Electrical insulation fr4 garolite g10 sheet material

Do you know that electrical insulation fr4 garolite g10 sheet material can be used for carrier of lapping machine?

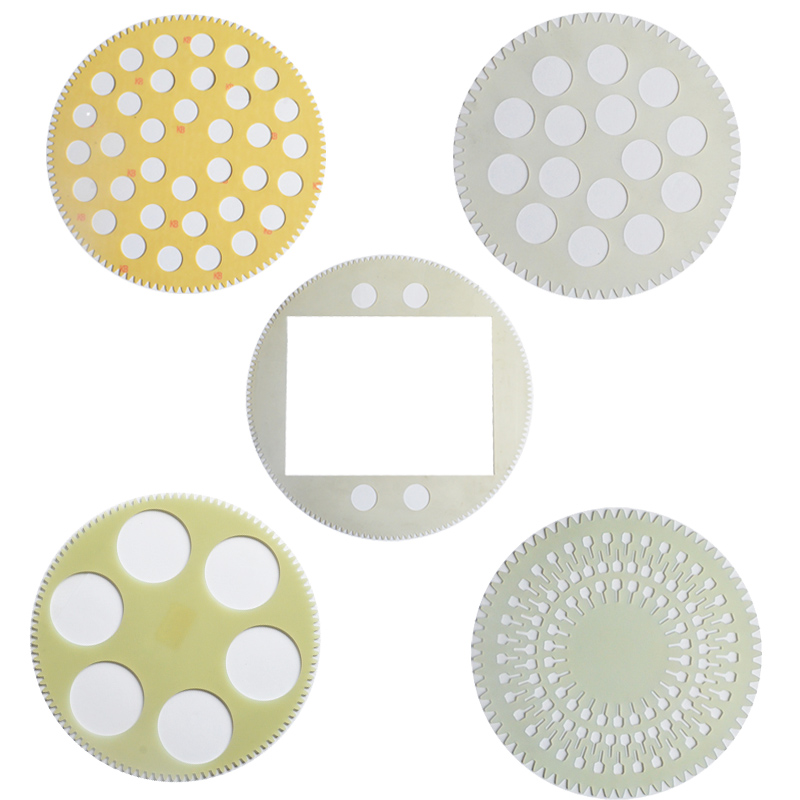

Fr4 garolite g10 sheet material lapping carrier polishing refers to the use of mechanical or chemical reactions to process objects, so that the original rough surface of the product becomes smooth and flat. Some products, such as mirrors, gemstones, mobile phone screens and silicon chips, need to be polished before they can be used. Fr4 garolite g10 sheet material lapping carrier is commonly used polishing tools. According to the different materials, it can be divided into two types of blue steel and epoxy plate. The wear resistance of blue steel is good, but the manufacturing process is complex, the price is very expensive. The epoxy Fr4 garolite g10 sheet material lapping carrier not only has good performance, but also the price is also cheap, and it is very popular. FR4 material is one of the most outstanding cost-effective epoxy plates. In this article, we will talk about the FR4 epoxy sheet material lapping carrier.

When the FR4 epoxy sheet material lapping carrier is working, it runs at a high speed and produces rolling pressure and micro cutting force on the surface of the product that needs polishing. The uneven places gradually become smooth and the final brightness can be seen. When two substances rub against each other, they produce high temperatures and very high losses. FR4 epoxy sheet material lapping carrier has high temperature resistance, wear resistance, high strength, light weight, corrosion resistance and good toughness. It will not be damaged in high temperature, and will wear out after long time of friction, with a long service life. ZTelec Group technology uses CNC precision engraving technology to process carrier of lapping machine. The drawing data is converted into code and input into the computer for automatic production. The production cycle time is short and the efficiency is high. The size of the product is consistent with the size on the drawing, without deviation, and there is no trace of machining on the cutting surface.

ZTelec Group is an enterprise to provide processing services. If you have the demand for electrical insulation Fr4 garolite g10 sheet material lapping carrier, welcome to provide us a drawing or a sample, we will give you the most preferential price. Besides this, we can also processing other plastic mechanical parts, such as: the PC board, PVC board, ABS board, PP board, PET, wood, acrylic, etc. They are also good and inexpensive, and are widely welcomed by our customers.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri