Judgment and Handling Methods of Internal Faults in Dry-Type Transformers

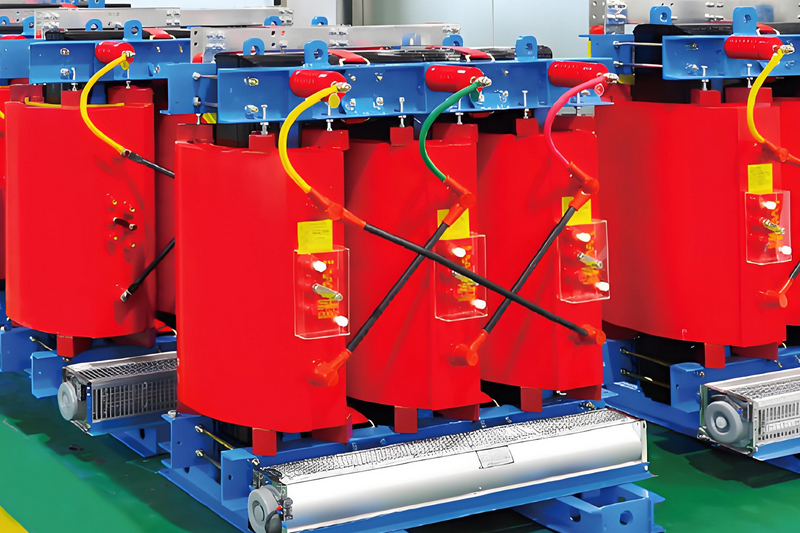

Dry-type transformers are vital equipment in modern power systems. Internal faults, if not detected and resolved in time, may lead to equipment damage, power supply interruptions, or even serious safety accidents. Accurate judgment and proper handling are therefore essential for maintaining safe and stable operation. This article provides detailed methods for identifying and managing internal faults in dry-type transformers, making it a valuable reference for engineers, maintenance personnel, and transformer manufacturers.

Methods for Judging Internal Faults in Dry-Type Transformers

The core principle of fault identification is to combine direct sensory judgment with instrument-based testing and analysis. This dual approach helps achieve accurate and reliable results.

1. Sensory Judgment

Smell: If a strong burning odor is detected, it often indicates overheating or burning of insulation varnish, epoxy resin, or wire insulation. In this case, the transformer must be shut down immediately.

Visual Inspection:

- Color Change: Darkened, blackened, or carbonized traces on the coil surface are signs of severe overheating.

- Cracks/Damage: Cracks in epoxy resin cast coils reduce insulation strength and increase safety risks.

- Discharge Marks: Black scorch marks or creepage traces near coils or terminals suggest partial discharge faults.

- Foreign Matter: Metallic debris, heavy dust, or small animal remains inside the transformer can trigger malfunctions.

Sound: A healthy transformer emits a steady “humming” sound. Irregular sharp noises or crackling sounds may indicate loose components or internal discharges.

Touch (Temperature): With strict safety precautions, touch the casing briefly using the back of your hand. Local overheating may signal inter-turn short circuits or other internal faults.

2. Instrument Testing and Analysis

Insulation Resistance Test: Using a megger or insulation resistance tester, measure resistance between HV and LV windings, HV to ground, and LV to ground. A significant drop in resistance indicates insulation damage or moisture ingress.

DC Resistance Test: Test each phase winding with a DC resistance tester. If resistance imbalance exceeds ±2% or deviates from factory values, possible causes include loose connections, poor soldering, or inter-turn short circuits.

Winding Temperature Monitoring: With PT100 sensors, monitor winding temperatures continuously. Abnormal spikes or exceeding alarm thresholds signal overheating or cooling system failures.

Handling Methods for Internal Faults in Dry-Type Transformers

1. Emergency Handling Procedures

- Immediate Power Cut-off: Disconnect both HV and LV switches, and display a “Do Not Operate” warning sign.

- Safety Isolation: Follow voltage verification, discharge, and grounding steps to ensure safe isolation.

- Emergency Evacuation: If smoke or fire is present, evacuate personnel immediately.

- Initial Firefighting: Only use dry powder or CO₂ extinguishers under safe conditions. Never use water for transformer fires.

2. Follow-up Handling

- Professional Assistance: Internal faults should not be handled by non-professionals. Contact the transformer manufacturer or certified service provider.

- Fault Analysis: Experts will carry out core inspections and electrical tests such as insulation resistance, DC resistance, and turns ratio tests to locate the root cause.

- Repair or Replacement: Based on damage severity, options include coil repair in the factory or complete replacement of the transformer.

By strictly following fault judgment and handling procedures, operators can significantly reduce the risk of dry-type transformer failures. Combining sensory judgment with advanced testing tools ensures accurate diagnostics, while proper emergency and follow-up handling protects both equipment and personnel. Ultimately, systematic maintenance and professional repair services are key to ensuring the stable and safe operation of power systems.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer