What is the Role of Electrical Laminated Wood in Transformer Insulation? Key Advantages

Electrical laminated wood is an engineered wood material specifically developed for electrical insulation applications. It is made from natural woods such as birch or maple, which undergo processes like resin impregnation and high-temperature, high-pressure lamination. The manufacturing process is precise and controlled:

Material Selection and Drying: Wood with stable mechanical properties is carefully selected and dried to remove moisture, preventing deformation during processing.

Resin Impregnation: Insulating resins such as phenolic or epoxy are used to penetrate the wood fibers, enhancing electrical performance and heat resistance.

Lamination: Multiple layers of impregnated wood are pressed under high temperature (120°C–180°C) and high pressure (5–15 MPa) to form a dense structure with aligned fibers.

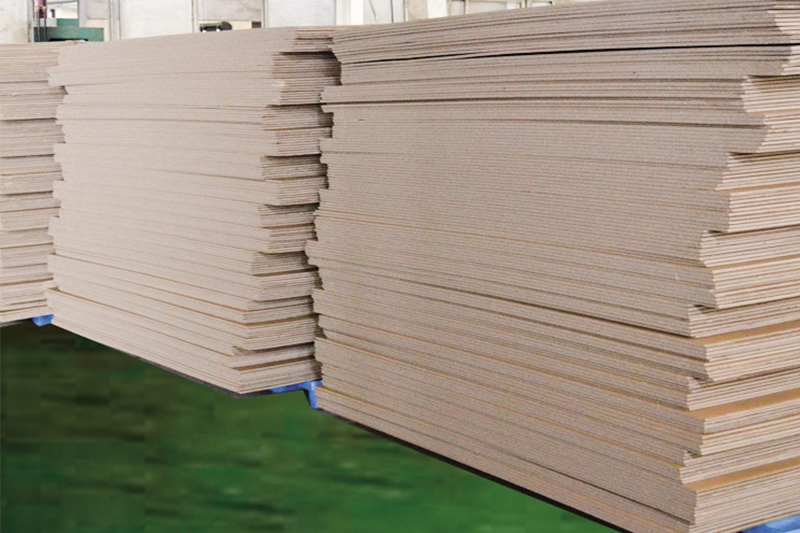

Post-Processing: The material is cut and polished into transformer insulation components such as blocks, spacers, and insulating boards.

The Role of Electrical Laminated Wood in Transformer Insulation Systems

1.Mechanical Support and Insulation

Acts as a support structure for windings, cores, and clamps, ensuring both mechanical strength and electrical insulation.

Withstands mechanical stresses (e.g., electromagnetic forces, vibrations) while preventing short circuits or discharges.

2.Isolation and Fixation

Voltage Isolation: Forms a physical barrier between high- and low-voltage windings to prevent short circuits.

Positioning Stability: Uses spacers and blocks to secure windings, preventing displacement and insulation wear, especially in high-load transformers with short-circuit resistance requirements.

3.Thermal Resistance and Stability

Maintains dimensional and insulating stability under long-term operating temperatures (105°C–130°C, corresponding to Class B/F insulation).

Its porous structure, combined with resin, improves thermal conductivity in oil by 15%–20%, aiding winding heat dissipation.

Key Advantages of Electrical Laminated Wood Over Other Insulating Materials

1.High Mechanical Strength

The lamination process aligns wood fibers, significantly enhancing compressive and flexural strength compared to ordinary wood or some plastics.

2.Superior Electrical Performance

Low dielectric loss and high dielectric strength reduce energy loss and withstand high electric fields, making it ideal for oil-immersed transformers (synergizing with insulating oil).

3.Thermal Stability & Aging Resistance

Resin impregnation and high-temperature pressing improve heat resistance (up to Class B or F insulation), preventing deformation, cracking, or carbonization during long-term operation.

4.Eco-Friendliness & Cost-Effectiveness

Uses renewable wood as a base material, making it more cost-effective than fully synthetic materials (e.g., epoxy) and easier to machine into complex shapes (e.g., blocks, spacers).

5.Oil Absorption & Compatibility

The porous structure readily absorbs transformer oil, forming an oil-paper composite insulation system that enhances insulation strength and heat dissipation.

6.Moisture Resistance & Chemical Stability

Resin treatment reduces moisture absorption, preventing degradation in oil and resisting acidic byproducts and temperature fluctuations.

Typical Applications of Electrical Laminated Wood

In oil-immersed power transformers, electrical laminated wood is widely used for:

Winding Support Structures: Such as yoke blocks and winding spacers, accounting for 20%–30% of transformer insulation weight.

Lead Insulation Components: Such as lead supports and insulating cylinders, ensuring spatial isolation of high-voltage leads.

Core Grounding Devices: Provides both insulation and mechanical fixation to prevent core ground faults.

With the development of ultra-high-voltage transformers (1,000 kV and above) and high-overload transformers, electrical laminated wood is evolving toward higher heat resistance (extending to Class H insulation), lower dielectric loss, and extreme-condition durability. Its applications in renewable energy transformers (wind, solar) are also expanding.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele