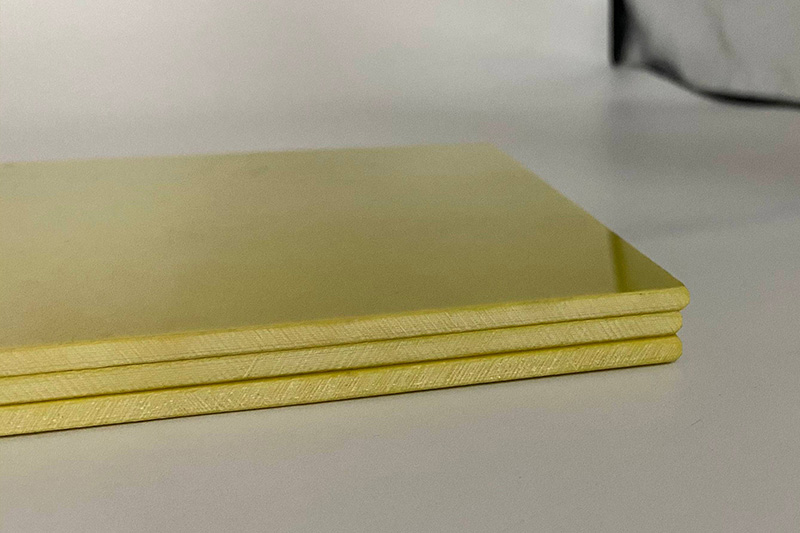

G11 Fiber Sheet Price and Application Compared to G10

In the field of electronic, electrical and mechanical manufacturing, fiberglass sheet is a key basic material, and its performance and cost directly affect product quality and production efficiency. G10 and G11 fiberglass sheets have attracted much attention due to their excellent insulation and mechanical strength, but there are significant differences between the two in performance, price and application scenarios. Understanding these differences will help companies accurately select suitable materials and optimize the balance between cost and performance.

1. G10 and G11 material characteristics

G10 and G11 are both rolled composite products of glass fiber and resin. Among them, "G" stands for glass fiber, and the number reflects the proportion of glass fiber in the material. Both insulation materials are made of imported electronic-grade alkali-free glass fiber cloth fully impregnated with imported epoxy resin, and added with a variety of imported additives such as flame retardants and adhesives, and refined by high-temperature hot pressing process.

2. Performance Comparison: G10 vs. G11

|

Property |

G10 |

G11 |

|

Temperature Resistance |

Standard operating temperature: 130°C |

Long-term operating temperature: 155°C |

|

Mechanical Strength |

High (meets general support needs) |

Higher (excellent flexural & impact resistance) |

|

Dielectric Properties |

Good (suitable for low-frequency applications) |

More stable (better performance in high-frequency applications) |

|

Water Absorption |

Low (suitable for dry environments) |

Extremely low (high reliability in humid conditions) |

3. Price difference and causes between G10 and G11

The price of G11 fiberglass sheet is usually 30%-50% higher than that of G10. The specific differences are reflected in the following aspects:

Material cost difference

G11 uses imported electrical alkali-free glass fiber cloth, which has higher fiber purity and stronger temperature resistance. The cost is about 20%-30% higher than the ordinary glass fiber cloth used in G10.

The epoxy resin formula of G11 has been optimized and high-temperature resistant additives have been added, which further pushes up the cost of raw materials.

Manufacturing process complexity

G11 needs to be hot-pressed at a high temperature of more than 180°C and higher pressure. The increased process complexity leads to an increase in energy consumption of about 15%-20%.

The production yield of G11 is usually lower than that of G10, so the unit cost is further diluted.

Market price reference

G10: As a common standard-grade epoxy fiberglass sheet, the market price of G10 is about 50-150 yuan/㎡. The specific price is greatly affected by thickness and specifications.

G11: Due to its high temperature resistance and better mechanical properties, the market price of G11 is about 80-200 yuan/㎡. Different thickness and suppliers will cause price fluctuations.

4. G10 and G11 application scenarios are differentiated

G10 fiber sheet: conventional electrical insulation and structural support

Core advantages: G10 has become the mainstream choice for insulating structural parts in motors and electrical equipment with its good insulation performance, mechanical strength and processing performance. Its flame retardant grade reaches UL94-V0, which can meet the electrical safety requirements in most dry environments.

Typical applications:

Low-voltage electrical field: It is used as an insulating partition for circuit breakers, switch cabinets, AC contactors and other equipment.

Transformer field: It serves as an insulating support between the transformer core and the coil.

Mechanical structure field: It is used to make wear-resistant parts such as gears, gaskets, and tool handles, relying on its high strength and impact resistance.

New energy field: It is used for lightweight structural parts of wind power and photovoltaic equipment to balance performance and cost.

G11 fiber sheet: Specially designed for high temperature, high humidity and high pressure environment

Core advantages: The temperature resistance level of G11 is increased from 130℃ of G10 to above 155℃, and the water absorption rate is extremely low (water absorption rate ≤0.09% after immersion in water for 24 hours), and it can still maintain stable electrical performance in humid or transformer oil environment.

Typical applications:

High-voltage switchgear: It is used for insulating parts in high-voltage switchgear and high-voltage switches, and can withstand voltage levels above 35kV.

High-temperature industrial environment: It is suitable for insulating structural parts of equipment such as F-class motors and high-temperature fans, and the long-term operating temperature can reach 200℃.

Humid environment: It is suitable for electrical insulation in high-humidity places such as marine engineering, underground tunnels, and chemical workshops.

Transformer oil environment: It is used as an insulating pad for oil-immersed transformers to resist the aging effect of transformer oil.

G10 and G11 fiber sheets have their own advantages and disadvantages. Enterprises should make the best choice between performance and economy based on actual working conditions and cost budgets.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele