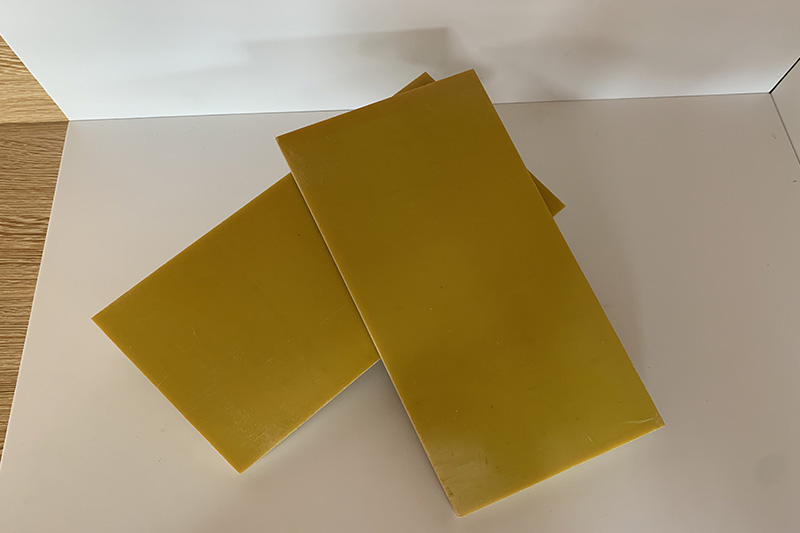

G11 Fiber Sheet Uses: High-Temperature Insulation for Industrial Applications

In the field of industrial high-temperature insulation, G11 fiber sheet stands out with its outstanding performance and becomes an ideal insulation material for F-class and above motors, transformers, high-voltage switches and other equipment. Its core advantages are concentrated in three key aspects: high-temperature stability, insulation performance reliability and environmental adaptability, providing solid guarantees for various industrial applications.

1. High-temperature stability

G11 fiber sheet uses alkali-free glass fiber cloth as the base material, impregnated with epoxy resin and hot-pressed to build an F-class heat-resistant structure with a temperature resistance of 155°C. This unique material composition and manufacturing process give it excellent high-temperature performance:

Continuous high-temperature tolerance: In sharp contrast to ordinary insulating materials, phenolic resin boards soften at 130°C, while G11 fiberglass sheets can work stably for a long time in an environment of 200°C, with a mechanical strength retention rate of more than 90%. This feature makes it the only choice for transformer oil environments, high-voltage switch cabinets and other scenes that are in high-temperature environments for a long time.

Strong thermal shock resistance: During the operation of industrial equipment, frequent start-stop or short-circuit failures will generate instantaneous high temperatures, and the arc temperature can even reach 3000°C. In the face of such extreme conditions, G11 fiber sheet can still maintain structural integrity and effectively avoid equipment failures caused by insulation failure.

2. Insulation performance reliability

Through continuous optimization of material formula and process, G11 fiber sheet has successfully achieved a perfect balance between high temperature performance and insulation performance:

High dielectric strength: The breakdown voltage of G11 fiberglass board is more than 10 times that of air. This feature enables it to effectively isolate high-voltage electric fields and prevent corona discharge and local overheating.

Stable insulation resistance: Under normal conditions, the insulation resistance of G11 fiberglass sheet is ≥1×10¹²Ω. Even in a humid environment with a humidity of 95%, its insulation resistance is still ≥1×10¹⁰Ω, which fully meets the IEC 60243 standard and ensures that the equipment can operate safely under harsh working conditions.

Excellent arc resistance: Arc burning is a common problem when high-voltage equipment is running. G11 fiber sheet can withstand arc burning without carbonization, effectively avoiding insulation layer breakdown, thereby significantly extending the service life of the equipment.

3. Environmental adaptability

With the help of material modification and structural design, G11 fiber sheet has the ability to adapt to different industrial environments:

Chemical corrosion resistance: In chemical media such as transformer oil and SF6 gas, G11 fiber sheet will not react chemically. Its service life exceeds 30 years, which can well meet the insulation requirements of new energy equipment such as wind power converters and photovoltaic inverters.

Excellent flame retardancy: G11 fiber sheet has passed UL94 V-0 certification and has the characteristics of self-extinguishing when away from fire, which greatly reduces the risk of fire and meets the standards of rail transit, data centers and other scenes with extremely strict safety requirements.

Good mechanical strength: The bending strength of G11 fiberglass sheet is ≥300MPa, which is twice that of phenolic board. It can withstand vibration and impact during equipment operation and ensure the stability of the insulation structure under complex working conditions.

4. Typical application scenarios of dry-type transformers

Electric power equipment field

Transformer: As the winding insulation skeleton, G11 fiber sheet can withstand long-term operation at an oil temperature of 105℃-120℃, reducing the failure rate of the transformer by 40%.

High-voltage switchgear: G11 fiber sheet is used for insulation support of disconnectors, circuit breakers and other components, effectively improving the reliability of equipment.

New energy field

Wind power converter: In the wide temperature range of -40℃ to 85℃, G11 fiber sheet can still maintain good insulation performance and adapt to the extreme environment of wind power generation.

Hydrogen fuel cell: As the bipolar plate insulation layer, G11 fiber sheet can not only isolate hydrogen and oxygen, but also withstand the working temperature of 60℃-80℃ of the battery stack.

Rail transportation field

Traction transformer: In the thermal shock environment caused by the frequent start and stop of high-speed rail, the insulation life of G11 fiber sheet exceeds 20 years.

With the rapid development of industrial automation and new energy industries, the performance requirements for high-temperature insulation materials continue to rise. With its comprehensive advantages of high temperature resistance, high insulation and strong adaptability, G11 fiber sheet not only provides reliable protection for traditional power equipment, but also becomes a key support for the new energy and high-end equipment manufacturing fields. Whether it is a harsh extreme environment or a sophisticated electrical system, G11 fiber sheet can protect the safe and efficient operation of industrial production with its stable performance.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele