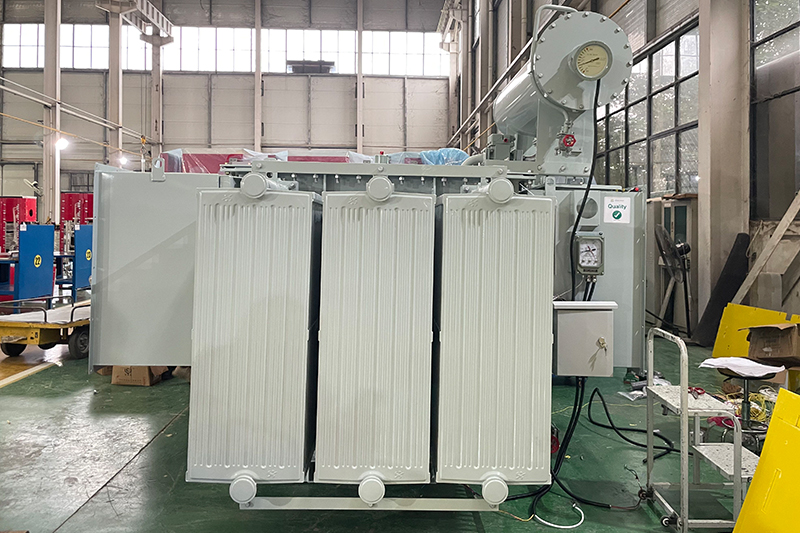

A Complete Guide to Common Oil-Immersed Transformer Fault Analysis and Solutions

Oil-immersed transformers are critical components of modern power systems, ensuring stable voltage conversion and energy transfer. However, during long-term operation, factors such as aging, environmental stress, and high load can lead to various faults. This guide explains the most common oil-immersed transformer faults, their causes, and effective diagnostic and maintenance solutions to minimize downtime and extend equipment lifespan.

Abnormal Transformer Oil Quality

Transformer oil serves as insulation, cooling, and arc extinguishing medium. Deterioration or abnormal oil conditions often signal early transformer issues, typically manifested as irregular oil level, temperature, or aging characteristics.

Abnormal Oil Level

An excessively high oil level is often caused by internal faults, excessive oil refill, or expansion due to high operating temperature. Conversely, a low oil level results from leaks or continuous overload leading to oil loss. A “false high level” may also occur in cold conditions.

Troubleshooting: Check operating temperature and gas relay for gas generation. For low oil levels, locate leaks promptly and add qualified oil if immediate repair isn’t possible.

Abnormal Oil Temperature

Oil temperature anomalies often indicate overload, radiator blockage, or cooling system malfunction.

Troubleshooting: Reduce transformer load, verify fan and pump function, clean radiators, and conduct Dissolved Gas Analysis (DGA) to detect overheating or discharge faults.

Oil Aging and Deterioration

Exposure to oxygen, moisture, and heat leads to oil oxidation, dark color, acidity increase, and insulation loss.

Troubleshooting: Conduct regular tests for breakdown voltage, acidity, and moisture content. Apply vacuum filtration to restore oil performance, or replace oil entirely when degradation is severe.

Abnormal Sounds and Vibrations

Changes in operational sound or vibration often indicate mechanical or electrical faults within the transformer.

Uniform humming signifies normal load changes, while crackling or metallic sounds may reveal partial discharges or loose core clamps. A gurgling sound accompanied by bubbles suggests winding short circuits.

Troubleshooting: Combine sound inspection with DGA results, temperature data, and load variations to pinpoint fault locations. Shut down immediately if internal discharge or loosened parts are confirmed.

Winding Failures

Winding faults are among the most serious transformer failures, often caused by insulation aging, overvoltage, or overheating.

Inter-Turn Short Circuit

Caused by insulation breakdown between winding turns, resulting in localized heating and burning.

Troubleshooting: Detect elevated acetylene (C₂H₂) and hydrogen (H₂) levels through DGA. Check DC resistance imbalance among phases and shut down equipment immediately for factory repair or winding replacement.

Winding Grounding or Phase-to-Phase Short Circuit

Complete insulation breakdown between windings or to the core causes massive short-circuit current, often tripping protection relays.

Troubleshooting: Inspect and repair damaged insulation and replace burned windings. Always verify protection relay action and DGA results post-repair.

Core Failures

The transformer core ensures efficient magnetic flux transfer. Common core faults include multiple grounding points and insulation failure between laminations, both leading to overheating and energy loss.

Troubleshooting: Elevated methane (CH₄) and ethylene (C₂H₄) in DGA suggest overheating. Measure core-ground insulation resistance; if near zero, multiple grounding exists. Disassemble, repair, and restore insulation integrity.

Tapchanger Faults

The tapchanger adjusts transformer output voltage. Faults like poor contact or resistor damage cause increased resistance and local heating.

Troubleshooting: Measure DC resistance at each tap position. High resistance or phase imbalance indicates poor contact. Disassemble, clean, and replace damaged parts, then retest to verify performance.

Bushing Failures

Bushings connect internal windings to external circuits. Contamination, cracks, or seal failure can trigger flashover or insulation breakdown.

Troubleshooting: Clean and inspect surfaces regularly. Measure dielectric loss factor (tanδ) and capacitance. Replace any bushing showing severe cracks or high dielectric loss immediately.

Oil-immersed transformer faults often progress gradually, with early signs visible through changes in oil condition, sound, and temperature. By mastering diagnostic techniques such as DGA analysis, temperature monitoring, and electrical testing, maintenance teams can perform predictive maintenance, prevent catastrophic failures, and ensure long-term reliable operation of power systems.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele