How to Select the Right G10 Fiber Sheet Thickness for Transformer Applications?

In the field of electrical equipment manufacturing, the precise selection of G10 fiber sheets thickness by engineers or technicians is not a random act, but a systematic decision that requires in-depth integration of specific application scenarios and functional requirements. From the perspective of electrical insulation performance, thinner epoxy sheets are favored by electrical equipment designers due to their excellent insulation effect and lightweight advantages. Under conditions of mechanical stress or heavy pressure, thicker epoxy boards can provide stable support and reliable protection for equipment.

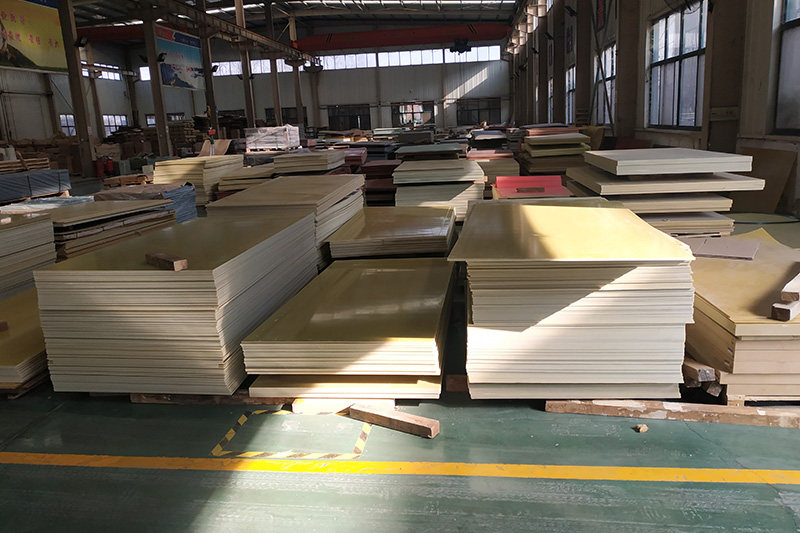

Common thickness of G10 fiber sheet and its application scenarios

1.Thin G10 fiber sheet (0.5mm - 3mm)

This type of epoxy sheet is widely used in the internal insulation structure of electrical equipment produced by electrical equipment manufacturers, gaskets in the manufacturing process of electronic products, and lightweight structural materials due to its light and thin characteristics and excellent insulation performance. It can effectively isolate circuits, eliminate current leakage from the root, and effectively reduce the probability of failure of electrical equipment.

2.Medium-thick G10 fiber sheet (3mm - 10mm)

This board is suitable for scenes with certain requirements for mechanical strength and insulation performance, such as the production and manufacturing process of electrical control boxes, transformers and other equipment. This type of epoxy board provides solid structural support for the equipment while ensuring excellent insulation effect.

3.Thick G10 fiber sheet (10mm - 50mm)

It performs excellently in complex working conditions with large mechanical stress, heavy pressure or impact. This type of sheet is often used by heavy machinery and equipment manufacturers to manufacture heavy machinery and equipment bases, supporting structures, and electrical components with strict requirements for high-strength insulation.

Accurate selection of G10 fiber sheet thickness in transformer applications

1. Clarify the core characteristics of G10 fiber sheet

G10 fiber sheet is made of glass fiber cloth and epoxy resin, and has many excellent properties:

Its high mechanical strength can ensure the stability of the structure;

High temperature resistance reaches above 155℃, adapting to high temperature environment;

Flame retardant properties that meet UL94 V-0 standards improve safety of use;

Volume resistivity is greater than 10^12 Ω・cm, ensuring excellent insulation performance.

In transformer applications, G10 fiber sheet is often used as an insulating partition, support, baffle and lead fixing component.

2. Core factors for G10 thickness selection

· Electrical insulation:

Low voltage transformer (≤1kV): For small dry or control transformers, engineers generally believe that a thickness of 1.5 - 3mm can meet basic insulation requirements. Taking PCB mounted micro transformers as an example, designers often use 1.6mm thick G10 fiber sheet as a partition.

Medium voltage transformer (1kV - 35kV): Technicians need to consider creepage distance and dielectric strength comprehensively, and recommend 3 - 6mm thickness. Especially in key parts such as baffles between high-voltage windings, power frequency withstand voltage tests must be passed.

High voltage transformer (>35kV): Engineers are usually required to customize fiber sheets with a thickness of 8 - 12mm, or even use multi-layer stacking design to meet stringent insulation requirements.

· Mechanical strength:

Support structure (such as core pads, coil brackets): In static load scenarios, 4 - 6mm thickness is sufficient to bear the weight of the transformer itself; in dynamic load environments such as vibration, designers need to use 6 - 10mm thickness and accurately calculate the bending strength, for example, under the condition of a span of 100mm, ensure that a 10mm thick plate has the ability to bear more than 50kg.

Fastener area (bolt fixing area): To prevent cracking, technicians will set the thickness of the epoxy sheet in this area to no less than 5mm, or use local thickening treatment.

· Thermal performance:

In high temperature environments (such as H-class insulation transformers), in order to resist the impact of thermal deformation, engineers need to increase the thickness of the epoxy board by 10% - 20% based on the conventional selection. For example, if the conventional thickness is 3mm, it should be upgraded to 3.5 - 4mm under high temperature conditions.

G10 selection considerations

1. Processing technology points

When the thickness of the epoxy board exceeds 6mm, the processing personnel will find that the delamination problem is easy to occur during the drilling process. At this time, a slow drill bit and a cooling process are required to ensure the processing quality.

2. Cost optimization strategy

In non-critical parts, the company's cost control personnel can use thin plates with reinforcing rib structures, such as replacing 5mm plates with 3mm plates, which can achieve 20% cost savings.

3. Alternative material solutions

If there are ultra-high requirements for strength, engineers can choose G11 materials with better mechanical properties; if cost control is required, procurement personnel will find that FR4 materials are cost-effective, but their temperature resistance is slightly inferior to G10 fiber sheets.

Typical application scenarios and thickness comparison table

|

Application Part |

Recommended Thickness (mm) |

Reason |

|

Low-voltage winding spacer |

1.5~2.5 |

Meets basic insulation, lightweight |

|

High-voltage winding barrier (10kV) |

4~6 |

Prevents partial discharge, enhances mechanical support |

|

Core base insulation block |

5~8 |

Bears core weight, reduces vibration wear |

|

Terminal fixing plate |

3~5 |

Balances insulation and wire clamping force |

|

Outdoor transformer protection plate |

6~10 |

UV-resistant, moisture-proof, requires higher mechanical strength |

Note: For reference only

- more+releated article

- 2026-02-10How to Select the Right G10 Fiber Sheet Thickn

- 2026-02-10G10 vs. Traditional Insulation Materials: What

- 2026-02-10Custom G10 Fiber Sheet Solutions for Transform

- 2026-02-10Why Working with a G11 Epoxy Sheet Manufacture

- 2026-02-10G11 Fiber Sheet in Machinery: Key Uses for Ins

- 2026-02-10G11 Fiber Sheet Uses: High-Temperature Insulat

- 2026-02-10G11 Fiber Sheet Price and Application Compared

- 2026-02-10Step-by-Step Guide: Manufacturing Laminated Wo

- 2026-02-10What is the Role of Electrical Laminated Wood

- 2026-02-10How to detect the quality of electrical lamina