What are the Main Applications of FR4 Epoxy Board Machined Parts?

FR4 epoxy board is a high-performance electronic insulating material, widely used in the electronics field and industrial manufacturing. Thanks to its excellent mechanical strength, high-temperature resistance, electrical insulation, and chemical corrosion resistance, it has become an ideal material for many critical applications. This article will provide an in-depth analysis of the main application scenarios of FR4 epoxy board machined parts, helping you fully understand their diverse uses.

What is FR4 Epoxy Board?

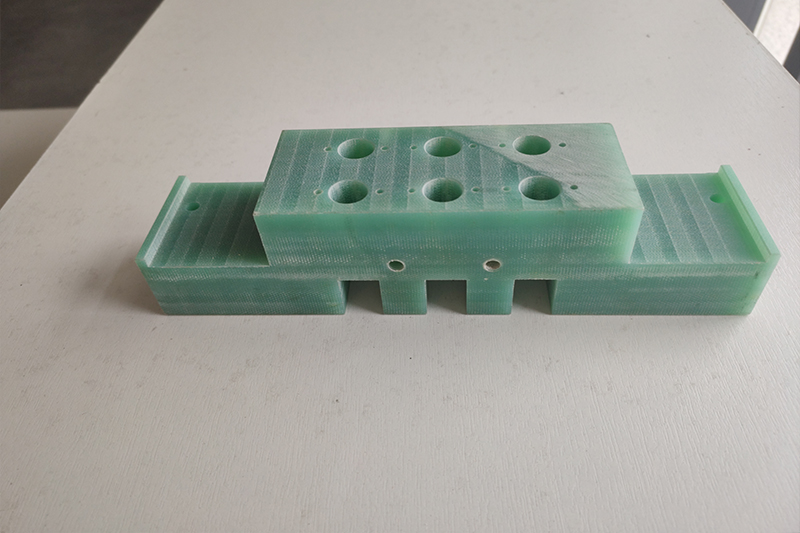

FR4 epoxy board is a composite material made by impregnating glass fiber fabric with epoxy resin and then curing it under heat and pressure. “FR” stands for “Flame Retardant,” meeting the UL94V-0 flame-retardant standard. This material offers excellent dimensional stability, machinability, and arc resistance. It can be machined into various precision components using CNC processing, drilling, milling, and other techniques.

Main Features of FR4 Epoxy Board Machined Parts

High Mechanical Strength: FR4 machined parts are composed of epoxy resin reinforced with glass fiber, providing outstanding strength and hardness, capable of withstanding significant pressure and load.

Excellent Electrical Insulation: FR4 parts have stable insulation performance and can operate long-term in high-voltage and complex electrical environments. They are widely used for electrical equipment insulation and PCB support.

Good Heat Resistance: FR4 parts have a high thermal rating, typically withstand continuous working temperatures above 130°C, and can tolerate even higher temperatures for short periods.

Superior Machinability: FR4 parts can be shaped using cutting, drilling, milling, laser processing, and other methods, which can meet customized project requirements.

Common Application Scenarios of FR4 Epoxy Board Machined Parts

1. Electronics and Electrical Industry

PCB support components, insulating gaskets, and conductive isolation parts

Supporting and fastening parts for relays, switches, terminals, and transformers

Various insulating components used in motors and high-frequency equipment

2. Mechanical Manufacturing and Automation Equipment

High-precision mechanical positioning parts, transmission gears, and sliders

Wear-resistant insulating components used in automated production lines

3. Energy and Power Equipment

Insulating support parts for distribution cabinets, switchgear, transformers, and busbars

Insulation components and protective plates for high-voltage electrical equipment

How to Choose the Right FR4 Epoxy Board Machined Parts?

When selecting FR4 machined components, the following factors should be considered:

Thickness specifications: Commonly 0.5 mm–50 mm. And special thicknesses can be customized.

Copper foil type: Options include single-sided, double-sided, or copper-free.

Flame-retardant rating: Preferably compliant with the UL94V-0 standard.

Dielectric constant and dissipation factor: Match different electrical application scenarios.

Mechanical strength: Select according to load-bearing and force requirements.

Operating temperature range: High-temperature environments require higher thermal-resistant grades.

Special machining requirements: Such as precise hole positioning or specific tolerance control.

Future Development Trends

With the rapid advancement of technologies such as 5G communications, the Internet of Things, and new energy vehicles, the market demand for FR4 epoxy board machined parts will continue to rise. In the future, their applications will mainly focus on the following directions:

Optimizing performance for high-frequency and high-speed scenarios

Developing product grades with higher heat-resistance levels

Promoting the use of environmentally friendly halogen-free FR4 materials

Advancing precision and miniaturized machining technologies

With excellent mechanical strength, electrical insulation, and heat resistance, FR4 epoxy board machined parts have become indispensable materials in industries such as electronics and electrical engineering, mechanical manufacturing, and energy and power systems. Whether used as support components, insulation pieces, or structural parts, they can deliver stable and reliable performance.

When selecting FR4 components, enterprises need to consider the specific application environment, working load, and temperature requirements to customize the most suitable machined parts and maximize the advantages of FR4 material.

If you are looking for reliable FR4 epoxy board machining solutions, it is recommended to choose a professional supplier with extensive experience, advanced processing equipment, and a robust quality management system to ensure the delivery of high-quality machining parts that meet your application needs.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer