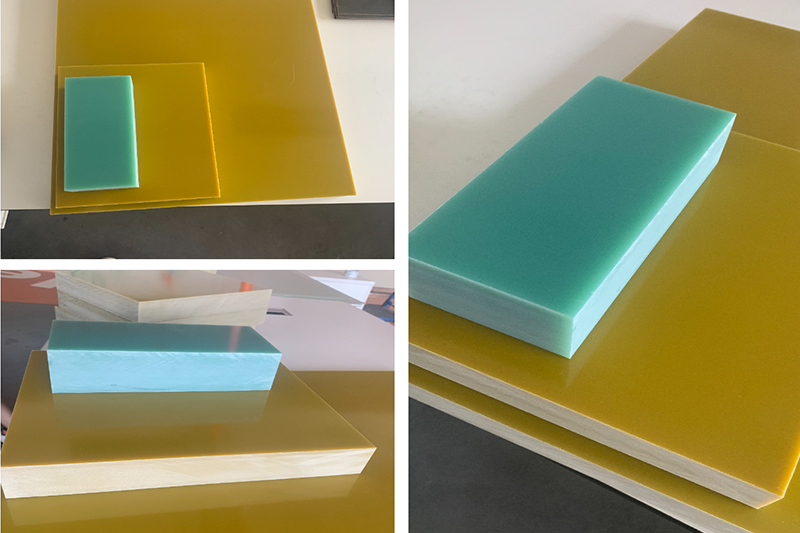

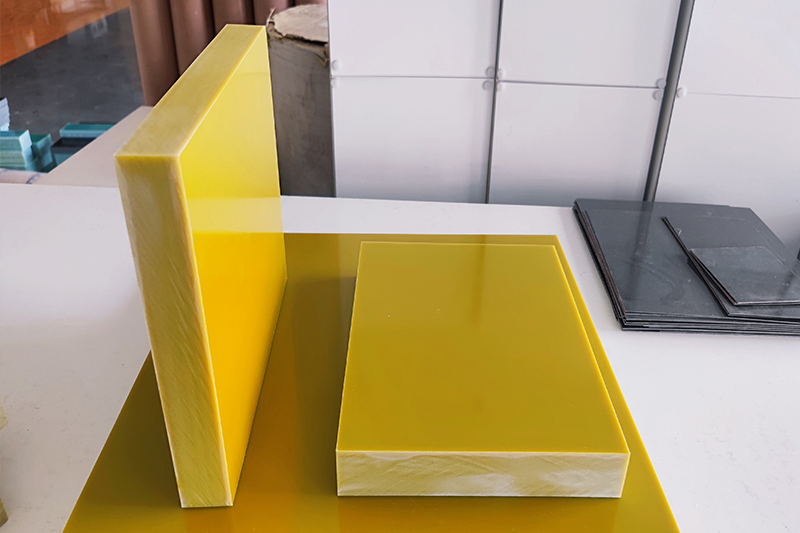

Applications of EPGC203 Insulation Epoxy Glass Fabric Laminated Sheets

As a high-performance industrial base material, EPGC203 insulating epoxy glass fiber laminate is primarily valued for its insulation and structural functions. It is made by impregnating electronic-grade, alkali-free glass fabric with epoxy resin, followed by high-temperature, high-pressure thermosetting. The material offers excellent mechanical properties, electrical insulation, heat resistance, and chemical resistance, making it widely used in industrial sectors requiring high strength, high insulation, and high stability.

EPGC203 Epoxy Glass Fabric Laminated Sheets Code Interpretation

Before discussing its applications, it is useful to understand the meaning of each part of the EPGC203 code:

EP: Stands for Epoxy Resin, the key base material of the laminate, determining crucial properties such as chemical resistance and adhesion.

G: Represents Glass Fabric, which provides mechanical reinforcement, giving the laminate good tensile and bending strength.

C: Typically denotes Copper-clad laminate, but in EPGC203, it generally refers to a non-copper laminate for mechanical structural use, distinguishing it from laminates intended for PCB fabrication.

203: A manufacturer-specific model code, usually indicating performance grade, such as mechanical strength and heat resistance. This model corresponds to, or is similar to, the EPGC type material defined in China’s GB/T 1303.2 standard.

Main Application Areas of EPGC203 Epoxy Glass Fabric Laminated Sheets

1.Electrical Insulation (Core Application)

This is the most traditional and critical application area for EPGC203. In this field, it is primarily used to manufacture various electrical insulating structural components, including:

Insulating Gaskets and Pads: Commonly installed inside transformers, motors, current transformers, switchgear, and other equipment. They isolate components at different potentials and withstand electrodynamic forces caused by short-circuit currents, ensuring safe operation.

Insulating Barriers: Used in high-voltage switchgear (e.g., GIS) and distribution boxes as inter-phase or phase-to-ground insulation, effectively preventing electrical accidents.

Circuit Breaker Arc-Extinguishing Plates: Applied in air or vacuum circuit breakers. These components must provide insulation and arc separation, requiring high arc resistance and tracking resistance.

Transformer Frames/Spools: Serve as the coil winding skeleton, requiring excellent insulation, dimensional stability, and temperature resistance during use.

Support Insulating Components for Cable Terminations and Joints: Provide structural support and maintain insulation performance, ensuring stable power transmission in cable systems.

2.Mechanical and Structural Applications

Thanks to its high strength and lighter weight compared to metals, EPGC203 is widely used in mechanical settings that require insulation:

Structural Support Components: Serve as insulated beams, brackets, or linkages within equipment. Examples include pantographs in rail transit or high-voltage testing devices.

Gears and Bearing Pads: Suitable for specialized environments (e.g., where electrical corrosion must be avoided) or light-load transmission mechanisms. Since its wear resistance is lower than that of engineering plastics, it is typically used in applications with infrequent operation.

Jigs and Fixtures: In electronics assembly and soldering processes, used as insulating jigs to secure PCBs or components, ensuring precision and safety during production.

Brief Comparison with Similar Materials

1.FR-4 Epoxy Glass Fiber Sheet

FR-4 Epoxy Glass Fiber Sheet: Typically refers to copper-clad laminate, mainly used for manufacturing printed circuit boards (PCBs). It emphasizes consistency in electrical performance, dielectric constant, and etchability.

EPGC203 Epoxy Laminate: More oriented toward mechanical and structural applications, with a focus on mechanical strength, thickness tolerance, and arc resistance. Although both materials share similar components, the type of glass cloth and resin formulation may differ to meet distinct performance standards. In many structural applications, they can be used interchangeably, but EPGC203 is considered the more specialized designation for structural insulation.

2.GPO-3 Polyester Glass Fiber Laminate

GPO-3 Polyester Glass Fiber Laminate: Made with unsaturated polyester resin, usually lower in cost and widely applied in less demanding scenarios, such as low-voltage motor slot wedges and gaskets.

EPGC203 Epoxy Laminate: Uses epoxy resin as the base material, offering superior mechanical strength, heat resistance, chemical resistance, and adhesion compared to GPO-3, making it better suited for industrial applications requiring higher material performance.

Typical Applications and Selection Guidelines

Common applications of EPGC203 epoxy glass fiber insulating laminate include:

Insulating structural components in high-voltage electrical equipment (e.g., switchgear, transformers).

Precision jigs and fixtures used in electronic product testing.

Mechanical supports and fixtures requiring high strength and insulation.

When deciding whether to use EPGC203, one should avoid blind selection. Instead, consider factors such as operating temperature conditions, voltage levels, mechanical loads, and chemical environments. A comprehensive evaluation ensures the material’s properties are fully leveraged, guaranteeing the stability and safety of the equipment or production process.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer