Advantages and Disadvantages of GPO-3 Sheets in Electrical Applications

In the manufacturing and operation of electrical equipment, the performance of insulation materials directly affects the safety, stability, and service life of the equipment. As a commonly used electrical insulation material, GPO-3 sheets offer unique advantages in electrical applications, while also having certain limitations.

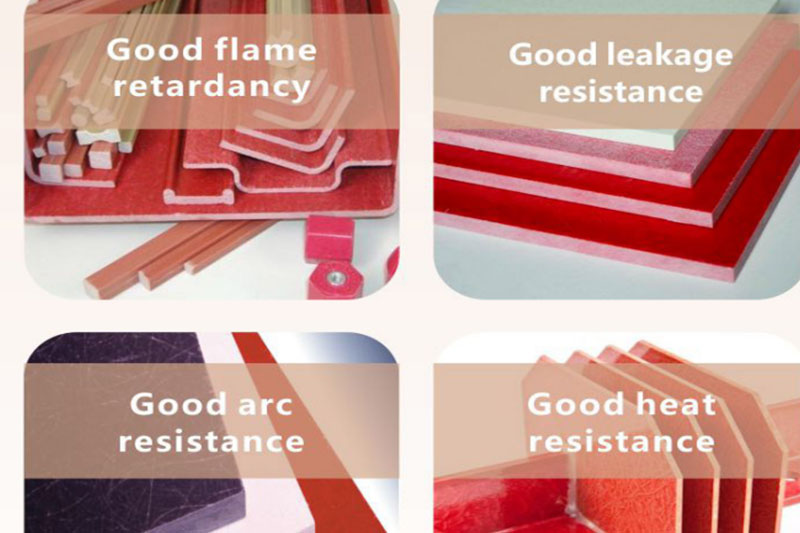

Advantages of GPO-3 Sheets in Electrical Applications

1. Excellent Electrical Insulation Performance

GPO-3 sheets feature extremely high insulation resistance and voltage withstand capability. Even in harsh environments such as high humidity or pollution, they can maintain excellent insulating properties. Their high dielectric strength effectively prevents electrical breakdown, making them an ideal choice for insulation components in high-voltage equipment such as circuit breakers, disconnect switches, and transformers. This ensures long-term stable operation of the equipment.

2. Outstanding Arc Resistance and Tracking Resistance

Electric arcs and tracking are common causes of failure in high-voltage equipment. Thanks to their exceptional arc resistance, GPO-3 sheets can maintain structural integrity even under prolonged exposure to arcing, preventing issues like carbonization and surface erosion. In addition, their excellent tracking resistance makes them suitable for use in devices such as contactors and relays, which involve frequent switching or spark generation, significantly reducing the risk of equipment failure.

3. Good Mechanical Strength and Processability

GPO-3 sheets possess high rigidity, impact resistance, and flexural strength, enabling them to withstand significant mechanical stress. They are well-suited for manufacturing insulation components that require structural support. Additionally, GPO-3 sheets offer excellent workability and can be shaped into complex parts tailored to various electrical equipment needs using standard processing methods such as cutting, drilling, and milling.

4. Excellent Flame Retardant Properties

Fire safety is a critical consideration in electrical equipment. GPO-3 sheets are flame-retardant materials that do not emit large amounts of smoke or toxic gases when burning, meeting stringent fire safety standards. As a result, they are widely used in fields with high fire protection requirements, such as railway systems, marine electrical systems, and data centers.

5. Stable High-Temperature Resistance

GPO-3 sheets have a high thermal rating and can operate stably under high temperatures for extended periods without significant deformation or performance degradation. This characteristic makes them especially valuable in heat-generating electrical equipment like motors and transformers, ensuring the reliability of insulation systems under elevated temperature conditions.

Disadvantages of GPO-3 Sheets

1. Higher Cost

Compared to common insulation materials such as phenolic and epoxy boards, GPO-3 sheets involve a more complex manufacturing process and use relatively expensive raw materials. This results in a higher market price. The elevated cost increases the overall manufacturing expenses of electrical equipment and limits GPO-3's adoption in cost-sensitive applications.

2. Higher Density and Heavier Weight

GPO-3 sheets have a greater density than some plastic-based insulation materials. In industries like aerospace and new energy vehicles, where lightweight design is critical, the heavier GPO-3 sheets may not be the optimal choice. Their increased weight can complicate equipment installation and transportation, and may also impact overall equipment performance.

3. Water Absorption Affects Long-Term Insulation Performance

While GPO-3 sheets exhibit excellent insulation properties in dry environments, their performance may degrade to some extent under prolonged exposure to moisture or submersion. Therefore, when used in extremely humid or underwater electrical systems, additional protective measures are necessary to ensure consistent insulation performance.

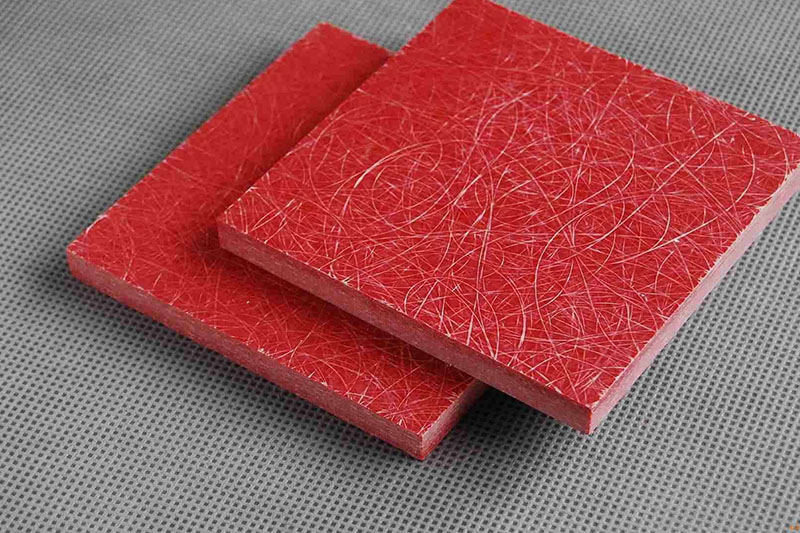

4. Limited Color and Appearance Options

GPO-3 sheets are typically available in red, white, or brown. If special colors are required, customization is necessary. This limitation in color and appearance makes GPO-3 less suitable for applications where aesthetics are a key consideration.

5. Relatively Brittle with Limited Crack Resistance

Although GPO-3 sheets offer high mechanical strength, they lack sufficient toughness. Under strong impact or vibration, micro-cracks may develop. Therefore, in applications where high impact resistance is essential, GPO-3 sheets are often used in combination with other materials to compensate for their limited crack resistance.

GPO-3 sheets play a crucial role in high-voltage electrical equipment, switchgear, and motor insulation, thanks to their excellent electrical insulation, arc resistance, flame retardancy, and good mechanical strength. They are a preferred choice in applications with strict insulation and fire safety requirements. However, the relatively high cost, greater density, water absorption, and limitations in color, appearance, and crack resistance can pose challenges in applications that demand low cost, lightweight structures, enhanced aesthetics, or high impact resistance.

In actual material selection for electrical equipment, it is essential to thoroughly evaluate the advantages and disadvantages of GPO-3 sheets based on specific application requirements, performance standards, and budget constraints.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele