Dry-Type Transformer Model Selection Guide: How to Choose the Best Fit for Your Application

Dry-type transformers come in a wide range of models and specifications, classified according to voltage level, rated capacity, number of phases, and structural design. Choosing the right dry-type transformer model is essential to ensure safe, efficient, and cost-effective power distribution. This article presents a comprehensive guide to help you make informed transformer selections based on real application needs.

Common Classification Methods for Dry-Type Transformers

By Voltage Level:

Dry-type transformers are typically classified into low-voltage (e.g., 0.4kV), medium-voltage (e.g., 10kV), and high-voltage types (e.g., 35kV and above). The voltage level determines the transformer’s insulation design and installation scope.

By Rated Capacity:

Capacities range from 50kVA to several thousand kVA. Choosing the right capacity depends on actual load demand. In general, the larger the capacity, the greater the transformer’s size and weight.

By Number of Phases:

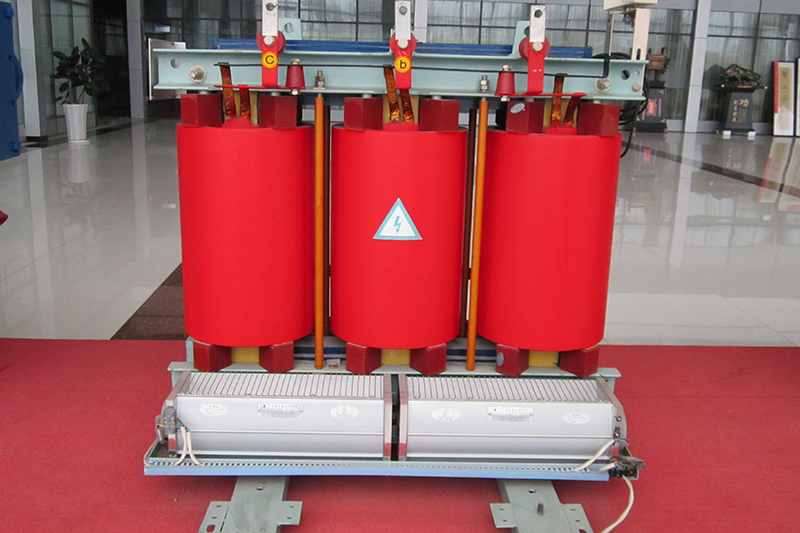

There are single-phase and three-phase dry-type transformers. Single-phase units are suitable for localized or residential loads, while three-phase units serve industrial and commercial power systems.

By Structural Form:

Common types include encapsulated, non-encapsulated, and modular combined structures. Encapsulated models offer excellent resistance to moisture, dust, and corrosion—ideal for harsh environments. Non-encapsulated designs offer efficient heat dissipation, and modular combinations allow for easier transport and installation.

Key Factors to Consider When Choosing a Dry-Type Transformer Model

1. Operating Environment and Load Characteristics

Dry-type transformers are widely used in lighting systems, high-rise buildings, airports, ports, CNC equipment, and more. Their safety and reliability make them ideal for diverse settings. If the system experiences frequent overloads or emergency loads, consider selecting a transformer with forced air cooling to support intermittent overloading.

2. Cooling Method

Cooling is critical to ensure stable operation. Two main cooling methods are available:

Natural Air Cooling (AN): Allows continuous operation at rated capacity, suitable for most standard applications.

Forced Air Cooling (AF): Increases output capacity by up to 50%, supporting temporary overload conditions.

3. Rated Voltage, Current, and Power

Rated Voltage: Indicates the transformer’s maximum continuous operating voltage. It impacts winding design and insulation material.

Rated Current: Refers to the maximum continuous output current. A higher rated current means better adaptability to load fluctuations.

Rated Power (kVA): Defines the maximum output power. It’s recommended to select a transformer with a rated capacity 1.5 to 2 times higher than the connected load to ensure long-term stability.

4. Impedance Voltage

Impedance voltage affects the voltage drop and short-circuit performance of the transformer. A suitable impedance helps maintain power system stability and ensures compatibility with protection devices and load characteristics.

5. Cost vs. Safety

While dry-type transformers are generally more expensive than oil-immersed ones, they are ideal for environments with high safety requirements, such as hospitals, schools, kindergartens, and residential complexes. For cost-sensitive industrial projects with ample ventilation, oil-immersed transformers may offer better thermal performance and lower initial cost.

Application Examples of Dry-Type Transformer Models

Residential Applications:

Low-voltage dry-type transformers like SCB10-1000/0.4 are often used to provide safe, stable electricity to housing communities.

Industrial and Mining Enterprises:

Medium-voltage or high-voltage dry-type transformers such as SCB11-2000/10 or SFZ10-5000/35 are ideal for high-load applications requiring stable large-scale power delivery.

Urban Rail Transit:

For metro systems and railways, encapsulated dry-type transformers like SCBH15-630/10 provide superior moisture and dust protection, ensuring long-term safety in demanding environments.

Optimize Transformer Selection for Safety and Efficiency

Selecting the correct dry-type transformer model involves comprehensive analysis of voltage level, power demand, cooling requirements, and application scenarios. A well-chosen model enhances system performance, reduces energy losses, and minimizes long-term maintenance costs.

We recommend involving professional electrical engineers during the selection process and referring to proven case studies and relevant industry standards. With proper guidance and planning, you can confidently choose a transformer that perfectly fits your technical and economic requirements—achieving both safety and efficiency.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele