High-Performance GPO-3 Sheets for Electrical Insulation – Flame Retardant & Durable

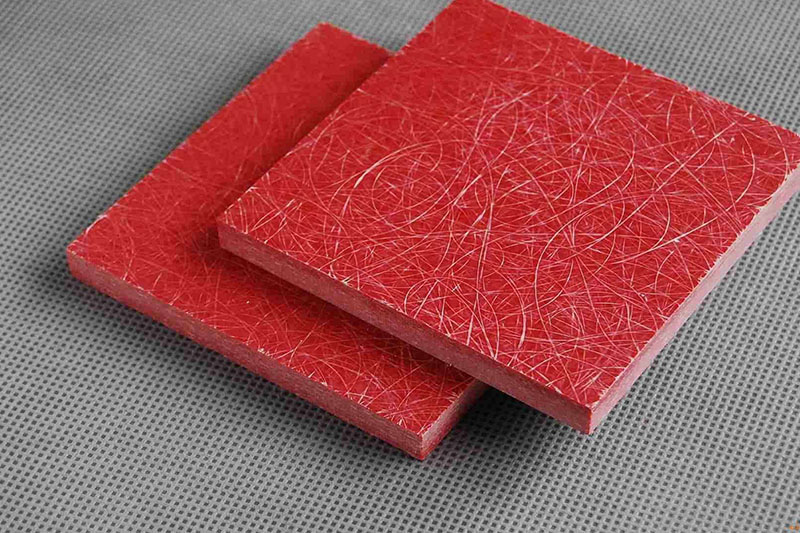

In the electrical and power industries, the performance of insulation materials directly impacts the safety and reliability of equipment. GPO-3 sheets, also known as UPGM-203, have become an indispensable material in this field due to their outstanding all-around properties. Manufactured through a hot-pressing process, GPO-3 is made from alkali-free glass fiber mats impregnated with unsaturated polyester resin paste and specific additives. This rigid sheet insulation material offers exceptional flame retardancy, mechanical strength, electrical insulation, and environmental resistance, granting it unmatched value in demanding applications.

Fundamental Properties and Advantages of GPO-3 Sheets

1. Flame Retardancy

GPO-3 is formulated with a halogen-free composition, meaning it does not release toxic gases when ignited—perfectly aligning with modern environmental standards. It meets the stringent UL 94 V-0 flammability classification in the United States. In vertical burn tests, GPO-3 self-extinguishes within 10 seconds without producing flaming drips that could ignite cotton beneath it, demonstrating highly reliable flame-retardant behavior.

Additionally, its low smoke and low toxicity characteristics help minimize harm caused by toxic fumes in the event of a fire, buying critical escape time for occupants. These features make GPO-3 an ideal material for electrical equipment used in high-rise buildings, subways, and other densely populated areas where fire safety is a top concern.

2. Mechanical Strength

Composed primarily of high-strength glass fibers, GPO-3 exhibits excellent mechanical performance. Its shore hardness, tensile strength, and compressive strength are all at high levels, delivering superior impact resistance and making it difficult to crack or fracture. In real-world applications, GPO-3 can be bent to a diameter of 19mm without breaking, showcasing its impressive combination of flexibility and toughness.

This makes it especially suitable for environments subject to frequent vibrations or mechanical stresses, such as in motor armature components and removable electrical covers.

3. Electrical Insulation Performance

GPO-3 exhibits excellent adaptability when it comes to electrical insulation. Even in high-humidity environments, it maintains stable electrical properties. It offers strong resistance to tracking, with a Comparative Tracking Index (CTI) exceeding 600V, and boasts high surface and volume resistivity. These features ensure safe equipment operation in harsh conditions, effectively preventing leakage current and arc discharge, thereby extending the service life of the equipment. For instance, in outdoor switchgear and transformers, GPO-3 helps ensure reliable and safe operation.

Processing and Application Advantages of GPO-3 Sheets

1. Machinability

GPO-3 offers excellent machinability and can be processed using a variety of techniques including lathe turning, punching, trimming, drilling, sandblasting, grinding, sawing, and milling to create various components. Its high compatibility with automated processing ensures product consistency and meets diverse manufacturing demands. During assembly, GPO-3 components can be easily fastened using adhesives, metal screws, or rivets, making the installation process simple and efficient.

2. Application Fields

GPO-3 is widely used across multiple applications:

In circuit breakers, it serves as safety barriers, arc shields, interphase spacers, and insulation pads for both molded case and frame-type breakers.

In motors, it is used for armature components, removable covers, stator slot wedges, insulating pads, and thin spacers.

In switchgear systems, it is applied to partition systems including the front, rear, top, bottom, and interphase barriers.

Additionally, GPO-3 is ideal for insulation panels in switchgears, arc extinguishing covers, arc tubes, arc plates, as well as for AC contactors, explosion-proof electrical devices, and various low-voltage electrical insulation barriers.

Comparative Analysis of GPO-3 and Other Materials

Compared with SMC insulation boards, GPO-3 demonstrates significant advantages in flame retardancy, mechanical strength, and electrical insulation performance. SMC boards are primarily composed of special SMC yarns, unsaturated resins, and various fillers, but they tend to have a lower elastic modulus, making them more prone to deformation. Additionally, SMC materials exhibit weaker rigidity and poorer machinability, with lower insulation resistance.

In contrast, GPO-3 has a high elastic modulus, excellent rigidity, and superior machining performance. It does not suffer from issues like delamination or splitting during processing. GPO-3 also possesses higher surface and volume resistivity, which contributes to its outstanding insulation capabilities.

Due to its superior properties, GPO-3 is better suited for applications requiring high levels of flame retardancy, mechanical strength, and electrical insulation, such as in high-voltage switchgear, transformers, and other critical power equipment.

On the other hand, SMC insulation boards are more appropriate for cost-sensitive applications where performance demands are relatively lower—such as electrical enclosures, switchgears, and general-purpose housings.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer