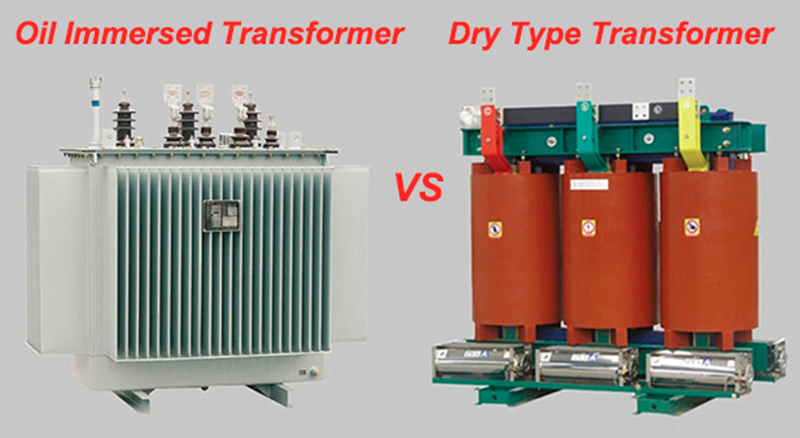

Dry-Type vs. Oil-Immersed Transformers: A Comprehensive Comparison of Advantages

In power transmission and distribution systems, transformers play a vital role. Among them, dry-type transformers and oil-immersed transformers are two common types. And each has its own unique advantages and is suitable for different application scenarios. This article will deeply analyze the advantages of dry-type transformers and oil-immersed transformers, and provide you with a clear comparative analysis.

Significant advantages of dry-type transformers

Excellent safety

Dry-type transformers abandon traditional transformer oil and use air or solid insulation materials as insulating media. This design eliminates the fire and explosion hazards caused by oil filling from the root. In crowded places, such as high-rise buildings towering into the sky, substations buried deep underground, bustling commercial centers, airports and stations with constant flow of people, the safety advantages of dry-type transformers are fully reflected. Even if a fault occurs, it will not cause serious safety accidents due to oil leakage and combustion like oil-immersed transformers, building a solid safety barrier for the stable operation of the power system.

Outstanding environmental performance

During the operation of dry-type transformers, there will be no oil pollution problems, which is very friendly to the ecological environment. Since no transformer oil is required, there is no need to set up special oil storage and treatment facilities, which greatly reduces the risk of oil pollution. Moreover, whether it is the production link, the use stage, or the scrapping process, the impact of dry-type transformers on the environment is relatively small. This is highly consistent with the pursuit of green environmental protection in modern society.

Convenient installation and maintenance

Dry-type transformers are characterized by small size and light weight. During installation, there is no need to consider complex oil treatment systems and cumbersome fire and explosion prevention measures, which can greatly save installation space and costs. Its structural design is simple, and maintenance work is relatively easy. There is no need to regularly test, filter and replace oil, which significantly reduces maintenance costs and difficulties. In addition, the noise generated by dry-type transformers during operation is extremely low, and will not cause obvious interference to the surrounding environment.

Unique advantages of oil-immersed transformers

Excellent insulation and heat dissipation performance

Oil-immersed transformers use transformer oil as an insulation and cooling medium. Transformer oil has extremely high insulation strength, can effectively isolate high-voltage and low-voltage parts, and effectively prevent leakage and short-circuit accidents. At the same time, the circulation of oil can quickly take away the heat generated by the transformer during operation, ensuring that the transformer always remains within the normal operating temperature range. Compared with dry-type transformers, oil-immersed transformers have higher heat dissipation efficiency and can operate stably even under high load and high temperature environments. Therefore, they are very suitable for large-capacity and high-voltage power systems.

Lower cost advantage

The manufacturing cost of oil-immersed transformers is relatively low, thanks to their mature raw materials and production processes. Under the large-scale production model, production costs can be effectively controlled. In addition, although oil-immersed transformers require regular oil inspection and maintenance, the overall operation and maintenance costs still have certain advantages. This makes oil-immersed transformers popular in projects that are more sensitive to cost.

Mature and reliable technical system

Oil-immersed transformers have a long history of development, are relatively mature in technology, and have accumulated rich experience in design and manufacturing. Its structure and performance have been tested in practice for a long time, and its reliability and stability are extremely high. For some places with strict requirements on the stability of the power system, such as large power plants and substations, oil-immersed transformers are still the best choice.

Powerful large-capacity characteristics

Oil-immersed transformers can achieve large capacity and can fully meet the needs of large-scale power systems. In large industrial enterprises and power hubs, a large amount of electric energy needs to be transmitted and distributed, and the large-capacity advantages of oil-immersed transformers can be fully utilized to ensure the stable operation of the power system.

Comprehensive comparison and application scenario analysis

Applicable scenario differences

Dry-type transformers are more suitable for places with high fire protection and environmental protection requirements, as well as limited space environments such as indoors and underground, due to their excellent safety and environmental protection performance. Oil-immersed transformers are more suitable for large-capacity, high-voltage power systems, as well as outdoor, open environments with relatively low fire protection requirements.

Complementary performance

In practical applications, dry-type transformers and oil-immersed transformers are not mutually exclusive, but can complement each other. For example, in urban substations, dry-type transformers can be used to meet indoor installation and fire protection requirements; in external substations of large industrial enterprises, oil-immersed transformers can be used to achieve large-capacity power transmission and distribution. Through reasonable use, the advantages of the two transformers can be fully utilized to improve the overall performance of the power system.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele