The features of resin-insulated dry-type transformers

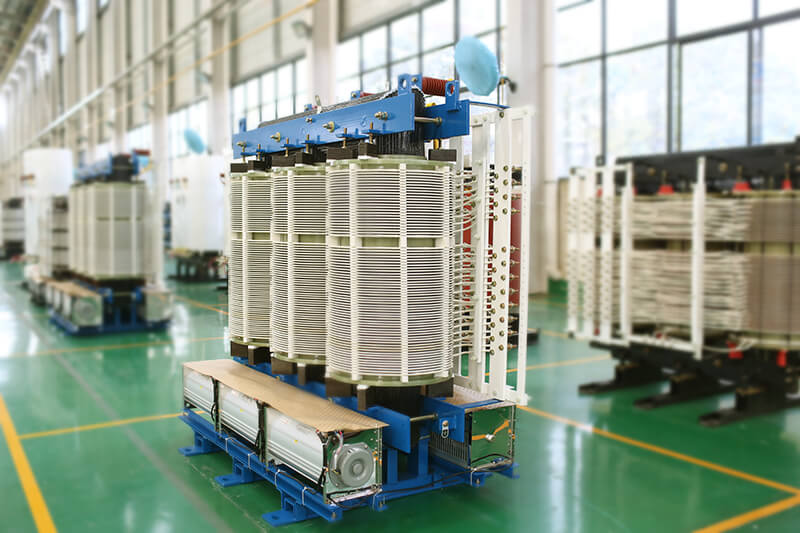

Resin-insulated dry-type transformers are our company's introduction of foreign advanced technology and independently developed SC9, SCB9 series and SC1O, SCB1O series of thin-film insulation dry-type transformers with fillers. Because the coil is encapsulated by epoxy resin, it is flame-resistant, fire-proof and explosion-proof. Maintenance-free, pollution-free, small size, can be directly installed in the load center. At the same time, the scientific and reasonable design and casting process make the product have a smaller partial discharge, low noise, and strong heat dissipation capacity. It can run for a long time at 140% of the rated load under forced air cooling, and is equipped with an intelligent temperature controller with failure. Alarm, over-temperature alarm, over-temperature trip and black brake function, and connected to the computer through RS485 serial interface, can be centrally monitored and controlled.

Because our company's resin insulated dry-type transformers have the above characteristics, they are widely used in power transmission and transformation systems. Such as hotels, airports, high-rise buildings, commercial centers, residential quarters and other important places, as well as subways, smelting power plants, ships, offshore drilling platforms and other environments. Harsh places.

The core of resin-insulated dry-type transformers

The core is made of imported high-quality cold-rolled silicon steel sheet, the core of resin-insulated dry-type transformers is made of imported high-quality cold-rolled silicon steel sheet, with a full miter end structure, the core is bound with F-level weft-free adhesive tape, and the core surface is encapsulated with epoxy resin to reduce no-load loss. No-load current and core noise. The clips and fasteners are treated with a special surface, which further improves the appearance quality of the product.

High voltage winding of resin-insulated dry-type transformers

High-voltage windings High-voltage windings are filled with vacuum resin with a filler ring, which greatly reduces the amount of partial discharge and improves the electrical strength of the coil. The ability to short-circuit, the coil will never crack.

Low voltage winding of resin-insulated dry-type transformers

The low voltage winding adopts a foil structure, which solves the problem of the axial helix angle when using wire winding to make the ampere turn more balanced. At the same time, the coil uses an axial cooling air duct to enhance the heat dissipation ability. cloth, solidified as a whole.

Manufacturing process of resin-insulated dry-type transformers

The coil is wound on a high-precision winding machine. The low-voltage winding of resin-insulated dry-type transformers uses a foil winding structure. When the transformer has a large capacity. It is dried after the air duct is wound. The entire casting and curing process is performed according to the process requirements. All processes are required. There is strict monitoring, and the precise manufacturing process of the pouring of the adjustment port is carried out according to the situation, so that the coil is free of air bubbles and cavities, so that the resin-insulated dry-type transformers can achieve high-quality operation results.

Temperature control system and air cooling system of resin-insulated dry-type transformers

A cross-flow top-blown cooling fan is adopted. The cooling fan has the characteristics of low noise, high wind pressure and beautiful appearance, which enhances the overload capacity of the transformer. Temperature control adopts intelligent temperature controller to improve the safety and reliability of transformer operation.

Protective housing and outgoing busbar of resin-insulated dry-type transformers

The protective shell protects the transformer for further safety. The protection grades of resin-insulated dry-type transformers are IPZO, IP23, etc. The shell materials are cold-rolled steel plates, stainless steel plates, etc. For users to choose the standard bus bar discharge line for low-voltage outlets. Both side outlets and ejectors can be used. Users design special outlets.

Transformer outlet of resin-insulated dry-type transformers

According to different interface forms, conventional outlets, standard closed busbars and standard side outlets can be manufactured and special outlet methods can be designed according to user requirements.

.png)

.png)

.png)