How to choose insulating crepe paper for transformer?

Insulating crepe paper is an essential raw material for many transformer manufactures, and it is mainly used for wrapping transformer leads.

Insulating crepe paper is made of electrical insulating paper (such as kraft paper) after crumpling. It can make the electric field inside the transformer more uniform.

Application fields of insulating crepe paper:

Insulating crepe paper is mainly used in oil-immersed transformers, reactors and transformers.

How to choose insulating crepe paper for transformer?

1. Paper used between layers.

- 1.In general, the proper matching of insulating paper and wire diameter is as follows:

- 2.Available 0.02 capacitor paper with wire diameter less than 0.1 mm,

- 3.Commonly used 0.03 capacitor paper with a wire diameter of 0.08~0.15;

- 4.If the wire diameter is 0.13-0.17, it is possible to use 0.04 paper;

- 5.Commonly used 0.05 crepe paper with a wire diameter of 0.15~0.41;

- 6.Commonly used 0.08 crepe paper with a wire diameter of 0.35~0.64 (0.81);

- 7.0.10~0.12 crepe paper is used for wire diameters greater than 0.55 mm,

- 8.0.15 paper is used for larger diameters (above 1 mm).

2.Paper between groups

- 1. Between groups, use at least 3 layers of 0.12 crepe paper, or one layer of polyester coated paper or silk cloth, or several layers of "green fish paper" or coated green fish paper of corresponding thickness. The total thickness of several layers is not less than 0.36.

- 2. For cows greater than 100VA, the insulation between groups must be thicker.

- 3.Only when the power is very small (below 3W), some see a combination of several layers with a total thickness of 0.24.

-

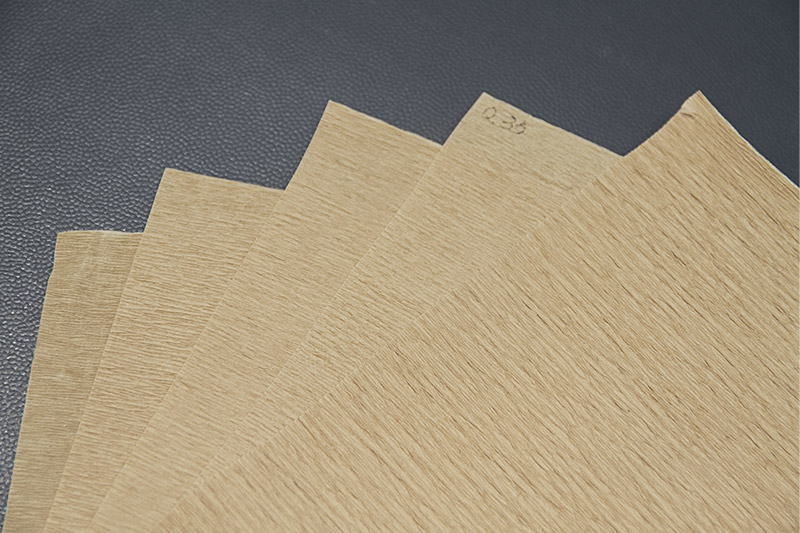

Appearance of crepe paper:

1. Stunning crepe paper is evenly wrinkled,

2.the paper cannot be damaged, the cut edge should be neat, the thickness should be uniform,

3. there should be no impurities, pinholes, water edges and pulp blocks on the paper surface.

Product features of insulating crepe paper:

1. High voltage resistance and insulation;

2. Mechanical toughness;

3. High temperature resistance and heat insulation

4. Non-toxic;

5. Low temperature performance;

6. Not sensitive to moisture

7. Radiation resistance;

ZTelec Group's insulating crepe paper is very suitable for oil-immersed transformers. It is an Electrical Grade A Class Transformer Insulation Crepe Kraft Paper.It also have performed good in reactors and transformers.

That's have a look at it.

Product Features of Electrical Insulation Crepe Paper for Transformer -ZTELEC

1.Insulation class A (105 °C)

2.Color : natural brown, beige

3.High purity and high oil-absorption

4.Good dielectric strength

5.Excellent compatibility with insulating liquids (mineral oils, silicon oils and ascerol oils)

6.Free from conductive particles

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri