Applications of FR4 Epoxy Sheets in Dry-Type and Oil-Immersed Transformers

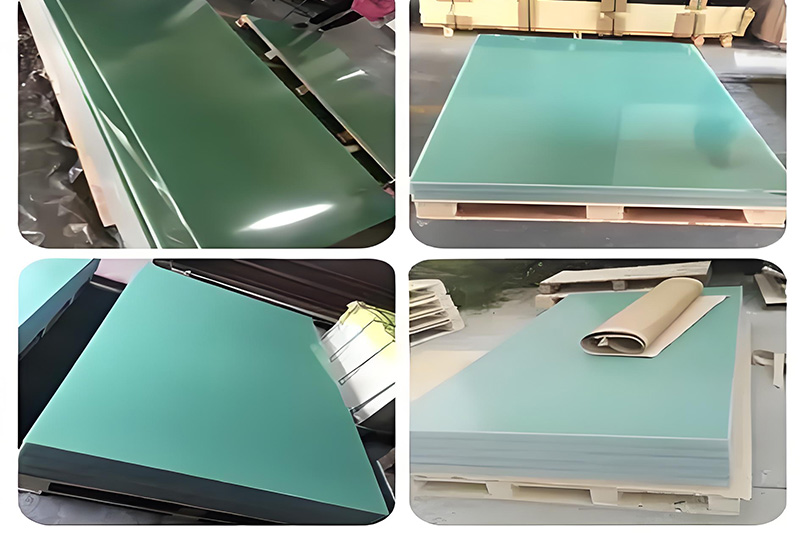

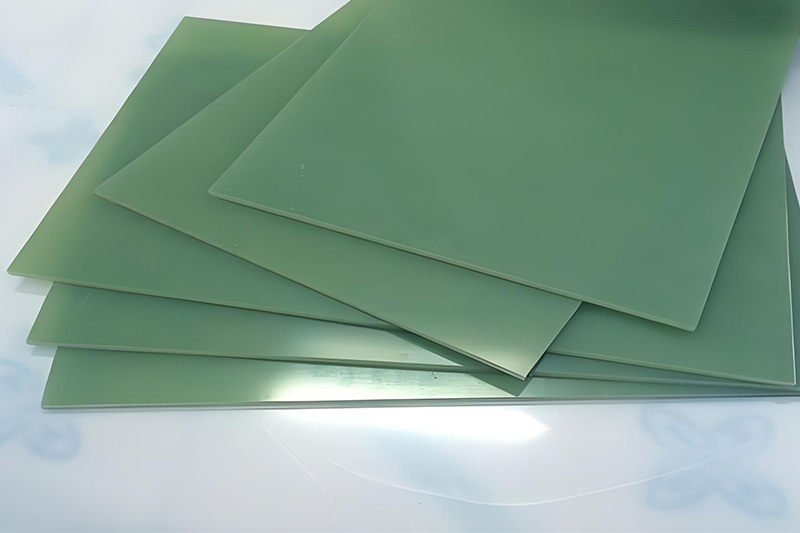

FR4 (commonly seen in light green) is a high-performance thermosetting resin-based composite material with self-extinguishing properties, playing a vital role in the field of electrical insulation. It is sheet product that is produced by impregnating specialized electronic-grade fiberglass cloth with epoxy phenolic resin and then laminating it under high temperature and high pressure.

This material offers excellent mechanical and dielectric properties, as well as outstanding insulation performance, heat resistance, and moisture resistance. Additionally, FR4 epoxy sheets exhibit good machinability and are available in various colors such as white, yellow, light green, and black to meet diverse application requirements.

In the industry, depending on its specific usage, FR4 is also referred to as FR-4 Epoxy Glass Cloth, insulation sheet, or simply epoxy sheet.

Application of FR4 Epoxy Sheets in Dry-Type Transformers

Dry-type transformers use air as the cooling medium and do not rely on liquid insulation, which places extremely high demands on the performance of solid insulating materials. Thanks to its outstanding properties, FR4 epoxy sheet is widely used in dry-type transformers, mainly in the following areas:

1.Insulating Structural Components

Winding Support and Isolation: FR4 epoxy sheets are commonly used to fabricate critical components such as interlayer insulation blocks, end barriers, and winding spacers. These components play a vital role in maintaining safe insulation distances between windings and between windings and the core, thereby preventing electrical breakdown and ensuring safe and stable transformer operation.

Framework (Coil Supports): As structural supports for windings, coil frameworks must withstand mechanical stresses generated during transformer operation, such as electromagnetic forces, and endure high-temperature conditions (dry-type transformers typically use H-class insulation, rated for temperatures above 180 °C). FR4 epoxy sheet, with its excellent mechanical strength and heat resistance, is highly reliable in fulfilling this demanding function.

Lead Fixation: FR4 epoxy sheets are also used to secure lead wires in place within dry-type transformers. This prevents displacement of the leads during operation, avoiding insulation failure caused by movement, and further enhancing transformer reliability.

2.Key Performance Advantages

High-Temperature Resistance: FR4 epoxy sheets have a glass transition temperature (Tg) exceeding 130 °C, enabling them to perform reliably under the high-temperature operating conditions of dry-type transformers. They maintain stable physical and electrical properties over long-term exposure to heat.

Flame Retardancy: The material meets UL94 V-0 flame-retardant standards and offers excellent fire resistance. In the event of fire, FR4 can effectively suppress flame spread, greatly reducing fire risks and enhancing operational safety.

Mechanical Strength: FR4 epoxy sheets feature high flexural and impact strength, enabling them to endure the substantial mechanical stresses caused by short circuits or fault conditions. This ensures the structural integrity and stability of the transformer.

Typical Applications: FR4 epoxy sheets are extensively used in high-frequency transformers, reactors, and dry-type transformers for rail transit systems, especially in compact designs. In such applications, the superior performance of FR4 fully meets the stringent requirements for insulation materials and contributes to enhanced equipment reliability and efficiency.

Application of FR4 Epoxy Sheets in Oil-Immersed Transformers

Oil-immersed transformers use insulating oil as their primary cooling and insulation medium. Although the use of FR4 epoxy sheets in oil-immersed transformers is more limited compared to dry-type transformers, they still play an indispensable role in certain specific scenarios:

1.Insulating Components in Oil

Spacers and Blocks: FR4 epoxy sheets are used to manufacture spacers and blocks that provide insulation support between windings or between the windings and the transformer core. In practical applications, these components must withstand long-term immersion in insulating oil. Therefore, their oil compatibility must be verified to ensure stable performance over extended operational periods.

Lead Insulation: When high-voltage leads pass through the transformer tank, FR4 epoxy sheets can be used to provide reliable mechanical support and electrical insulation. This ensures the safe operation of the leads in oil-immersed environments.

2.Special Requirements

Oil Resistance: For FR4 epoxy sheets used in oil-immersed transformers, specially treated oil-resistant epoxy resins must be selected. This prevents issues such as swelling or degradation caused by long-term oil exposure, thereby ensuring the reliability of insulation components.

Dielectric Strength: In oil-paper composite insulation systems, the dielectric constant of FR4 must be compatible with both the insulating oil and the insulating paper. This helps to avoid localized electric field intensification, which could otherwise lead to insulation failure.

Limitations: In oil-immersed transformers, insulating paper and laminated wood are typically the primary insulation materials. FR4 epoxy sheets are generally used only for specific critical components, due to their relatively higher cost and particular performance characteristics.

Important Considerations

1.For Dry-Type Transformers

When using FR4 epoxy sheets in dry-type transformers, special attention must be paid to their thermal aging performance. Prolonged exposure to high temperatures may lead to resin degradation in FR4, potentially compromising its insulating properties. Therefore, rigorous evaluation and monitoring of thermal aging behavior are essential to ensure the safe and reliable operation of the transformer.

2.For Oil-Immersed Transformers

Before using FR4 epoxy sheets in oil-immersed transformers, it is crucial to thoroughly test their oil absorption rate and resistance to oil corrosion. This helps avoid any adverse chemical reactions with the insulating oil that could lead to reduced insulation performance. Only FR4 sheets that pass strict compatibility and performance tests should be used in oil-immersed applications.

3.Alternative Material Options

For oil-immersed transformers, more cost-effective alternatives such as Nomex paper or laminated wood may be more suitable. In dry-type transformers, if budget constraints are a concern, modified polyester sheets could serve as a viable substitute. In all cases, the selection of insulation materials should be based on specific application requirements and cost considerations, ensuring the optimal balance between performance and affordability.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer