How does the diamond density of DDP diamond dot paper affect transformer performance?

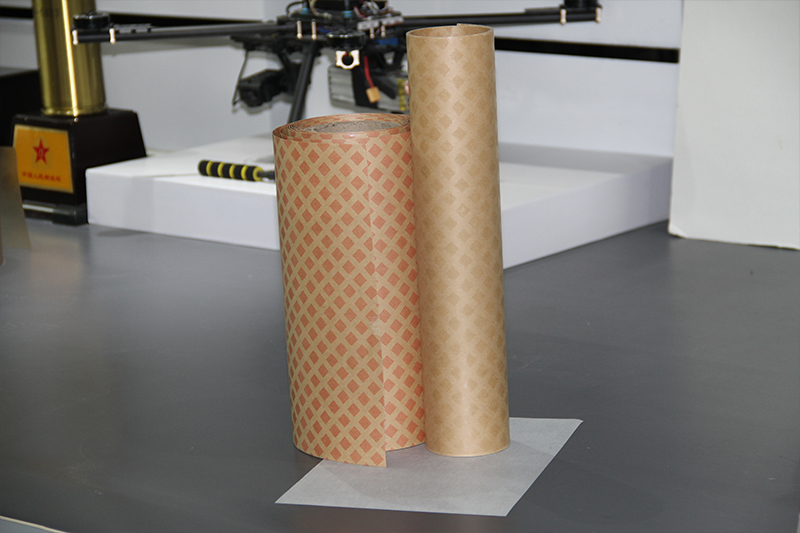

In the insulation system of the transformer, DDP diamond dot paper plays a vital role, and its performance is directly related to the safe and stable operation of the transformer. The diamond density, as a key parameter of DDP diamond dot paper, has a significant impact on its function. The following will analyze in detail the specific impact of the diamond density of DDP on transformer performance.

1. Reduce the risk of partial discharge

The resin coating of the diamond dot paper is distributed in a dotted manner to form a regular diamond gap. This structure provides a clear penetration channel for transformer oil, so that the transformer oil can quickly and evenly penetrate the insulation paper and fill the gap, which not only improves the thermal conductivity of the insulation system, but also removes the residual gas in the insulation material to reduce the electric field distortion.

At the same time, the diamond gap can be used as a discharge channel for the insulating material to release gas during the operation of the transformer to avoid gas accumulation and bubble formation. Bubbles will cause local electric field concentration and lead to partial discharge. When the diamond density is reasonable, it can improve the gas discharge efficiency and significantly reduce the risk.

2. Improve insulation strength

The resin coating of the diamond-shaped paper has a high electrical strength. Its diamond-shaped distribution can guide the electric field to be evenly distributed, avoiding the concentration of the electric field on the surface of the insulating paper or between layers. The more evenly the electric field is distributed, the stronger the voltage resistance of the insulation system is, so it can withstand higher working voltages or overvoltage shocks.

At the same time, the diamond-shaped density reduces the weak points in the insulation layer by optimizing oil penetration and gas discharge, reducing the starting voltage and strength of partial discharge, and extending the insulation life.

3. Enhance mechanical stability

During the drying process of the coil, the resin coating of the diamond-shaped glue paper forms a strong bonding structure with the winding after curing. This structure can effectively prevent the displacement of the layers of the winding due to electromagnetic force during short circuit.

The diamond density directly affects the bonding area:

· Too high density may cause the resin coating to be too thick, and the brittleness will increase after curing;

· Too low density will result in insufficient bonding area and reduced mechanical strength.

Therefore, a reasonable diamond density is the key to balancing bonding strength and flexibility. In addition, the diamond structure of the diamond-shaped glue paper can disperse stress and avoid local stress concentration leading to the rupture of the insulating paper. The composite structure of the resin coating and the insulating paper also improves the overall tear resistance and further enhances the mechanical stability.

4. Improve heat dissipation efficiency and control temperature rise

When the transformer is running, the heat generated by the winding and the core needs to be transferred to the radiator through the insulating oil and the insulating paper. The diamond gap of the diamond-shaped glue paper increases the contact area between the oil and the insulating paper, and provides a channel for the oil flow to promote heat convection. The more fully the oil is soaked, the higher the heat conduction efficiency and the more effective the temperature rise control.

Temperature rise is one of the core factors affecting the life of the transformer. The life of the insulation material is exponentially related to the temperature rise. The diamond density reduces the temperature rise by optimizing heat dissipation, thereby extending the insulation life.

5. Improve manufacturing reliability

Amorphous alloy cores are sensitive to mechanical stress and require a low-stress winding process. The flexibility and bonding strength of the diamond-shaped dispensing paper can meet its requirements, avoiding damage to the core during winding, and its diamond-shaped structure can adapt to the foil winding process, improving the compactness and mechanical strength of the coil.

At the same time, the diamond-shaped density directly affects the coating uniformity and curing effect of the dispensing paper:

· Too high a density may cause uneven flow of the resin coating and defects after curing;

· Too low a density may cause insufficient coating to reduce the bonding strength.

Therefore, a reasonable diamond-shaped density is the key to ensuring the consistency and reliability of transformer manufacturing.

Optimization principle of DDP diamond-shaped density

The diamond-shaped density needs to balance performance and cost, and should be comprehensively selected according to the voltage level, load characteristics and operating environment of the transformer;

The diamond-shaped density should be designed in coordination with parameters such as the thickness of the insulating paper and the width of the oil channel to achieve the optimization of the overall insulation performance;

The final diamond-shaped density needs to be verified by partial discharge test, temperature rise test and mechanical strength test to ensure that it meets the long-term operation requirements of the transformer.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele