Innovations and Breakthroughs in Dry-Type Transformer Standards

In the field of power transmission and distribution, transformers play a critical role in ensuring reliable energy delivery. Among them, dry-type transformers are gaining momentum due to their safety, reliability, and environmental advantages. Recent years have seen remarkable progress in materials, structural design, digitalization, environmental performance, and energy efficiency. This article explores these breakthroughs in detail.

1. Advanced Material Technologies

High-Performance Insulating Materials

Nano-Modified Resins: By incorporating nanoparticles (e.g., SiO₂) into epoxy resins, mechanical strength, thermal conductivity, and partial discharge resistance are significantly enhanced. These improvements help extend transformer lifespan and reduce maintenance needs, particularly in high-voltage, high-load environments.

Bio-Based Insulation: Environmentally friendly insulating materials derived from renewable sources—like plant oil-based resins—offer biodegradability and reduce the ecological footprint of transformers, aligning with global sustainability goals.

High-Temperature Resistance: Insulation systems rated for H-class (180℃) or higher enable better overload tolerance, ensuring consistent operation under fluctuating load conditions and improving grid reliability.

Low-Loss Core Materials

Amorphous Alloy Core: These cores reduce no-load loss by up to 80% compared to conventional silicon steel. Although limited by cost and brittleness, new manufacturing methods are being developed to overcome these challenges.

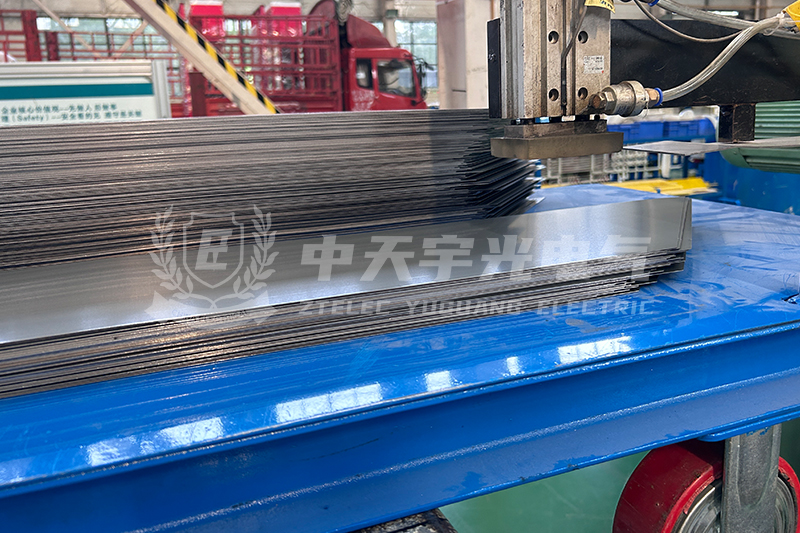

Ultra-Thin Oriented Silicon Steel: With thickness under 0.18mm, these materials reduce eddy current loss and improve efficiency in high-frequency power systems.

2. Structural Design and Heat Dissipation

3D Printing Technology

3D printing allows the creation of complex winding and cooling structures, such as bionic fins, enhancing heat dissipation and enabling transformers to operate reliably under high loads.

Modular Design

Standardized modules enable fast customization, reduce manufacturing cycles, and lower costs. Modular transformers can be quickly adapted to suit diverse power applications and load requirements.

Next-Generation Cooling Techniques

Phase Change Cooling: Using evaporative media like fluorinated liquids, this method increases cooling efficiency by over 30%, making it ideal for large-capacity transformers.

Heat Pipe Technology: By transferring heat efficiently to external radiators, this approach ensures stable performance in confined or poorly ventilated environments.

3. Intelligence and Digital Transformation

IoT and Built-In Sensors

Multi-parameter sensors (temperature, vibration, partial discharge, humidity) integrated into transformers support real-time monitoring. With AI-driven predictive maintenance, failures can be prevented before they occur.

Digital Twin Technology

Digital twins replicate physical transformers in a virtual environment, enabling simulation of operation and testing of maintenance strategies without disrupting service.

Edge Computing

Edge computing empowers transformers to process data locally, reducing cloud dependence. This ensures faster response times, improves reliability, and enhances cybersecurity.

4. Environmental Protection and Sustainability

Halogen-Free Flame Retardants

Non-toxic flame retardants based on phosphorus and nitrogen reduce harmful emissions during transformer fires, enhancing safety for personnel and minimizing environmental impact.

Recyclable Design Concepts

Designs that facilitate material separation and recovery—such as segmented epoxy resin structures—enable efficient recycling and resource conservation.

Noise Reduction

Low-magnetostriction core materials and active noise cancellation technologies reduce noise to below 45dB, enhancing the comfort of residential and public spaces.

5. Energy Efficiency Standard Advancements

Super First-Class Energy Efficiency

Transformers meeting this new standard exhibit 15–20% lower no-load and load losses, significantly reducing energy consumption and supporting emission reduction efforts.

Wideband Adaptability

Transformers with wideband capabilities are designed to handle high-frequency harmonics common in renewable energy systems, ensuring stable operation and enhanced power system compatibility.

From high-efficiency core materials to intelligent monitoring systems and sustainable design innovations, dry-type transformer technology is undergoing a transformative evolution. These advancements are not only enhancing performance and reliability but also playing a vital role in meeting global energy efficiency and environmental goals.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele