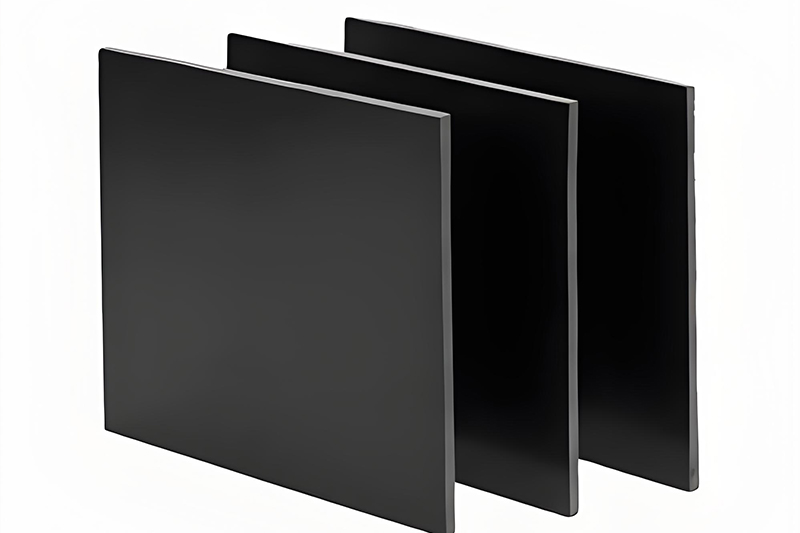

The Role of Black FR4 Anti-static Board in Electronic Manufacturing

In the modern electronic manufacturing industry, electrostatic discharge (ESD) is one of the key factors affecting product quality and yield. Once static electricity accumulates, it may cause semiconductor device breakdown, PCB circuit damage, and even cause safety hazards such as fire. Therefore, the application of antistatic materials has become an indispensable part of the electronic manufacturing process. Black FR4 antistatic board has been widely used in PCB (printed circuit board) manufacturing, SMT (surface mount technology) production line, semiconductor packaging and other fields due to its excellent antistatic performance, stable mechanical strength and good environmental adaptability. This article will explore the characteristics, mechanism of action and key applications of black FR4 antistatic board in electronic manufacturing.

Material properties of black FR4 antistatic board

1. Basic Properties of FR4 Substrate

FR4 is a substrate material composed of glass fiber cloth and epoxy resin. Its characteristics are as follows:

High mechanical strength: The glass fiber reinforced structure gives it excellent bending strength and dimensional stability, which is very suitable for high-precision processing.

High temperature resistance: It can withstand high temperatures above 130°C and can be used in high temperature processes such as reflow soldering and wave soldering.

Excellent electrical insulation: The volume resistivity is high, which can effectively prevent the occurrence of circuit short circuits.

2. Antistatic Modification Technology

Ordinary FR4 itself does not have conductivity, but it can be given antistatic properties by the following methods:

Adding conductive fillers: Such as carbon fiber, graphite, or metal powder, which can control its surface resistance within the range of 10⁶~10⁹Ω, meeting the ESD protection standards.

Antistatic coating: Antistatic agent is applied to the surface to form a conductive layer.

Black coloring: Black can not only reduce light reflection, but also enhance UV resistance, which is suitable for optical detection environments.

The Role of Black FR4 Anti-Static Boards in Electronics Manufacturing

1. Preventing Electrostatic Discharge (ESD)

Electrostatic discharge (ESD) is a major hazard in electronics manufacturing, particularly for sensitive components like MOSFETs and IC chips. Black FR4 anti-static boards help by:

Static Dissipation: Using a conductive surface layer to safely divert static charges to the ground, preventing charge buildup.

ESD Shielding: Reducing interference from external static electricity, protecting high-impedance circuits.

Compliance with ESD Standards: Meeting international standards such as ANSI/ESD S20.20 and IEC 61340, making them suitable for demanding environments like cleanrooms and semiconductor packaging.

2. Providing Stable Mechanical Support

In PCB manufacturing, black FR4 anti-static panels are commonly used for:

Drilling Backing Boards: Preventing burrs and warping during PCB drilling.

SMT Support Plates: Offering a flat, stable surface during SMT placement and reflow soldering, minimizing PCB warpage.

Test Fixtures: Serving as a base for probe testing stations to ensure measurement stability.

3. Optimizing Optical Inspection Environments

The black surface offers several advantages:

Reduced Glare Interference: Enhances inspection accuracy in AOI (Automated Optical Inspection) processes.

Stain Resistance: Compared to green or yellow FR4, black panels show less dirt, reducing cleaning frequency.

4. Chemical Resistance & Environmental Durability

In electronics manufacturing, exposure to flux, cleaning agents, and other chemicals is common. Black FR4 anti-static panels provide:

Solvent Resistance: Withstands corrosion from common cleaning agents like alcohol and isopropyl alcohol.

Moisture Resistance: Low water absorption makes them suitable for high-humidity environments.

Applications of Black FR4 Anti-Static Boards

1. PCB Manufacturing

Drilling Process: Serves as a backing board to reduce drill bit wear and prevent PCB delamination.

Lamination Support: Provides a stable base material during the pressing of multilayer PCBs.

2. SMT Assembly & Reflow Soldering

Carrier Board Application: Supports PCBs through high-temperature reflow ovens, preventing warping.

Anti-Static Work Surface: Prevents component misalignment caused by static attraction in pick-and-place machines.

3. Semiconductor Packaging & Testing

Chip Test Fixtures: Provides an ESD-safe environment for IC testing, preventing electrostatic discharge damage.

Wafer Handling Trays: Minimizes friction-induced static electricity that could harm wafers.

4. Other Electronics Manufacturing Applications

ESD-Safe Repair Mat: Protects sensitive components from ESD damage during electronic repairs.

Insulated Lab Platform: Used for high-precision measurements, eliminating static interference.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele