G10 epoxy board in the insulation parts of electrical equipment: key performance and industry applications

In the field of modern industry and electronic engineering, the choice of materials is the core factor that determines the performance and reliability of equipment, especially in the electrical insulation link, its importance is self-evident. Epoxy sheet is highly favored for its excellent insulation performance, and G10 epoxy board, as an upgraded model of epoxy board materials, has become the preferred material for many key application scenarios with its more outstanding electrical insulation properties.

G10 epoxy board is a high-performance material made of specially formulated epoxy resin and glass fiber cloth through a lamination process. It not only fully inherits the basic insulation advantages of epoxy board, but also achieves significant optimization and improvement in multiple key performance dimensions. It has higher dielectric strength and lower dielectric constant, which enables G10 epoxy board to maintain stable and reliable insulation performance in high voltage environment, effectively ensuring the safe operation of electrical systems.

Six core performances of G10 epoxy board

Top flame retardant performance: G10 epoxy board has reached the industry's highest flame retardant grade standard of UL94V0. This means that when encountering a burning situation, the material can quickly self-extinguish in a very short time, minimize the risk of fire, and build a solid protective barrier for the safety of life and property. It is this excellent feature that makes it occupy an important position in the manufacture of high-end electrical insulation parts.

Stable electrical performance: Whether in a dry environment or facing humid working conditions, G10 epoxy board can always maintain excellent electrical performance, and stably play an insulating role in various complex electrical environments, which is an ideal choice for electrical insulation parts.

Excellent mechanical properties: Even in a high temperature environment, G10 epoxy board can still maintain good mechanical properties. It has high hardness and strength, which can effectively resist external stress impact, and ensure the structural integrity of the equipment.

Environmental compliance standards: G10 epoxy sheet strictly follows the EU halogen-free environmental protection standards, meets the development requirements of modern society for green environmental protection. And in the process of production and application, it not only meets performance requirements, but also takes into account eco-friendliness.

Flexible processing performance: G10 epoxy board has good processing adaptability and can be customized to produce products of different colors and specifications according to the diverse needs of customers, fully meeting various personalized application scenarios.

Wide application adaptation: From electronic and electrical insulation parts to high-end transportation tools such as airplanes and trains, to power equipment such as transformers, G10 epoxy board has a wide range of applications.

G10 epoxy sheet industry application

1.High-voltage switchgear

In the manufacture of high-voltage switchgear, G10 epoxy board is often used to make insulating partitions, supports and arc extinguishing chamber components. These key components can effectively ensure that the high-voltage switch can maintain good insulation performance and reliable mechanical stability when operating at high voltage, thereby ensuring the safe and stable operation of the power system.

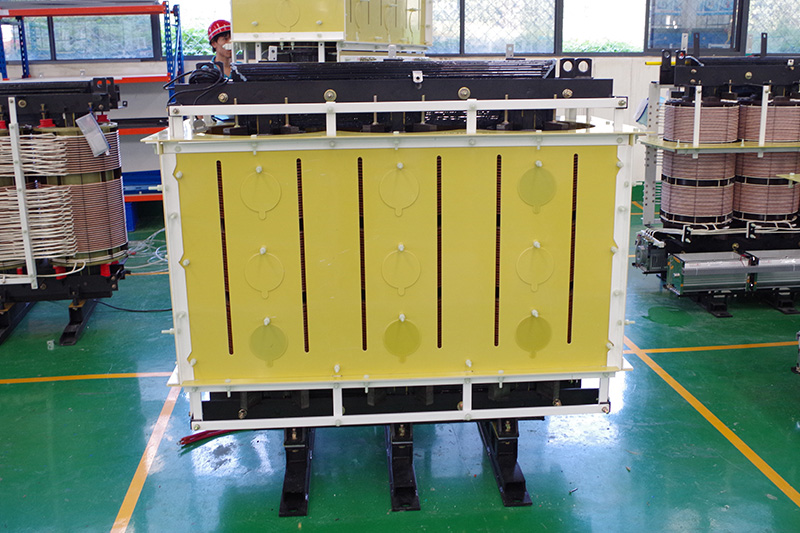

2.Transformer insulation

In the field of transformers, G10 epoxy board can be used to manufacture insulating pads, clamps and winding supports. These components can not only significantly improve the insulation level of the transformer, but also optimize the heat dissipation performance of the equipment, extend the service life of the transformer, and improve the power transmission efficiency.

3.Motor insulation

In the process of motor manufacturing, G10 is used in slot wedges, insulating end plates and winding supports. By enhancing the mechanical strength and insulation reliability of the motor, the operating stability and work efficiency of the motor are effectively improved, and the probability of failure is reduced.

4. Electronic equipment

In the manufacture of printed circuit boards (PCBs), G10 epoxy boards can be used as both substrates and reinforcement materials. With its outstanding performance, it can effectively improve the mechanical strength and heat resistance of PCBs, meeting the development needs of miniaturization and high performance of electronic equipment.

5. New energy equipment

In new energy equipment such as wind turbines and photovoltaic inverters, G10 epoxy sheets are used to manufacture various insulation components. In the face of harsh working environments such as high temperature and high humidity, its excellent performance can ensure the stable operation of new energy equipment and help the development of the clean energy industry.

G10 epoxy boards play an irreplaceable and key role in the field of insulation components of electrical equipment with their excellent mechanical strength, excellent electrical insulation performance, and good flame retardant properties. Although there are certain challenges in terms of cost and processing difficulty, under complex and harsh working conditions such as high pressure, high temperature, and high humidity, G10 epoxy boards can significantly improve the reliability of equipment and extend the service life of equipment. In the long run, they have extremely high cost performance. As electrical equipment continues to develop towards high performance and miniaturization, G10 epoxy board will surely have broader application prospects in the future due to its unique advantages, and continue to provide strong support for the technological progress and development of various industries.

- more+releated article

- 2026-02-10G10 epoxy board in the insulation parts of ele

- 2026-02-10How to Select the Right G10 Fiber Sheet Thickn

- 2026-02-10G10 vs. Traditional Insulation Materials: What

- 2026-02-10Custom G10 Fiber Sheet Solutions for Transform

- 2026-02-10Why Working with a G11 Epoxy Sheet Manufacture

- 2026-02-10G11 Fiber Sheet in Machinery: Key Uses for Ins

- 2026-02-10G11 Fiber Sheet Uses: High-Temperature Insulat

- 2026-02-10G11 Fiber Sheet Price and Application Compared

- 2026-02-10Step-by-Step Guide: Manufacturing Laminated Wo

- 2026-02-10What is the Role of Electrical Laminated Wood