What Are the Disadvantages of Using Cast Resin Transformers?

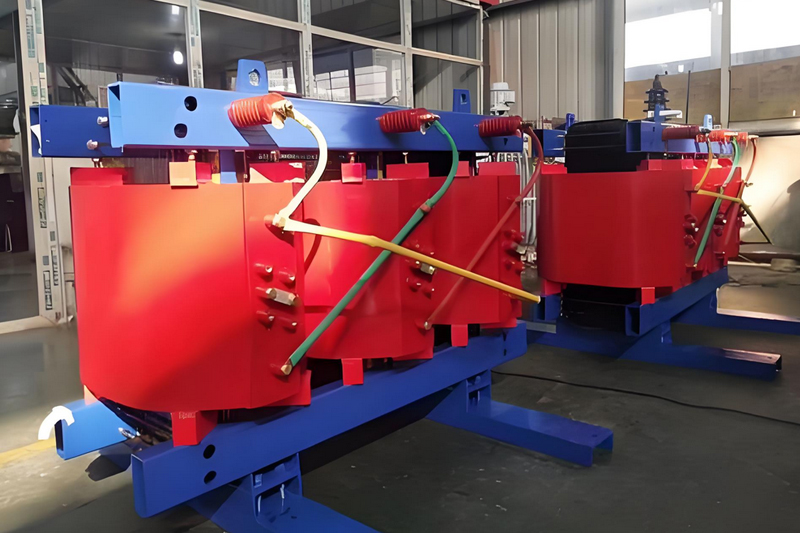

Cast resin transformers, a type of dry-type transformer, are known for their excellent fire resistance, environmental performance, and low maintenance needs. They are widely used in commercial buildings, hospitals, schools, factories, and offshore wind power projects. However, compared to traditional oil-immersed transformers, cast resin transformers have several disadvantages in terms of technical features, operating costs, and long-term usability.

1. Relatively Weak Heat Dissipation

This is the most critical shortcoming of cast resin transformers.

Low thermal conductivity: Resin has much lower thermal conductivity compared to transformer oil. In oil-immersed transformers, oil transfers winding heat efficiently to radiators and dissipates it through circulation and convection. Resin, as a solid, only relies on its limited thermal conductivity, transferring heat slowly to the casing. Heat then dissipates through cooling ribs, reducing efficiency.

Weak short-term overload capacity: Because of poor heat dissipation, cast resin transformers typically have lower overload tolerance. For applications with frequent load fluctuations, larger-capacity units must be installed, which increases investment costs.

Strict design requirements: Manufacturers must carefully design rib layout and casing dimensions. Any flaws in design may lead to high operating temperatures, reducing insulation life.

2. High Initial Investment Cost

Expensive raw materials: Epoxy resin, quartz powder, and fillers, plus specialized casting molds, are significantly more costly than oil and steel plates used in oil-immersed transformers.

Complex manufacturing process: Vacuum casting and high-temperature curing require advanced equipment and precise control of process parameters such as vacuum levels, resin ratios, and curing profiles. This makes the production of dry-type transformers more expensive.

As a result, cast resin transformers of the same capacity generally cost more than oil-immersed transformers.

3. Large Size and Heavy Weight

Due to low heat dissipation, larger casing surfaces with multiple cooling ribs are required, making cast resin transformers bulkier. The density of resin and fillers also adds weight, increasing demands on transportation, installation, and foundation load-bearing.

4. Difficult to Repair

The monolithic encapsulation design improves reliability but makes repair nearly impossible. If internal faults occur (e.g., winding shorts or insulation breakdown), the transformer often needs to be returned to the factory for resin removal, repair, and re-casting—a process that is costly and complex. In many cases, replacement is more economical.

By contrast, oil-immersed transformers, though requiring professional repairs, allow more feasible on-site restoration.

5. Strict Process and Material Requirements

The vacuum casting process must completely eliminate air bubbles. Even small process defects—such as poor vacuum, incorrect mixing ratios, or flawed curing cycles—may create internal voids or cracks. Over time, these defects can lead to partial discharges, insulation failure, and breakdown.

Thus, the quality of cast resin transformers depends heavily on the manufacturer’s process capability and strict quality control.

6. Higher Operating Noise

The cured rigid windings have higher natural frequencies, causing stronger vibration transmission under alternating magnetic fields. This makes cast resin transformers noisier than oil-immersed transformers of the same rating. In noise-sensitive environments like hospitals or residential areas, damping pads or soundproof enclosures are required, which further increases costs.

The disadvantages of cast resin transformers mainly involve cost, heat dissipation, repair difficulties, and higher noise levels. However, as a type of dry-type transformer, their superior fire safety and environmental benefits often make them the preferred choice in applications with strict safety and environmental requirements.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer