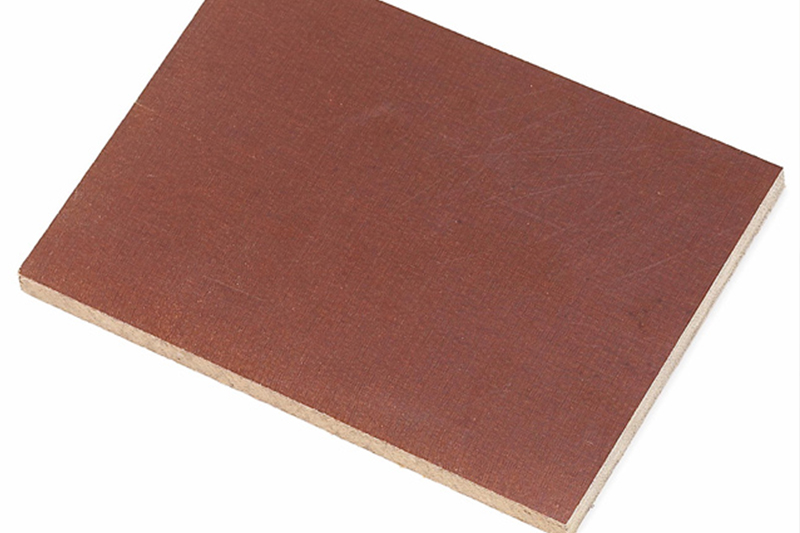

How to Extend the Lifespan of Bakelite? A Complete Guide to Maintenance and Care Tips

Bakelite's excellent insulation properties, high-temperature resistance, and stable mechanical strength make it widely used in electrical equipment insulation and mechanical structural support. However, its service life is directly affected by environmental conditions, operating methods, and maintenance frequency. This article details practical tips for extending the lifespan of Bakelite, covering daily usage specifications, environmental control, cleaning and maintenance, storage requirements, and troubleshooting solutions to help you maximize its performance.

Daily Precautions for Bakelite

1. Avoid Mechanical Damage

During daily handling, avoid scratches caused by sharp objects contacting the surface. Handle with care to prevent edge chipping. For cutting and drilling, use specialized tools such as tungsten carbide drill bits and high-speed steel saw blades. Control the processing speed to minimize cracking caused by friction, overheating, or uneven force distribution.

2. Properly Control Load and Pressure

Bakelite has limited bending resistance. When used as a structural component, a properly designed support structure should be used to distribute the pressure to prevent deformation or fracture caused by long-term overload.

3. Moisture-Proof Measures

Although bakelite has basic moisture-proof properties, prolonged exposure to high humidity can degrade its insulation and soften the material. It is recommended that it be stored or used in an environment with a relative humidity of 70% or less. In humid areas, apply moisture-proofing agents or install dehumidification equipment.

Environmental Adaptability Maintenance

1. Key Points of Temperature Management

The recommended long-term operating temperature for ordinary bakelite is ≤120°C. High-temperature-resistant models can withstand temperatures above 150°C. Please refer to product specifications for details. Avoid sudden changes in temperature during use to prevent internal cracking. Install a heat sink or ventilation system to reduce the temperature in high-temperature environments.

2. Chemical Corrosion Protection

Bakelite is sensitive to strong acids, bases, and organic solvents, and is susceptible to surface corrosion and material swelling upon contact. Clean gently with a neutral detergent with a pH of 6-8 to avoid chemical damage.

3. UV Protection (Outdoor Applications)

Extended exposure to sunlight can cause bakelite used outdoors to age, become brittle, and darken. Applying a UV-resistant coating, installing a sunshade, or using specialized bakelite with UV-resistant additives may be necessary to slow down aging.

Bakelite Cleaning and Maintenance Tips

1. Regular Cleaning Procedure

Weekly or monthly, wipe the surface with a soft cloth such as a microfiber cloth and a neutral detergent or 75% or less alcohol to remove oil, dirt, and dust. Avoid using hard tools such as steel wool and stiff brushes. For stubborn stains, spot-clean with 5% or less soapy water. Dry immediately to prevent residual moisture.

2. Surface Protection

Apply specialized insulating oil or automotive wax every 3-6 months to enhance surface sealing and wear resistance. Highly used sliding parts (such as mechanical guide rails) can be coated with silicone grease to reduce friction and wear.

3. Regular Inspection and Minor Troubleshooting

Perform a comprehensive monthly inspection, focusing on cracks, delamination, deformation, and edge burrs. Fill and repair small cracks with epoxy glue, and smooth edge burrs with 400 grit or higher sandpaper to prevent further damage.

Bakelite Storage Specifications

1. Store Flat to Prevent Deformation

Large-sized bakelite boards longer than 1 meter should be stored flat on horizontal drying racks to avoid bending caused by vertical placement or tilting. When stacking, place soft materials such as foam paper or kraft paper between boards to prevent scratches.

2. Store in a dark and ventilated environment

Warehouses should be kept away from direct sunlight and heat sources such as radiators and ovens. The ambient temperature should be maintained between 10-30°C to prevent high temperatures from accelerating material aging.

Bakelite Lifespan Warning Signs

Bakelite board performance has severely degraded and should be replaced if the following conditions occur:

Severe surface powdering, large cracks, or delamination;

Insulation resistance measured by a megohmmeter is less than 0.5 MΩ;

The warpage is greater than 5mm/m and cannot be restored by pressure.

Proper maintenance can significantly extend the lifespan of bakelite boards, typically lasting 5-10 years or even longer. The key is to develop a targeted maintenance plan based on actual application environments such as high temperature, humidity, and outdoor environments, including regular cleaning, inspection, and maintenance. It is recommended to establish maintenance files for key bakelite components in high-value equipment to track inspection results and maintenance measures to ensure safe and stable operation of the equipment.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele