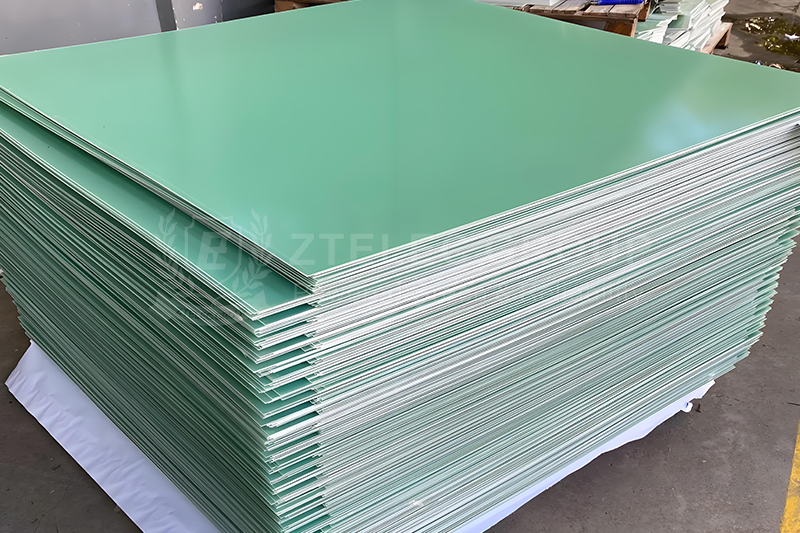

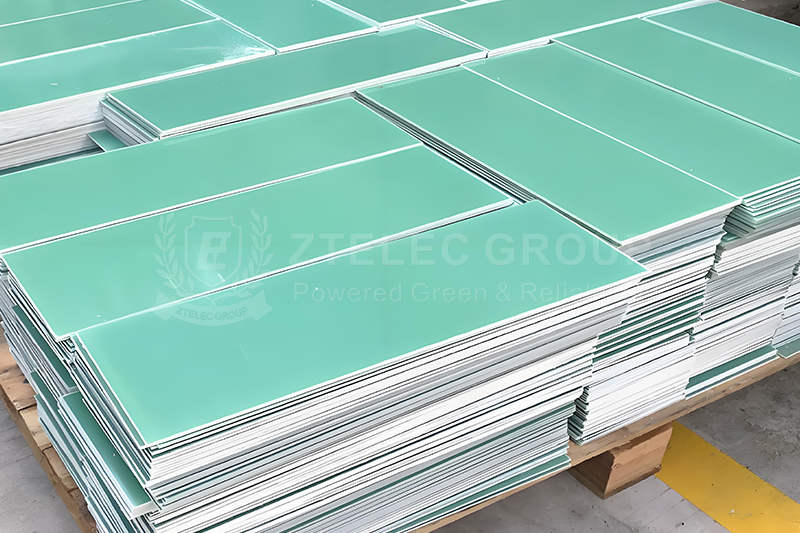

How FR5 Epoxy Laminate Enhances Durability in Harsh Environments?

In the modern industrial field, FR5 epoxy laminates are widely used in key industries such as aerospace, electronic equipment, and automobile manufacturing due to their excellent electrical insulation performance and mechanical strength. However, when it is in harsh environments such as high temperature, high humidity, chemical corrosion, and mechanical stress for a long time, its performance will decline, which will affect the reliability of the equipment and shorten the service life of the equipment. Therefore, exploring and implementing effective durability improvement strategies has become an important task to ensure the stable application of FR5 epoxy laminates. Based on industry research and practical experience, we can take measures from multiple dimensions such as material selection, process optimization, surface protection, environmental adaptability design, application scenario customization, and quality control and maintenance to comprehensively enhance its durability in harsh environments.

1. Material optimization

Epoxy resin modification

Epoxy resin is the core matrix material of FR5 epoxy laminates, and its performance directly determines the overall performance of the laminates. In high temperature environments, the stability of the laminates will be affected. In order to improve the stability of the laminates in high temperature environments, high temperature resistant curing agents such as phenolic resins and acid anhydrides can be added. These curing agents can form a stable cross-linked structure at high temperatures to resist thermal degradation.

At the same time, the introduction of flexible modifiers such as rubber particles can enhance the impact resistance of the laminate, making it less likely to crack when subjected to mechanical stress. In addition, the purity of the epoxy resin has an important impact on the durability of the laminate. Impurities will accelerate the degradation of the resin. Reducing the impurity content can reduce the risk of hydrolysis and improve the durability of the laminate.

After the addition of nanofillers such as silica and boron nitride, the performance of the laminate can be enhanced at the microscopic level. They are evenly dispersed in the resin matrix to form a support network, hinder the conduction of moisture and heat, and improve mechanical strength and moisture and heat resistance. After an electronic equipment manufacturer introduced nano-silica, the moisture and heat resistance of the FR5 epoxy laminate it produced increased by 20%.

Reinforcement material selection

In addition to epoxy resin, reinforcement materials are crucial to the performance improvement of FR5 epoxy laminates. Taking glass fiber cloth as an example, E-CR glass fiber cloth has more advantages than ordinary E-glass in acid and alkali corrosion resistance. In chemical industry applications, the service life of laminates using E-CR glass fiber can be extended by about 30%.

Under extreme environmental conditions, although aramid fiber or carbon fiber has high cost, it has excellent mechanical properties. When companies apply it in practice, they need to comprehensively consider cost and performance and make appropriate choices. For example, in the aerospace field, carbon fiber is often preferred due to high requirements for material performance; in the cost-sensitive manufacturing of ordinary electronic equipment, glass fiber cloth with high cost performance is often selected.

Flame retardant optimization

Flame retardant performance is an important indicator for measuring the safety of FR5 epoxy laminates. When selecting flame retardants, halogen-free flame retardants such as phosphorus are more suitable. It can not only meet the flame retardant requirements, but also avoid the release of corrosive gases by halogen flame retardants in hot and humid environments, prevent accelerated aging of laminates, and protect their durability and electrical properties.

2. Process Improvement

Lamination Process Control

During the production process of laminates, the lamination process directly affects the quality of the final product. To ensure that the epoxy resin is fully cured, a segmented curing process, such as a step-by-step heating method, is used to avoid residual internal stress and prevent problems such as warping and cracking of the laminate during use.

Using silane coupling agent to treat the fiber surface can enhance the interfacial bonding between the resin and the fiber, improve the interlayer bonding force, and make the laminate less likely to delaminate when subjected to external forces. After a circuit board manufacturer optimized the lamination process, the product yield rate increased from 85% to 95%.

Low porosity treatment

Porosity is the main way for moisture and corrosive media to invade the laminate, and reducing porosity is the key to improving durability. The vacuum pressurized lamination process can reduce the generation of bubbles and block the moisture penetration path. Post-curing treatment at 120℃ - 150℃ can increase the cross-linking density, make the laminate structure denser, and enhance its corrosion resistance and moisture resistance.

3. Surface protection

Coating protection

Surface coating protection is essential to enhance the resistance of FR5 epoxy laminates to external corrosion. Polyimide varnish and fluorocarbon coating can resist chemical corrosion and ultraviolet rays. In outdoor application scenarios, fluorocarbon coating can improve the weather resistance of laminates by more than 50%. Acrylic, polyurethane or silicone three-proof paint has good effects in moisture and salt spray resistance, and is suitable for equipment in coastal areas or high humidity environments.

Edge sealing

The cutting edge of the board is a weak point of the laminate and is prone to moisture intrusion. Using epoxy glue to seal the edge can prevent moisture from penetrating along the fiber, protect the internal structure, and ensure the overall performance of the laminate.

4. Environmental adaptability design

Structural design

Reasonable structural design can significantly improve the durability of FR5 epoxy laminates. Avoiding sharp corners during design can reduce stress concentration and prevent cracks from occurring and expanding. Increasing thickness or setting reinforcement ribs can improve the mechanical fatigue resistance of laminates, so that they can maintain good use conditions when subjected to mechanical stress for a long time.

Wet and hot cycle test

In order to ensure the stability of laminates in actual harsh environments, accelerated aging tests are required. Wet and hot cycle tests are carried out under conditions of 85℃or 85% RH to simulate the actual use environment and verify the material performance. According to the test results, the formula or process can be adjusted in time to ensure that the laminate meets the needs of different application scenarios.

Through multi-faceted collaborative strategies such as material optimization, process improvement, surface protection, environmental adaptability design, the durability of FR5 epoxy laminates in harsh environments can be significantly improved, providing guarantees for their stable application in more complex industrial scenarios. With the development of industrial technology, it is necessary to continue to explore and innovate to further improve the performance of FR5 epoxy laminates.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele