical property, heat resistance and permeability, which is used as raw materials of magnetic slot wedge and widely used on large motors and wind turbines.

Technical Data

The product adopts 7628 glass fiber cloth impregnated with epoxy resin by hot pressing. It has high mechanical and electrical properties, good heat resistance and humidity resistance. Products are widely used on mechanical, electronic and electrical equipment as components of insulation parts. The product have higher mechanical properties, electrical properties and high thermal mechanical strength.

| IEC | Characteristic | |

| EPGC201 | High mechanical and electrical properties, good heat resistance, moisture resistance. | |

| EPGC202 | FR4 | Performance is similar to EPGC201; the flame retardance level is improved to UL F-V0. |

| EPGC203 | G10 | Performance is similar to EPGC201 and it has advanced heat resistance, high mechanical strength at high temperature, excellent electrical and anti-static properties. |

| EPGC204 | FR5 | Performance is similar to EPGC203; the flame retardance level is improved to UL F-V0. |

| EPGC306 | G11 | Performance is similar to EPGC203 and its proof tracking index is improved. |

| EPGC308 | Performance is similar to EPGC203 and its heat resistance is improved. It has well mechanical stability at high temperature. |

2. SIGC202/350/352/BMIGC301/302/PAIGC301 Silicone laminated glass fiber sheet

The product has the temperature grade of class H. It has higher mechanical strength, heat resistance, dielectric property, permeability, radiation resistance and flame resistance, which can be used for H-class motor and electrical appliance as components of insulation parts.

3. PFCP 202 Phenolic laminate paper-base sheet

This product is made of insulating paper impregnated with phenolic resin and is formed by baking and hot pressing. It has high mechanical and electrical properties. This product can be used as components of insulation parts for motors with higher mechanical performance and electrical equipment. It can also be used in the oil of transformer.

4. PFCC201/202/203/305 Phenolic laminate cotton cloth sheet

The product is made of cotton impregnated with phenolic resin and is formed by hot pressing, which has strong mechanical and electrical properties.

| IEC | Characteristic |

| PFCC201 | Coarse Cotton |

| Ordinary Mechanical and Electrical Properties | |

| PFCC202 | Middle Fine Cotton |

| Strong Mechanical and Electrical Properties | |

| PFCC203 | Fine Cotton |

| High Mechanical and Wear-resistant Properties | |

| PFCC305 | Electrical Thin Cotton |

| High Mechanical and Strong Dielectric Properties |

5. Semiconductor Laminated Glass Fiber Sheet 3241

This product has high mechanical and semiconductor properties and good heat resistance, and it is suitable for middle and large motor slot wedge as anti-corona material.

6. BMI GC302 Magnetic Laminated Glass Fiber Sheet

This product has high mechanical property, heat resistance and permeability, which is used as raw materials of magnetic slot wedge and widely used on large motors and wind turbines.

Technical Data

| Standard | GB/T 1303-2009 / IEC60893-2003 | ||||||||||||||||||

| Chinese Name | 3240 | 3250 | 350 | 352 | 3253 | 3021 | 3025 | 3025A | 3026 | 3027 | 3241 | ||||||||

| IEC | EPGC201 | EPGC202 | EPGC203 | EPGC204 | EPGC306 | EPGC308 | SIGC202 | - | - | BMI GC301 | BMI GC302 | PAIGC301 | PFCP202 | PFCC201 | PFCC202 | PFCC203 | PFCC305 | - | |

| NEMA | - | FR4 | G10 | FR5 | G11 | - | G7 | - | - | - | - | - | - | - | - | - | - | - | |

| Basic Material | Glass fiber cloth | Electronic Grade Glass Fiber Cloth | Glass Fiber Cloth/Electronic Grade Glass Fiber Cloth | Paper | Cloth | Glass Fiber Cloth | |||||||||||||

| Resin | Epoxy | Heat-resistant Epoxy Resin | Diphenyl Ether | Polyetherimide | Bismaleimide | Polyamide-imide | Phenolic | Epoxy | |||||||||||

| Color | Natural | Natural/Green | White / Light Green | Dark Brown | White | Brownish Red | Dark Brown | Red Brown | Brown | Black | |||||||||

| Test Item | Unit | Value | |||||||||||||||||

| Density | g/m³ | 1.8~1.95 | 1.25~1.4 | 1.3~1.4 | 1.75~1.90 | ||||||||||||||

| Vertical Layer Bending Strength (normal) |

MPa | ≥340 | ≥320 | ≥300 | ≥300 | ≥350 | ≥380 | ≥400 | ≥120 | ≥100 | ≥90 | ≥110 | ≥125 | ≥300 | |||||

| Parallel Layer Impact Strength (simply supported beam method) |

KJ/m2 | ≥38 | ≥45 | ≥42 | ≥38 | ≥60 | ≥60 | ≥60 | - | ≥7.8 | ≥50 | ||||||||

| Vertical Layer Electrical Strength (90℃transformer oil)(1mm thickness) |

Kv/mm | ≥14.2 | ≥8.0 | ≥8.0 | ≥14.0 | ≥14.0 | ≥14.0 | ≥14.0 | ≥15.8 | ≥5.1 | ≥5.1 | ≥5.1 | ≥5.1 | ≥8.0 | |||||

| Parallel Layer Breakdown Voltage (90℃transformer oil) |

kv | ≥35 | ≥35 | ≥40 | ≥35 | ≥40 | ≥35 | ≥35 | ≥35 | ≥40 | ≥35 | ≥40 | ≥40 | ≥35 | ≥20 | ≥35 | |||

| Dielectric Constant (50Hz) | - | ≤5.5 | ≤4.5 | ≤5.5 | ≤5.5 | ≤5.5 | ≤5.5 | ≤5.5 | ≤5.5(1MHz) | ||||||||||

| Dielectric Loss Factor(50Hz) | - | ≤0.04 | ≤0.02 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.03 | |||||||||||

| Insulation Resistance after Immersion | Ω | ≥5.0*1010 | ≥1.0*1010 | ≥1.0*1010 | ≥1.0*1010 | ≥1.0*108 | ≥1.0*108 | ≥1.0*108 | - | ≥5*107 | ≥1.0*108 | ||||||||

| Proof Tracking Index(PTI) | - | - | - | - | - | ≥200 | - | - | - | ≥300 | ≥280 | ≥280 | ≥500 | ≥100 | - | ||||

| Combustibility | - | - | V-0 | - | V-0 | - | - | V-0 | HB40 | - | - | - | - | - | HB40 | ||||

| Temperature Index | - | 130 | 130 | 155 | 155 | 155 | 180 | 180 | 180 | 180 | 180 | 180 | 200 | 120 | 120 | 155 | |||

| Water Absorption①(1-20mm thickness) | mg | 17~73 | 32~125 | 64~200 | 64-193 | 64~193 | 64~193 | 64~227 | 180~970 | 206~406 | 136~277 | 64-193 | |||||||

| Note:①Range values are measured for different thicknesses | |||||||||||||||||||

| A: (EPGC201/202/ 203/ 204 /306/308, SIGC202, 350, 352, BMIGC301/302, PAIGC301) | |||||||||||||||||||||||||||

| L*W(mm) | 2000*1000/1020*2020 (±20) 1000*1000(±10)(Magnetic Laminated Glass Fiber Sheet) | ||||||||||||||||||||||||||

| Thickness(mm) | 0.3 | 0.5 | 0.8 | 1 | 1.5 | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | 80 | 90 | 100 |

| Tolerance(±m) | |||||||||||||||||||||||||||

| A | 0.02 | 0.03 | 0.05 | 0.13 | 0.18 | 0.2 | 0.3 | 0.36 | 0.4 | 0.45 | 0.55 | 0.63 | 0.7 | 0.8 | 0.85 | 0.95 | 1.15 | 1.5 | 1.9 | 2.1 | 2.3 | 2.4 | 2.5 | 2.8 | - | - | - |

| 3025/3025-A | - | 0.08 | - | 0.2 | 0.24 | 0.26 | 0.31 | 0.36 | 0.42 | 0.46 | 0.55 | 0.63 | 0.7 | 0.78 | 0.85 | 0.95 | 1.1 | 1.22 | 1.34 | 1.45 | 1.55 | 1.65 | 2 | ||||

| 3026/3027 | - | 0.05 | - | 0.16 | 0.19 | 0.21 | 0.26 | 0.32 | 0.36 | 0.4 | 0.49 | 0.56 | 0.64 | 0.7 | 0.76 | 0.87 | 1.02 | 1.12 | 1.24 | 1.35 | 1.45 | 1.55 | 2 | ||||

| 3241 | - | 0.03 | - | 0.13 | 0.18 | 0.2 | 0.3 | 0.36 | 0.4 | 0.45 | 0.55 | 0.63 | 0.7 | 0.8 | 0.85 | 0.95 | 1.15 | 1.5 | 1.9 | 2.1 | 2.3 | 2.4 | - | ||||

| Magnetic Laminated Glass Fiber Sheet | - | - | - | 0.13 | - | 0.2 | 0.3 | 0.36 | 0.4 | 0.45 | 0.55 | 0.63 | - | ||||||||||||||

.png)

.png)

.png)