G10 Epoxy Sheet: The Preferred Insulation Material for the Electronics Industry

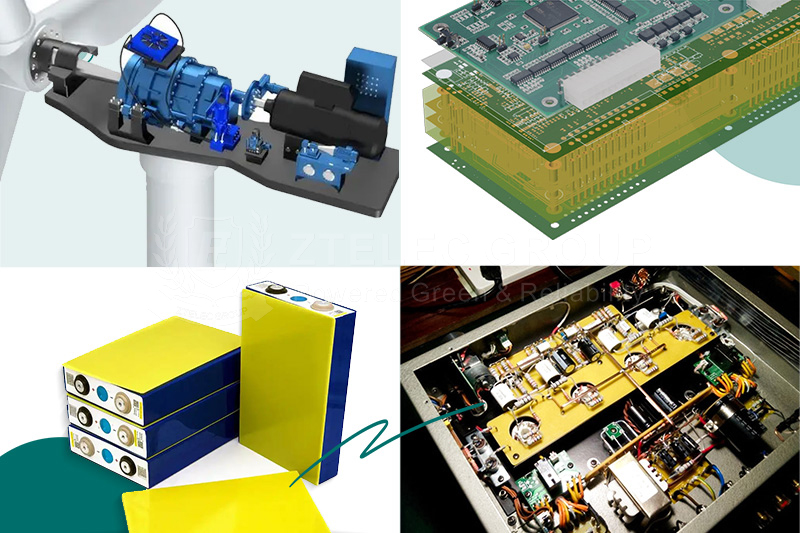

In the electronics industry, where precision and safety are crucial, material selection directly impacts product performance, service life, and operational safety. As a commonly used electronic insulation material, G10 epoxy sheet has long been the industry's choice due to its numerous excellent properties. It is primarily used in applications such as circuit board substrates, transformer insulation gaskets, and high-performance equipment components. This article will explain the definition, core advantages, and industry applications of G10 epoxy sheet to help companies select the appropriate material.

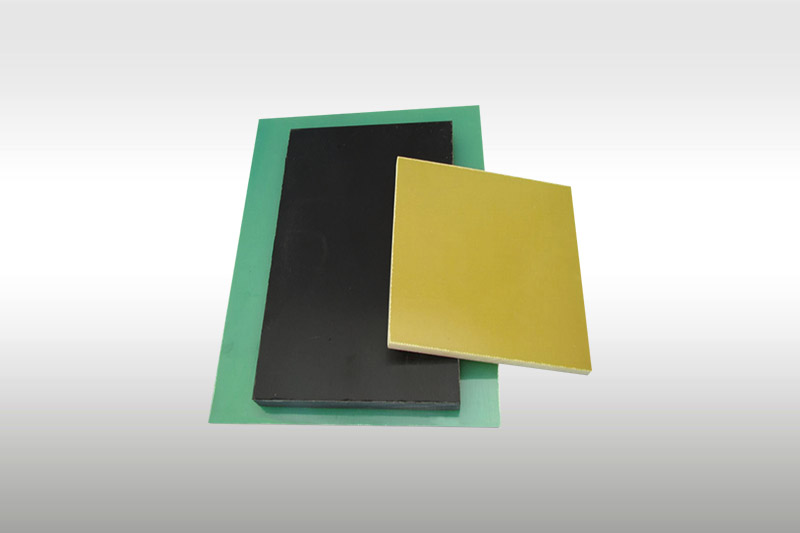

What is G10 epoxy sheet?

G10 epoxy sheet (also known as FR-4, or flame-retardant epoxy glass cloth laminate) uses continuous glass cloth as a reinforced substrate. After being fully impregnated with epoxy resin, it is cured at high temperature and high pressure to form a composite laminate. This manufacturing process determines its physical, electrical, and chemical properties, laying the foundation for its stable application in the electronics industry.

G10 Epoxy Sheet Core Advantages

1. Excellent Electrical Insulation

G10 epoxy sheet boasts high dielectric strength and a low dielectric constant, effectively isolating current and reducing electromagnetic interference. It is used for insulation in high-frequency, high-voltage electronic equipment such as transformers, capacitors, and power modules.

2. Strong Mechanical and Heat Resistance

G10 epoxy sheet offers high strength, impact resistance, and high-temperature resistance, allowing it to withstand the mechanical stress and heat generated by electronic equipment during operation. It can be used in the manufacture of components such as circuit boards, connectors, and device casings.

3. Good Environmental Adaptability

Moisture and Corrosion Resistance: G10 epoxy sheet's compact structure and low water absorption make it resistant to humid environments, preventing degradation of its insulation performance. It is also resistant to most chemicals, including acids, alkalis, and solvents, making it suitable for use in complex environments.

Environmentally Friendly and Recyclable: Production produces no harmful gases, meeting the environmental standards of the electronics industry. It supports recycling, reducing electronic waste pollution.

4. Dimensional Stability

G10 sheet has low expansion and contraction rates, making it suitable for applications requiring precise and stable mounting, such as measuring instruments and aerospace equipment.

G10 Epoxy Sheet Applications in the Electronics Industry

Insulation Gaskets: G10 epoxy sheet is used as insulation gaskets and isolation barriers in transformers, motors, and power supplies, ensuring equipment insulation safety.

Test Fixtures and Sockets: With its high strength and insulation properties, G10 epoxy sheet is used in in-circuit test (ICT) and flying probe test fixtures, ensuring a stable test process.

Electronic Component Structural Parts: G10 epoxy sheet can be processed into coil bobbins, insulated terminal blocks, switch gears, and busbar insulation components, meeting the structural support and insulation needs of various electronic components.

High-Performance Equipment: G10 epoxy sheet can be used in medical electronic equipment as insulation and structural components, adapting to extreme operating environments.

Recommendations for G10 Epoxy Sheet

Electronics companies can achieve three benefits by choosing G10 epoxy sheet:

Ensuring Product Safety: Excellent insulation properties reduce the risk of leakage and short circuits in equipment.

Extending Product Life: Strong mechanical, heat-resistant, and corrosion-resistant properties extend equipment life.

Reducing Costs: Easy processing makes it suitable for mass production. Recyclability reduces waste disposal costs.

To learn more about G10 epoxy board's technical specifications and request samples, contact us today to find the right insulation material solution for your electronic product design.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele