G10 vs. Traditional Insulation Materials: What Transformer Manufacturers Need to Know

For transformer manufacturers, when selecting insulation materials, a comprehensive understanding of the characteristics, advantages and disadvantages, and applicable scenarios of G10 fiberglass sheet and traditional insulation materials is the key to making the right decision. The following will provide a detailed comparative analysis of these two types of materials to help manufacturers make a more informed choice.

1. Comparison of Characteristics of G10 and Traditional Insulation Materials

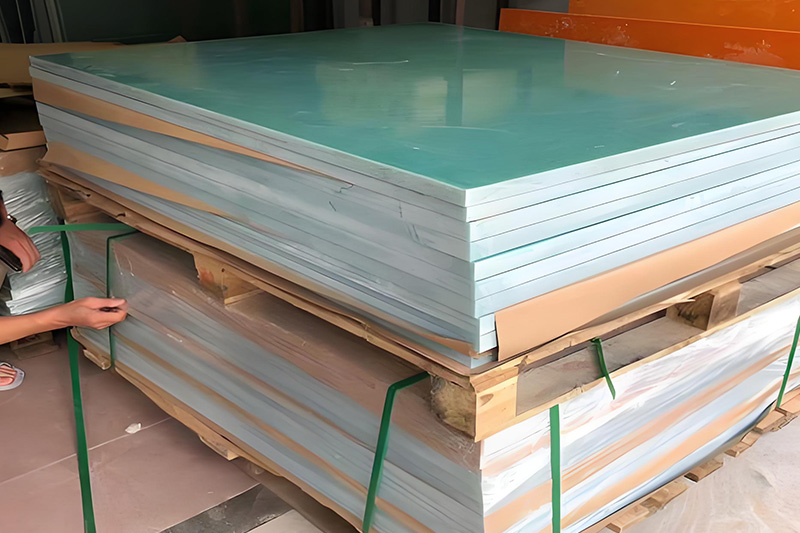

G10 Fiberglass sheet

Composition: It is composed of alkali-free glass fiber and epoxy resin, and has excellent comprehensive performance.

Insulation performance: Excellent electrical insulation performance, can effectively isolate current and prevent electrical breakdown.

Mechanical strength: It has high bending, compressive strength and impact resistance, and can withstand mechanical stress during transformer operation.

Heat resistance: It has stable performance under high temperature environment, high thermal deformation temperature, and low thermal expansion coefficient.

Chemical corrosion resistance: It is resistant to a variety of chemical substances and is suitable for harsh environments.

Processability: It is easy to cut, drill and shape, which meets the needs of transformer manufacturing.

Traditional insulation materials (such as paperboard, wood, mica)

Composition: They are mostly natural or synthetic organic materials, and performance is greatly affected by raw materials and processing technology.

Insulation performance: They are easily affected by environmental factors such as humidity and temperature, poor stability.

Mechanical strength: They are generally low, easy to deform or break under mechanical stress.

Heat resistance: They has limited heat resistance, and are easy to deform or fail at high temperature.

Chemical corrosion resistance: They are sensitive to certain chemicals, prone to corrosion or performance degradation.

Processability: They are difficult to process, and often require special processes or equipment.

2. Comparative Analysis of G10 and Traditional Insulation Materials

G10 Fiberglass Sheet

Advantages: G10 fiberglass sheet offers stable and reliable performance, making it suitable for various complex environments. It is easy to process, which helps improve manufacturing efficiency. Additionally, it is environmentally friendly and sustainable, aligning with the development trends of modern industry.

Disadvantages: The initial procurement cost of G10 fiberglass sheet may be relatively high; however, it delivers significant long-term cost-effectiveness.

Traditional Insulation Materials

Advantages: Traditional insulation materials generally have a lower initial procurement cost and are suitable for applications where performance requirements are not stringent.

Disadvantages: These materials tend to have less stable performance and are more susceptible to environmental influences. Their processing is more difficult, potentially increasing production costs. Moreover, their environmental performance is often poor, and they may pose pollution risks.

3. Application Scenarios for G10 and Traditional Insulation Materials

G10 Fiberglass Sheet

It is well-suited for dry-type transformers operating under harsh environmental conditions, including high voltage, high current, high temperature, high humidity, and high altitude.

Traditional Insulation Materials

Traditional materials are appropriate for applications with low performance demands and relatively stable environmental conditions.

Transformer manufacturers that emphasize performance, reliability, and environmental responsibility should give priority to using G10 fiberglass sheet as their primary insulation material. In special cases, or in projects where cost control is a major concern, manufacturers may consider traditional insulation materials, but only after carefully evaluating their performance stability and environmental impact.

When selecting insulation materials, transformer manufacturers should thoroughly understand the characteristics, pros and cons, and suitable application scenarios of both G10 fiberglass sheets and traditional insulation materials. By conducting a detailed comparative analysis, manufacturers can select the most appropriate insulation material to enhance the performance, reliability, and sustainability of their products. Additionally, they should closely follow the development of new insulation materials to timely optimize product design and manufacturing processes.

- more+releated article

- 2026-02-10G10 vs. Traditional Insulation Materials: What

- 2026-02-10Custom G10 Fiber Sheet Solutions for Transform

- 2026-02-10Why Working with a G11 Epoxy Sheet Manufacture

- 2026-02-10G11 Fiber Sheet in Machinery: Key Uses for Ins

- 2026-02-10G11 Fiber Sheet Uses: High-Temperature Insulat

- 2026-02-10G11 Fiber Sheet Price and Application Compared

- 2026-02-10Step-by-Step Guide: Manufacturing Laminated Wo

- 2026-02-10What is the Role of Electrical Laminated Wood

- 2026-02-10How to detect the quality of electrical lamina

- 2026-02-10Electrical laminated wood supplier price compa