6-10kV High Voltage Switchgear Cabinet for Medium-Voltage Power Systems

This article explains the design principles, technical features, applications, installation and maintenance guidelines, and selection considerations for a 6-10kV high voltage switchgear cabinet intended for medium-voltage power systems. Whether you are specifying equipment for a substation, industrial plant, commercial complex, or utility feeder, this guide highlights the practical benefits, compliance requirements, and performance criteria that ensure reliable, safe, and efficient power distribution.

What is a 6-10kV High Voltage Switchgear Cabinet?

A 6-10kV high voltage switchgear cabinet is an assembled cabinet that contains switching devices, protection relays, instrument transformers, earthing switches, busbars and wiring for medium-voltage power distribution. It performs switching, protection, measurement, metering and isolation functions at rated voltages typically between 6 kV and 10 kV. The cabinet design integrates electrical functional units and provides mechanical protection, arc containment and safe access for operation and maintenance.

Core Applications and Typical Use Cases

Common applications include primary distribution in utility substations, secondary distribution for industrial facilities and factories, power supply systems for rail and metro, commercial building complexes and data centers, distributed generation interconnection points for wind and solar farms, and mine power networks. The 6-10kV range is particularly suited for medium-voltage feeder lines and step-down distribution to transformers feeding low-voltage loads.

Key Design Features and Technical Highlights

Rated voltage and frequency: Designed for continuous operation at nominal system voltages from 6 kV up to 10 kV and standard frequencies (50/60 Hz) with insulation clearances and busbar mechanical strength sized accordingly.

Switching devices: Air-insulated circuit breakers, vacuum circuit breakers or gas-insulated modules are commonly used. Vacuum circuit breakers are preferred where compactness and low maintenance are required.

Protection and control: Modern cabinets integrate microprocessor protective relays for overcurrent, earth-fault, over/under voltage and distance protection. Metering and SCADA-compatible communication interfaces (e.g., Modbus, IEC 61850) are available for remote monitoring and automation.

Arc protection and safety: Cubicle partitions, arc-resistant layouts and pressure relief paths are engineered to limit arc flash energy and to protect personnel. Interlocks, earthed compartments and clear operating sequences reduce human-error risks.

Thermal and mechanical design: Busbar cross-sections, forced ventilation or natural convection, and thermal sensors ensure sustained performance under rated and short-circuit loading conditions.

Standards, Compliance and Quality Assurance

Switchgear cabinets for the 6-10kV range are designed in accordance with internationally recognized standards to ensure safety, interoperability and predictable performance. Common standards referenced include IEC 62271 series for high-voltage switchgear and controlgear and IEC 60068 for environmental testing. When supplying for specific markets, compliance with regional standards such as ANSI/IEEE, GB, or local utility technical specifications may be required. Factory acceptance testing (FAT), routine testing of components, type tests and site acceptance testing (SAT) form part of the quality assurance process.

Typical Technical Specification Summary

| Parameter | Typical Value / Range |

|---|---|

| Rated voltage | 6kV / 7.2kV / 10kV |

| Rated frequency | 50Hz or 60Hz |

| Rated current | Up to 4000 A (busbar dependent) |

| Rated short-circuit current | 20kA to 50kA for 1s (customizable) |

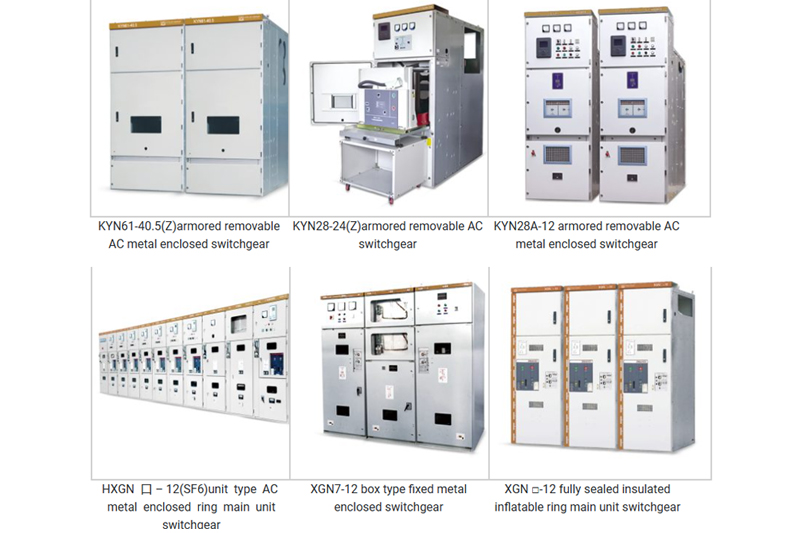

| Switchgear type | Metal-clad, metal-enclosed, air-insulated, vacuum circuit breaker |

| Protection | Overcurrent, earth-fault, distance, breaker failure, interlocking, SCADA ready |

| Enclosure protection | IP3X to IP54 options; anti-corrosion treatment available |

Advantages of Choosing a Modern 6-10kV Switchgear Cabinet

Modern switchgear cabinets bring several advantages that make them preferable in new installations and retrofit projects. They deliver compact footprints for space-constrained substations, modular designs that simplify upgrades, and advanced protection and communication capabilities that enable faster fault detection and restoration. Improved thermal design and high-quality components translate into longer service life and reduced lifecycle costs. Safety features such as arc-resistant construction and grounding interlocks reduce downtime and protect personnel and assets.

Installation and Commissioning Considerations

Proper installation and commissioning are critical to achieve rated performance. Key steps include verifying foundation and leveling, ensuring correct busbar alignment and clearances, checking cable terminations, carrying out secondary wiring and functional tests for protection relays, and performing primary injection and insulation resistance tests. Coordination studies between upstream and downstream protection devices should be completed prior to energization. A detailed commissioning checklist and FAT / SAT documentation will support handover to operation teams and simplify warranty processes.

Operation, Monitoring and Maintenance Best Practices

Routine maintenance typically covers visual inspections, operating mechanism lubrication, contact wear measurements, infrared thermography of busbars and connections, protective relay testing and firmware updates, and periodic cleaning of ventilation or filter systems. Continuous online monitoring of temperatures, partial discharge and key electrical parameters enhances predictive maintenance and reduces forced outages. A recorded maintenance log, spare parts list and trained personnel with clear safety procedures are essential for reliable long-term operation.

Selecting the Right Switchgear: A Practical Guide

Selection should begin with load assessment and short-circuit calculations. Determine whether a metal-clad or metal-enclosed solution is required based on site environmental conditions and safety preferences. Decide on the preferred switching technology—vacuum circuit breakers for lower maintenance and better arc interruption performance, or SF6 / gas-insulated modules where extreme compactness and environmental sealing are needed (taking account of regulatory considerations). Ensure protection relay functionality matches grid code and utility protection coordination requirements, and verify communication protocols for SCADA integration.

Environmental and Site-Specific Factors

Consider ambient temperature range, altitude, humidity, corrosive atmospheres and seismic requirements when specifying the cabinet. Enclosure surface treatments and corrosion-resistant materials extend service life in coastal or industrial sites. For high-altitude installations, derating of insulation and air clearances may be necessary. For outdoor installations, ensure appropriate sheltering, drainage and HVAC if specified.

Common Customizations and Optional Features

Manufacturers offer options such as extended busbar ratings, front and rear cable access, integrated metering panels, redundant protection schemes, DC control power supplies with battery backup, harmonic filtering interfaces, and advanced human-machine interfaces (HMIs). Special features like arc flash mitigation systems, remote-communication gateways and modular plug-in units for rapid replacement can be included to meet operational targets and emergency response plans.

Cost Considerations and Total Cost of Ownership

Initial procurement cost is only one part of the equation. Lifecycle costs include installation, commissioning, maintenance, spare parts, energy losses and downtime. Investing in higher quality components and advanced monitoring often reduces total cost of ownership through extended service intervals, reduced failure rates and faster fault recovery. Tailor the procurement specification to balance upfront capital with long-term reliability and maintainability goals.

Conclusion and Next Steps

A well-specified 6-10kV high voltage switchgear cabinet is a backbone element of reliable medium-voltage power systems. By focusing on proven switching technologies, comprehensive protection schemes, compliance with international or regional standards, and robust safety and maintenance strategies, engineering teams can deliver resilient power distribution for substations, industrial plants and critical infrastructure.

If you would like a tailored specification sheet, a comparison between vacuum and SF6 solutions, or an editable datasheet for your procurement package, contact our technical team for a custom proposal.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele