NHN vs. AHA Insulation: Key Differences and Which to Choose

In electrical equipment such as transformers and motors, the choice of insulation system directly impacts performance, lifespan, and safety. NHN and AHA are two common insulation material combinations, with significant differences in thermal resistance, mechanical properties, cost, and application scenarios. This article will provide a detailed comparative analysis of these two materials based on their technical characteristics, applicable scenarios, and selection criteria.

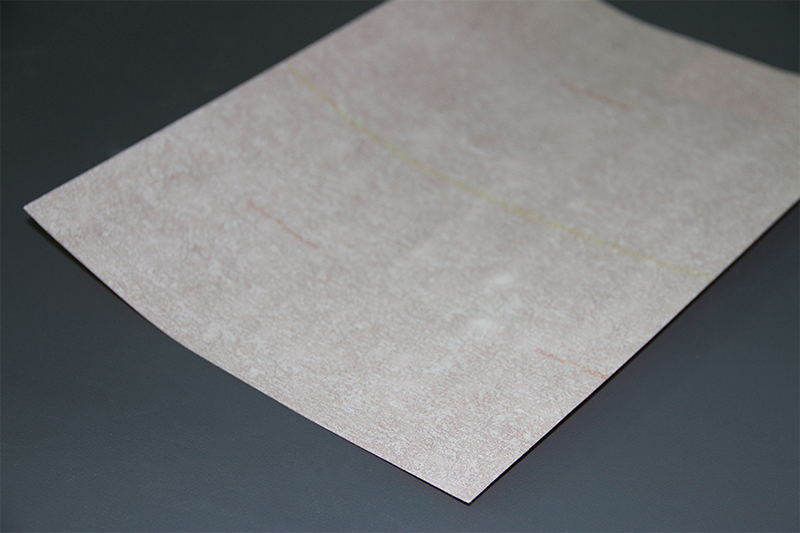

NHN Insulation

NHN utilizes a three-layer composite structure:

N (Nomex®): An aramid paper developed by DuPont, USA, offering excellent high-temperature resistance, flame retardancy, and high mechanical strength.

H (Polyester Film): Typically polyethylene terephthalate (PET), providing excellent electrical insulation and voltage resistance.

N (Nomex®): Nomex paper is used again to enhance mechanical support and overall thermal resistance.

A typical structure is: Nomex paper + polyester film + Nomex paper.

▶NHN Core Features

Heat Resistance:

NHN is Class H insulation (180°C), capable of long-term stable operation in high-temperature environments, with a short-term overload temperature of up to 220°C.

Mechanical Properties:

Nomex paper boasts a tensile strength over three times that of ordinary insulation paper, offering excellent tear and puncture resistance, making it suitable for environments subject to high vibration or mechanical stress.

Electrical Properties:

Polyester film offers high dielectric strength, while Nomex paper offers a stable dielectric constant, resulting in strong overall electrical reliability.

Flame Retardancy:

Nomex paper is inherently flame-retardant, self-extinguishing upon removal from flames, and complies with the UL94 V-0 standard, offering excellent safety.

Lifespan and Stability:

At Class H temperatures, NHN insulation has an expected lifespan of over 20 years, far exceeding that of conventional insulation materials.

▶Typical Applications:

High-temperature electrical equipment: Such as dry-type transformers, furnace transformers, and welding transformers.

High-mechanical stress applications: Such as rail transit traction transformers and wind turbine gearboxes.

Fields with high safety requirements: Such as nuclear power plants, petrochemical facilities, data center backup power supplies, etc.

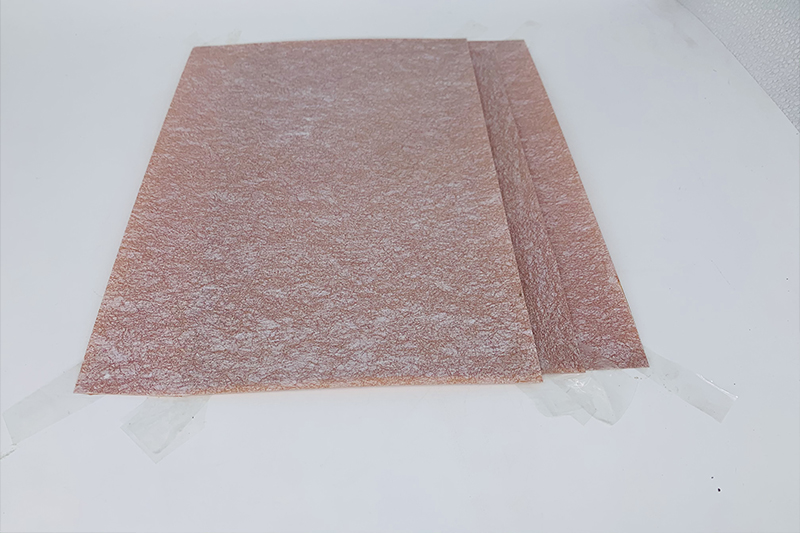

AHA insulation

AHA is typically a two- or three-layer composite material. Common structures include:

A (polyester film or polyimide film): Such as PET or PI film, it provides primary electrical insulation.

H (polyester fiber paper or Nomex paper): Such as the polyester fiber paper in DMD materials, or Nomex paper used directly to provide mechanical support.

A (polyester film or polyimide film): A film is used again to enhance overall insulation performance.

Typical structures include: PET film + polyester fiber paper + PET film, or polyimide film + Nomex paper + polyimide film (high-performance version).

▶AHA Core Characteristics

Heat Resistance Grade:

Ordinary AHA (PET-based) is typically Class E (120°C) or Class B (130°C);

High-performance AHA (containing polyimide and Nomex) can reach Class F (155°C) or Class H (180°C).

Mechanical Properties:

Polyester fiber paper has lower mechanical strength than Nomex, but through composite structural design, it can meet general industrial requirements.

Electrical Properties:

Polyester film offers excellent dielectric properties, while polyimide film offers even better dielectric properties (low dielectric constant and low loss).

Cost Advantage:

AHA material costs are typically 30%–50% lower than NHN, making it suitable for cost-sensitive applications.

Processability:

The material's excellent flexibility makes it easy to wind and form, making it suitable for complex coil structures.

▶Typical Applications

General-purpose motors and transformers: Such as household appliance motors, small industrial motors, and low-voltage distribution transformers.

Medium- and low-temperature equipment: Such as air conditioning compressors and fan motors.

Cost-focused projects: Such as mass-produced general-purpose equipment and export-oriented, low-value-added products.

NHN and AHA Insulation Selection Recommendations

When choosing NHN or AHA insulation materials, consider the following factors:

Core Performance Parameters

Temperature Resistance: Prioritize models that meet the equipment's long-term operating temperature requirements. For example, NHN should be selected for temperatures exceeding 220°C.

Mechanical Strength: In applications with high vibration or mechanical stress, choose NHN, which has superior mechanical properties, or achieve balance through composite structures.

Brands and Sourcing Channels

It is recommended to select reputable, certified manufacturers and avoid using non-standard or refurbished materials.

Pay attention to product packaging and storage conditions to ensure that the insulation material is free of moisture and damage.

Customization Requirements

If you have special requirements for size or slitting, confirm customization feasibility with the supplier in advance.

Price and Volume

Bulk purchasing can reduce unit prices, but be wary of possible material or aging issues with ultra-low-priced products.

Recommended Applications

Motors/Transformers: We recommend using NHN or AHA series composite materials for their optimal balance of temperature resistance and mechanical protection.

Electrical cabinets/precision electronics: AHA can be given priority as it performs better in terms of flame retardancy and economy.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer