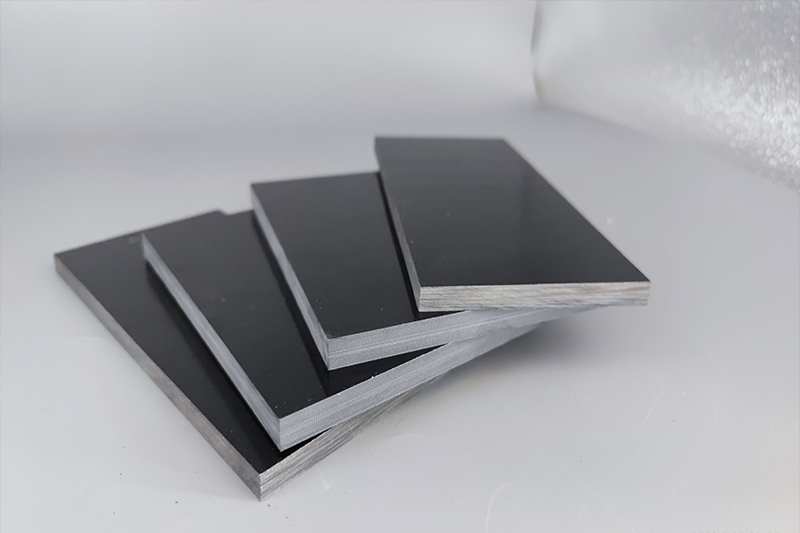

Black FR4 Anti-Static Fiberglass Board: Key Features & Uses

Black FR4 anti-static fiberglass board is a specially modified epoxy fiberglass copper clad (or insulating plate) that adds anti-static function to traditional FR4 materials and adopts a black exterior design. This sheet is widely used in electronic manufacturing, semiconductors, aerospace and other fields, and can effectively prevent electrostatic accumulation (ESD) from causing damage to sensitive electronic components.

Basic composition and structure of black FR4 anti-static fiberglass board

Substrate: It is made of epoxy resin and fiberglass cloth as the substrate. This substrate provides it with high mechanical strength and insulation.

Antistatic layer: Its antistatic layer achieves antistatic effect by adding conductive fillers (such as carbon fiber, carbon powder) or setting up a surface antistatic coating.

Black Appearance: The black appearance of this board is usually made of black resin or dye, which can reduce light reflection and is suitable for optical equipment and high-end electronic instruments.

Main features of black FR4 anti-static fiberglass board

1. Excellent anti-static performance

The surface resistivity of this sheet is usually controlled within the range of 10⁶~10⁹Ω, which can effectively prevent static electricity accumulation and avoid electrostatic discharge (ESD) from damaging sensitive components. It achieves antistatic effects by adding carbon fibers, conductive fillers or surface coatings such as antistatic films.

2. Excellent mechanical strength

The black FR4 anti-static fiberglass board is based on FR4 epoxy fiberglass substrate, with high rigidity, bending and impact resistance, and is suitable for mechanical processing (drilling, cutting, etc.).

3. High temperature resistance and outstanding stability

The sheet has a wide working temperature range (-50℃~130℃), and does not deform at high temperatures, which meets the requirements of electronic equipment for thermal stability.

4. Good electrical insulation

Although the black FR4 anti-static board has anti-static characteristics, it still maintains excellent insulation performance. It has a high volume resistivity and is suitable for circuit board substrates.

5. Strong chemical corrosion resistance

It is resistant to acid, alkali, solvent and other chemical substances and is suitable for harsh environments.

6. Black appearance has specific advantages

Its black appearance is often used to reduce light reflection and is suitable for optical equipment or scenes where aesthetics are required.

Main uses of black FR4 anti-static fiberglass board

1. Semiconductor and electronic manufacturing

Precision test parts: This board can be used for fixtures and jigs for semiconductor wafer and IC packaging testing to prevent static electricity from damaging sensitive devices.

PCB test frame: As a substrate for printed circuit board testing, it can provide insulation support while eliminating static interference.

LCD detector fixture: In the production of liquid crystal panels, it can be used as an antistatic platform for positioning and detection.

2. Electrical insulation and equipment protection

Motor and electrical insulation: Black FR4 antistatic board is used as an insulating structural part of switches, transformers, motors and other equipment. It can replace traditional insulating materials (such as bakelite) to improve heat resistance and mechanical strength.

High-voltage switch insulation board: In high-voltage environments, it can provide reliable insulation and prevent arc breakdown.

Application in transformer oil: This board has excellent oil resistance and can be used in transformer oil for a long time without deformation.

3. Dust-free environment and anti-static engineering

Anti-static workbench: Black FR4 anti-static board as a table or pad can prevent static electricity accumulation during operation.

Optical instruments: In cameras, microscopes and other equipment, it can be used as an anti-static insulation bracket to prevent static electricity from interfering with imaging quality.

4. Other industrial fields

Mold fixture: This board is used as an anti-static substrate for CNC processing and injection molds to improve processing accuracy.

Electronic packaging materials: It can be used to make anti-static trays and turnover boxes to protect the safety of component transportation.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele