Specific Applications of Glass Fiber Wound Tube in Dry-Type Transformers

As power equipment continues to evolve toward high reliability and long life, dry-type transformers, with their outstanding advantages such as fire and explosion resistance and low maintenance costs, have become core power supply equipment in key sectors such as data centers, rail transit, and industrial manufacturing. Among the core components of dry-type transformers, glass fiber wound tube, with its unique material properties and sophisticated process design, not only significantly enhances the equipment's electrical performance but also effectively improves operational stability. This article will deeply analyze the specific application scenarios, implementation process, and core advantages of glass fiber wound tube in dry-type transformers.

Core Advantages of Glass Fiber Wound Tube

As a key insulating component in dry-type transformers, glass fiber wound tube is widely used due to its four core advantages:

1.Excellent insulation performance: As a high-quality electrical insulator, it effectively isolates current and ensures safe and reliable equipment operation.

2.High mechanical strength: The material is tough and durable, and even under high tension during coil winding, it is not prone to deformation or cracking.

3.High-temperature resistance: It can withstand the high temperatures encountered in transformer operation, and its service life is highly comparable to other components, preventing local damage from affecting the entire equipment.

4.Flame-retardant and moisture-proof: It is non-flammable and effectively resists moisture erosion, making it suitable for a variety of complex work scenarios.

Main Applications of Glass Fiber Wound Tube in Dry-Type Transformers

Glass-fiber wound tube is primarily used in two key areas of dry-type transformers, each fulfilling distinct functional responsibilities:

1. As the Main Insulator

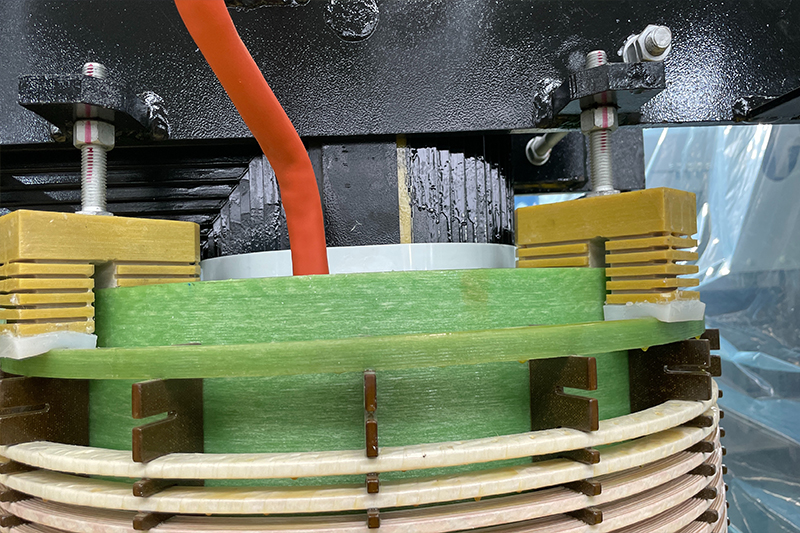

This is the primary and most common application of glass-fiber wound tube, primarily providing insulation protection between the core and the low-voltage winding.

Installation Location: Sleeved around the outside of the transformer core, between the core and the low-voltage (LV) winding.

Core Function:

Main Insulation Barrier: Glass-fiber wound tube builds the critical insulation barrier between the core and the LV winding, which is capable of withstanding the LV winding's power frequency withstand voltage and impulse withstand voltage tests to ground.

Mechanical Support: Glass-fiber wound tube provides a sturdy, precisely dimensioned cylindrical base for winding the LV winding. Winding machines can directly wind the LV coil (usually copper foil or flat copper wire) onto the smooth surface of the tubing.

Integral Load-Bearing Structure: During transformer assembly, it supports the weight of the LV winding, the HV winding, and the entire transformer body.

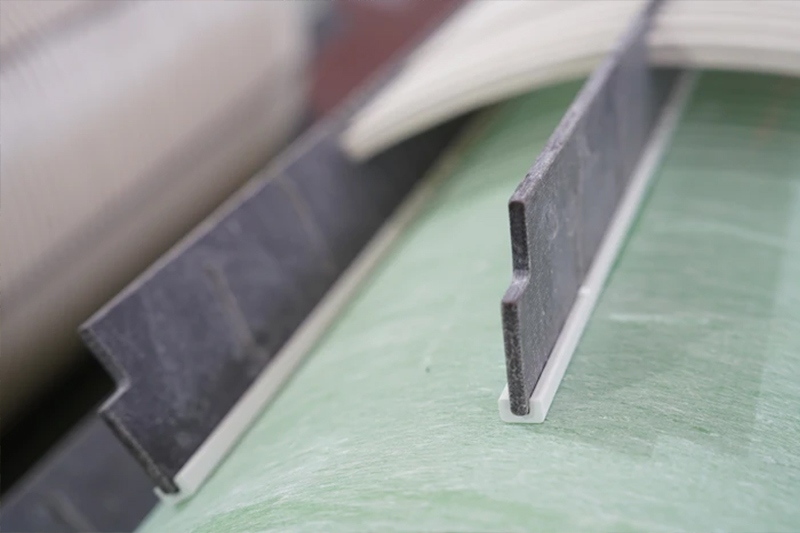

2. As a stay or air duct

In dry-type transformers with specialized structures or large capacities, thinner glass fiber-wound tube is used as a stay or air duct, primarily for insulation and cooling between the high-voltage and low-voltage windings.

Installation Location: The glass fiber wound tube is sleeved on the outside of the transformer core column, that is, between the core and the low-voltage (LV) winding.

Core Function:

Interval Insulation: Serves as the primary insulation component between the high-voltage and low-voltage windings, ensuring electrical safety between the two windings.

Cooling Air Duct Construction: Through the thickness of the tube wall itself, standard insulation distances and cooling air ducts can be naturally formed, ensuring timely heat dissipation from the transformer interior.

Typical Application Process for Glass-Fiber Wound Tube

Using glass-fiber wound tube as the main insulation tube as an example, the complete implementation process is as follows:

1. Preliminary Preparation: Prefabricated epoxy fiberglass tubes are precisely placed on the transformer core legs.

2. Coil Winding: Low-voltage coils (made of copper foil or wire) are wound on the fiberglass tube using a winding machine.

3. Insulation Treatment: Targeted insulation reinforcement is performed on the wound low-voltage winding, such as wrapping an insulation layer.

4. High-Voltage Winding Installation: Pre-wound and cured high-voltage windings are placed over the low-voltage windings and the fiberglass tube.

5. Body Curing: The entire body is placed in an oven for curing to ensure a tight bond between all components.

6. Final Assembly and Commissioning: The cured body is installed in the transformer housing, and lead connections and accessory installation are completed.

Glass-fiber wound tube, through the deep integration of materials science and process innovation, not only solves traditional challenges in dry-type transformers in terms of insulation, heat dissipation, and mechanical stability, but also promotes the upgrade of power equipment towards high reliability, low maintenance, and green features. With the widespread adoption of intelligent manufacturing technologies, the customized production capacity of glass-fiber wound tube will be further enhanced, providing critical infrastructure support for the global energy transition. For transformer manufacturers, mastering the core technology of glass-fiber wound tube has become a strategic priority for seizing the high-end market and is of great significance to the development of the industry.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele