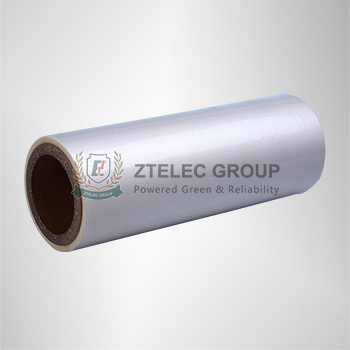

1. Polyester Film PET 6020(transparent)/6021(milky white) Class E

Description:

6020&6021is a biaxial oriented polyethylene terephthalate(PET)film made through melting, casting and stretching. This product has good dielectric and high mechanical properties. It is widely used for electrical insulation, such as slot insulation, interphase insulation and liner insulation in electric motors, and also used to produce insulating flexible laminates.

Package&Storage: Packed in rolls; store at room temperature; avoid fire. The storage period is 12 months.

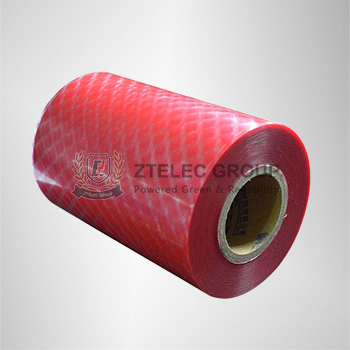

2. Diamond Glue Film Class E

Description:

This product is made by coating electrical insulation resin in the shape of diamond on single side or double side of polyester film which is then baked into a diamond glue film in the status of semi-curing. It is mainly used for layer and turn insulation of mutual inductor and transformer.

4. Polyimide Film Stripe/ Adhesive Tape Class H

Description:

Polyimide Film Adhesive Tape is made of polyimide film coated with heat resistant adhesive. It is an ideal insulating product for H class electrical equipment.

6020/6050 Technical Data

Note:The data in the above table only represents typical or average data, just for reference in practical application. It does not bear any responsibility for the use of the product or related legal liability.

Diamond Glu Film Technical Data

Note:The data in the above table only represents typical or average data, just for reference in practical application. It does not bear any responsibility for the use of the product or related legal liability.

Package&Storage: Packed in rolls; store at room temperature; avoid fire. The storage period is 12 months.

Description:

6020&6021is a biaxial oriented polyethylene terephthalate(PET)film made through melting, casting and stretching. This product has good dielectric and high mechanical properties. It is widely used for electrical insulation, such as slot insulation, interphase insulation and liner insulation in electric motors, and also used to produce insulating flexible laminates.

Package&Storage: Packed in rolls; store at room temperature; avoid fire. The storage period is 12 months.

2. Diamond Glue Film Class E

Description:

This product is made by coating electrical insulation resin in the shape of diamond on single side or double side of polyester film which is then baked into a diamond glue film in the status of semi-curing. It is mainly used for layer and turn insulation of mutual inductor and transformer.

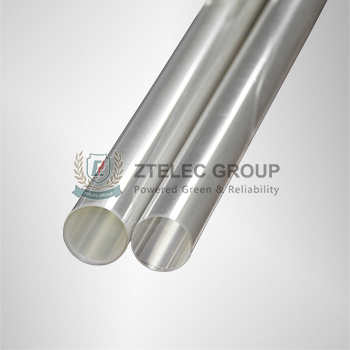

3. Polyimide Film 6050 Class H

Description:

H class Polyimide film is a common polyimide film condensed with 4- formic acid-2- anhydride of benzene, and 4.4-diamino-biphenyl-ether oxide. This product has excellent mechanical capability, favorable electric insulation at temperature from -269℃ to +260℃. It can be used in compound insulation material, adhesive tape, electric wire and motor industry, etc.

Package&Storage: Packed in rolls and in carton; store at room temperature; avoid fire. The storage period is 12 months.

4. Polyimide Film Stripe/ Adhesive Tape Class H

Description:

Polyimide Film Adhesive Tape is made of polyimide film coated with heat resistant adhesive. It is an ideal insulating product for H class electrical equipment.

6020/6050 Technical Data

| Item | Unit | 6020 GB/T13542.2-2009 IEC61074:1991 | 6050 GB/T13542.6-2006 IEC61074-2:1988 | ||||||||||||||||||||

| Thickness | um | 25 | 50 | 75 | 100 | 125 | 150 | 188 | 200 | 250 | 300 | 350 | 20 | 25 | 30 | 40 | 50 | 75 | 100 | 125 | |||

| Tolerance | ± | 5% | 4% | 6% | 3.0um | 4.0um | 5.0um | 7.5um | 10um | 12.5um | |||||||||||||

| Density | kg/cm3 | 1.39-1.40 | 1.42-1.49 | ||||||||||||||||||||

| Tensile Strength | MD | MPa | ≥150 | ≥140 | ≥140 | ≥150 | ≥120 | ||||||||||||||||

| TD | ≥120 | ||||||||||||||||||||||

| Elongation | % | ≥80 | ≥120 | ≥50 | ≥60 | ||||||||||||||||||

| Electrical Strength | V/um | 170 | 130 | 105 | 90 | 80 | 75 | 65 | 65 | 60 | 55 | 50 | 200 | 180 | 130 | 110 | 95 | ||||||

| Volume Resistivity | Ω.M | ≥1.0*1014 | ≥1.0*1013 | ||||||||||||||||||||

| Surface Resistivity | Ω | ≥1.0*1013 | ≥1.0*1015 | ||||||||||||||||||||

| Shrinkage(150℃) | % | ≤3.0 | ≤2.0 | - | ≤0.2 | ||||||||||||||||||

| Dielectric Loss Factor(50Hz) | - | ≤0.003 | ≤0.004 | ||||||||||||||||||||

Diamond Glu Film Technical Data

| No. | Properties | Unit | Index | ||

| 1 | Base Thickness | mm | 0.05±0.005 | 0.07±0.007 | 0.10±0.010 |

| 2 | Single-sided Plastic Grid Thickness | μm | 17.5±2.5 | ||

| 3 | Thermal Shrinkage Rate | % | ≤3 | ||

| 4 | Adhensive Strength | KPa | ≥350 | ||

| 5 | Tensile Strength | MPa | ≥150 | ||

| 6 | Elongation at Rupture | % | ≥80 | ||

| 7 | Power Frequency Breakdown Voltage | kv | ≥6.0 | ≥7.0 | ≥9.0 |

| 8 | Temperature Index(TI) | - | ≥130 | ||

Package&Storage: Packed in rolls; store at room temperature; avoid fire. The storage period is 12 months.

.png)

.png)

.png)