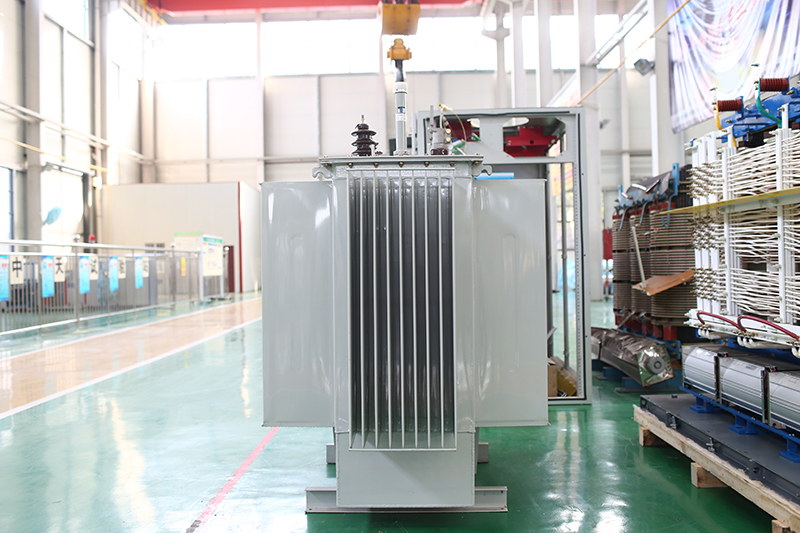

Oil Type Transformers: Price, Efficiency, and Performance Comparison (2025 Guide)

Price Analysis of Oil Type Transformers

Oil type transformers do not have a fixed price. Their cost varies significantly based on capacity, voltage rating, raw material quality, loss levels, brand, and optional configurations. For example, a medium-voltage 10kV/0.4kV distribution transformer may cost from tens of thousands to several hundred thousand RMB. Large-scale high-voltage or ultra-high-voltage transformers may reach several million RMB, with certain special designs exceeding ten million RMB.

Key Factors Influencing Price

Capacity Rating (kVA/MVA): Larger capacity requires more copper, silicon steel, insulation, and transformer oil. For example, a 1000kVA transformer is much more expensive than two 500kVA units combined.

Voltage Rating (kV): Higher voltage levels demand stricter insulation, advanced coil structures, and premium bushings. At equal capacity, a 110kV transformer is far costlier than a 10kV unit.

Raw Material Quality: Copper windings ensure higher efficiency and load capacity compared to aluminum but cost more. High-grade oriented silicon steel with laser scribing lowers no-load losses but increases unit cost.

Loss Level (Energy Efficiency Class): According to GB 20052 and IEC 60076 standards, transformers are divided into efficiency levels. Level 1 transformers, though 20%–40% more expensive than Level 3, offer significant long-term energy savings.

Brand and Manufacturing Process: Leading manufacturers such as ABB, Siemens, Schneider, TBEA, and XD Group charge premium prices due to advanced design, strict quality control, and reliable after-sales service.

Optional Configurations: Tap changer type, cooling system (ONAN, ONAF, OFAF), IP protection grade, and smart monitoring systems (like DGA analysis) all add to transformer cost.

Therefore, transformer selection should be based on comprehensive cost, considering purchase price, lifetime energy loss, and maintenance costs over a 30-year life cycle.

Efficiency Analysis of Oil Type Transformers

Efficiency is a critical performance index directly affecting electricity expenses. Oil type transformers generally achieve 95%–99.7% efficiency.

Efficiency Losses

No-load loss (core loss, P₀): Exists whenever energized, mainly caused by hysteresis and eddy currents in the silicon steel core. Choosing high-performance silicon steel greatly reduces these losses.

Load loss (copper loss, Pₖ): Caused by resistance in windings, proportional to load current squared. Copper windings with optimized design reduce this significantly.

High-Efficiency Transformer Features

High-grade silicon steel (30ZH120, 27QG100) or amorphous alloy cores minimize no-load loss. Large-purity copper conductors reduce load loss. Step-lap core design and optimized magnetic distribution improve overall efficiency.

For applications with continuous heavy loads, such as power station transformers, high-efficiency models deliver faster return on investment. For intermittent or light-load applications, balancing cost and efficiency is recommended.

Performance Analysis of Oil Type Transformers

Insulation Performance

Insulating oil provides excellent dielectric strength, moisture isolation, and thermal conductivity. It reduces insulation distance, lowers production cost, and prolongs service life by protecting windings and cores.

Cooling and Protective Performance

Oil immersion ensures uniform cooling, reduces core losses, and adapts to volume changes through corrugated oil tanks, eliminating the need for an external conservator. This design improves reliability and reduces maintenance complexity.

Structural Strength

Vacuum-dried cores and coils ensure minimal moisture and stable operation. Multi-layer cylindrical winding structures enhance short-circuit resistance and mechanical strength, allowing safe transport and reliable operation.

Environmental Adaptability

Oil type transformers perform well indoors and outdoors between -25°C and +40°C, suitable for diverse environments. Standard designs are rated up to 1000m altitude, with special adjustments required for higher altitudes.

Oil type transformers remain one of the most widely used power equipment solutions for distribution and transmission systems. When evaluating price, efficiency, and performance, decision-makers should prioritize life-cycle cost over upfront investment. By carefully analyzing capacity, efficiency class, and application requirements, businesses can achieve optimal economic performance and reliable power supply.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer