Selection Guide for Yellow Epoxy Resin FR4 in Power Transformers

In the manufacturing of the core component of power transformers—the coil bobbin (also known as the winding frame)—the choice of insulation material is directly linked to equipment performance and safety. Among available materials, epoxy resin FR4 has become the mainstream option due to its unique advantages. This guide provides a comprehensive reference for transformer production, focusing on the properties, key selection factors, and certification requirements of yellow epoxy resin FR4.

Why Choose FR4 as the Bobbin Material for Transformers?

FR4 is not an ordinary insulation material. It is a laminated composite made from epoxy resin and electronic-grade fiberglass cloth. Its position as the preferred choice for transformer bobbins comes from its outstanding balance of multi-dimensional properties, reflected in the following six aspects:

Reliable Electrical Insulation

FR4 possesses very high volume and surface resistivity, effectively isolating the primary and secondary windings of the transformer and significantly reducing the risk of high-voltage breakdown.

Strong Mechanical Performance

With its high strength and rigidity, FR4 can withstand the tension and pressure of copper wires during automatic winding processes without deformation or cracking, ensuring a solid structural foundation within the transformer.

Excellent Thermal Stability

Standard FR4 typically has a glass transition temperature (Tg) above 130°C, enabling it to endure the continuous heat generated during transformer operation as well as withstand high-temperature processes such as wave soldering and reflow soldering.

Outstanding Flame Retardancy

The “FR” in FR4 stands for “flame retardant.” The material must meet the UL94 V-0 standard—meaning it can self-extinguish quickly once the ignition source is removed, greatly reducing the risk of fire propagation.

Flexible Processing Adaptability

FR4 is compatible with CNC machining, punching, drilling, and other processes, allowing efficient and precise fabrication of complex bobbin shapes to meet diverse transformer power ratings and design requirements.

Stable Environmental Resistance

FR4 exhibits strong resistance to humidity and common chemicals, ensuring that transformers can operate reliably in demanding environments while maintaining stable performance and a long service life.

Key Factors in Selecting Epoxy Resin FR4

When choosing the FR4 model, it is necessary to closely adhere to the transformer design specifications and international safety standards, and pay special attention to the following seven core technical parameters to avoid product hazards caused by parameter mismatch:

1.Thickness

As the most straightforward parameter, common specifications include 0.5 mm, 0.8 mm, 1.0 mm, 1.5 mm, and 2.0 mm. Selection should be based on transformer power rating, required creepage distance, and electrical clearance. Insufficient thickness may cause dielectric withstand tests to fail or result in inadequate mechanical strength.

2.Flame Retardant Rating

UL94 V-0 is the minimum entry-level requirement for electrical products and allows no compromise. This rating ensures that in the event of a transformer fault and fire, flames will not spread further, serving as a core safety safeguard.

3.Glass Transition Temperature (Tg)

Tg is the critical temperature at which a material transitions from a rigid state to a rubbery state. For conventional applications, Tg ≥ 130°C is required. For lead-free soldering (high-temperature processes) or transformers operating in high-temperature environments, medium- to high-Tg grades are recommended—Tg ≥ 170°C (medium Tg) or Tg ≥ 180°C (high Tg)—to maintain rigidity and dimensional stability under heat stress.

4.Comparative Tracking Index (CTI)

CTI measures a material’s resistance to surface tracking. Ratings range from Class I to V (with lower numbers indicating better performance). For transformers operating at high voltages or in humid conditions, materials with CTI ≥ 400 V (Class I) or higher (e.g., CTI 600) should be selected to prevent insulation failure caused by electrolytic carbonization on the surface.

5.Dielectric Strength

Expressed in “kV/mm,” this parameter indicates the voltage withstand capability per unit thickness. Higher values mean stronger insulation performance. It is a decisive factor in whether the bobbin can pass stringent high-voltage tests between primary and secondary windings (e.g., power frequency 3 kV/60 s).

6.Water Absorption

Typically required to be less than 0.1%. The lower the value, the better the performance. Low water absorption ensures that FR4 maintains stable insulation properties in humid environments, guaranteeing long-term operational reliability.

7.Peel Strength

If the bobbin pins are made from FR4 copper-clad laminates, peel strength is critical—it measures the bonding force between copper foil and substrate. This directly affects pin solderability and mechanical strength, preventing pins from detaching during insertion or soldering.

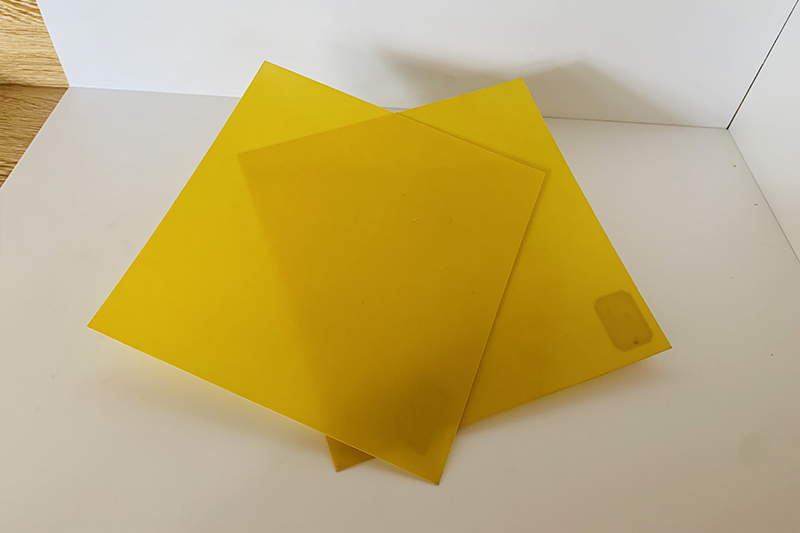

Special Considerations for Yellow FR4

Yellow is the standard color for epoxy FR4 in the transformer industry, with the primary advantage of simplifying identification and differentiation during production. Two points must be emphasized when selecting:

· Request a color sample from the supplier to confirm color consistency in mass production, preventing color variation from disrupting manufacturing processes.

· Verify the composition of the yellow pigment to ensure it does not negatively affect FR4’s core properties such as electrical insulation or heat resistance.

Safety Certification Requirements for FR4 Materials

Power transformers must pass multiple safety certifications, and as a core material, FR4 must also comply with the following certification standards to ensure market conformity:

UL Certification:

The material must be UL-certified and verifiable in the UL “Yellow Card” system. This serves as a key credential for entering international markets.

Environmental Compliance:

FR4 must comply with EU RoHS and REACH regulations, ensuring that the material is environmentally friendly, non-toxic, and aligned with global environmental requirements.

CQC Certification:

For the Chinese market, FR4 must be certified by the China Quality Certification Center (CQC) to ensure compliance with domestic power product safety standards.

Action Recommendation:

When selecting suppliers, always request the UL Yellow Card and Declaration of Conformity (DoC) documents for FR4 materials, and verify the authenticity and validity of the certifications.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer