What is the manufacturing process for bakelite?

Bakelite, also known as phenolic laminate, is a laminate made of insulating paper or cotton cloth, impregnated with phenolic resin, and then heat-pressed. It offers excellent electrical insulation, mechanical strength, and chemical resistance, making it widely used in electronics, electrical appliances, machinery, and other fields. A thorough understanding of bakelite processing techniques and precautions is crucial for ensuring product quality and improving production efficiency. Below, we will detail the bakelite manufacturing steps.

1. Raw Material Preparation

▶Phenolic Resin:

As the core raw material for bakelite, phenolic resin is produced by the polycondensation of phenols (such as phenol) and aldehydes (such as formaldehyde) under the action of a catalyst. Variations in the ratio of phenols to aldehydes, reaction temperature, pressure, and other conditions result in varying resin properties. Its inherent good adhesion, heat resistance, and chemical stability provide the core strengths of bakelite's performance.

▶Fillers:

Common fillers include wood flour, paper pulp, and glass fiber. Wood flour, due to its widespread availability and low cost, effectively improves the mechanical strength and dimensional stability of bakelite.

Pulp enhances the board's flexibility and impact resistance.

Glass fiber significantly improves the board's heat resistance, mechanical strength, and electrical properties. The specific filler type and dosage should be flexibly adjusted based on the bakelite's performance requirements.

▶Additives:

To optimize bakelite's specific properties, auxiliary materials such as curing agents, lubricants, and colorants are required.

Curing agents promote the cross-linking and curing reaction of phenolic resin, forming a stable three-dimensional network structure. Lubricants prevent adhesion between the material and the mold during processing.

Colorants impart a variety of colors to the bakelite, satisfying the desired appearance in various applications.

2. Pulping or Mixing

▶ Wood Flour and Pulp Fillers:

First, dissolve the phenolic resin in a suitable solvent to create a uniform resin solution.

Then, add the filler in appropriate proportions to the solution. Use specialized mixing equipment to thoroughly mix the filler until it is evenly dispersed throughout the resin solution, forming a slurry with a certain degree of fluidity.

The temperature, speed, and duration of the mixing process must be precisely controlled to ensure uniform and stable slurry quality.

▶ Glass Fiber Fillers:

A prepreg method is typically used. Glass fiber fabric or fiber bundles are immersed in a phenolic resin solution to allow the resin to fully penetrate the fibers. After drying and other treatments, a prepreg with the required resin content and uniform fiber distribution is produced.

The quality of the prepreg directly impacts the final performance of the bakelite board, and key parameters such as resin content and fiber density must be strictly controlled.

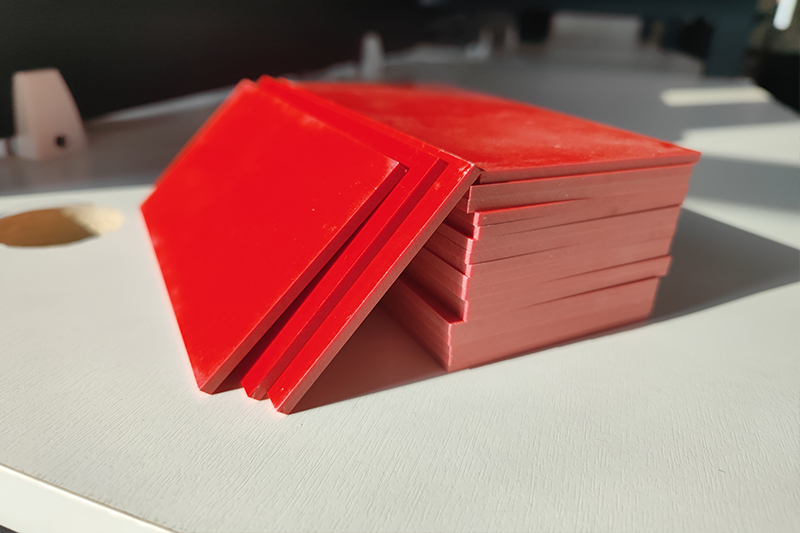

3. Molding

▶Hot Pressing:

This is the most common molding method used in bakelite production. The prepared slurry or prepreg is layered in a mold (consisting of upper and lower mold plates with a specific shape and size) in a predetermined number of layers and thickness. The mold is then placed in a hot press and pressed at a set temperature and pressure. During the hot pressing process, the phenolic resin gradually solidifies, and the filler and resin are tightly bonded, ultimately forming the desired sheet shape.

The hot pressing temperature, pressure, and time are key parameters: The temperature is generally controlled between 150-200°C, the pressure is set between 5-20 MPa depending on the sheet thickness and performance requirements, and the pressing time can range from a few minutes to several dozen minutes. The heating rate and pressure must be precisely controlled during the pressing process to prevent defects such as bubbles and delamination.

▶Compression Molding:

It is suitable for bakelite products with complex shapes and high dimensional accuracy. The pre-treated material is placed in a specially designed mold cavity (with a precise molding cavity and core). Pressure is applied by the press, forcing the material to flow and fill the cavity, while simultaneously curing at high temperatures. This process can produce products with precise dimensions and excellent surface quality, but it also comes at the cost of high mold costs and relatively low production efficiency.

▶Lamination:

Lamination is often used for Bakelite sheets requiring high thickness and strength. Multiple sheets of impregnated prepreg, glue-coated paper, or fabric are neatly stacked and fed into a laminator, where they are pressed under high temperature and high pressure. During the lamination process, the resin cures and firmly bonds the layers, creating a sheet with a specific thickness and properties.

By adjusting the number of layers and the type of material, products with varying properties can be flexibly customized.

4. Post-Processing

▶Heat Treatment:

After hot pressing, bakelite sheets require heat treatment to further enhance their performance. The treatment temperature is typically between 120°C and 180°C, and the duration can range from several hours to dozens of hours. Heat treatment fully cross-links the phenolic resin, significantly enhancing the sheet's hardness, heat resistance, and electrical properties. It also eliminates internal residual stress, reducing the risk of deformation during use.

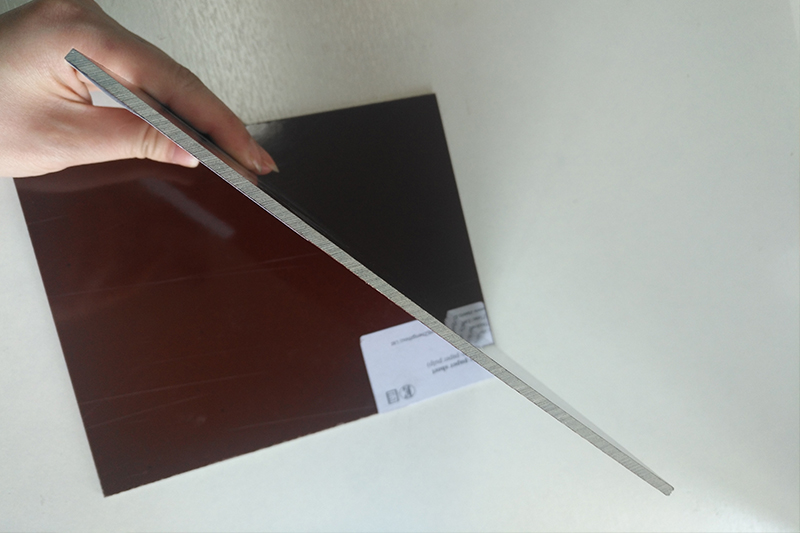

▶Machining:

According to actual needs, bakelite sheets undergo mechanical processing such as cutting, drilling, and milling to produce components of various shapes and sizes to suit different industrial applications. Appropriate tools and parameters must be selected during processing to avoid defects such as chipping and cracking, ensuring quality.

▶Surface Treatment:

To enhance bakelite's corrosion resistance, wear resistance, or decorative properties, surface treatments such as painting and coating can be applied. Painting forms a protective film, improving chemical and wear resistance. Coating imparts special properties such as high hardness and an aesthetically pleasing appearance to the sheet's surface.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri