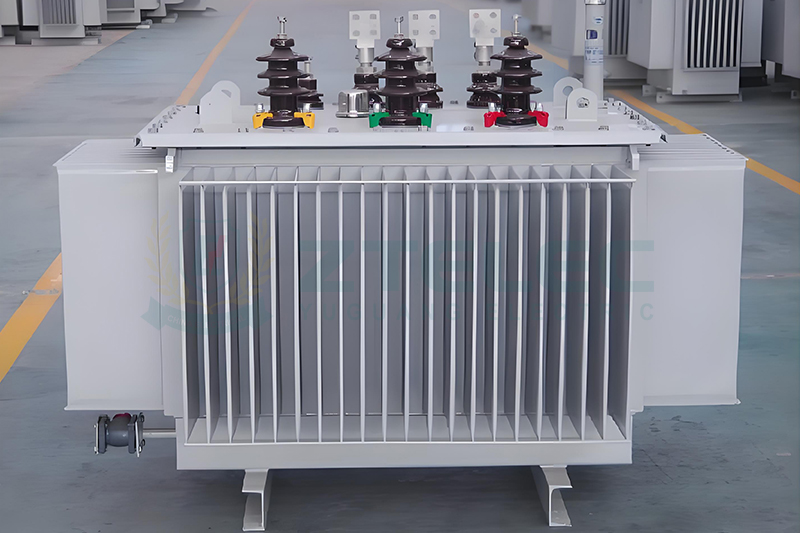

From 30kVA to 31500kVA: Key Points for Capacity Calculation and Selection of 10kV Oil-Immersed Transformers

In industrial, commercial, and infrastructure power systems, 10kV oil-immersed transformers are the essential equipment for power conversion. The proper selection of transformer capacity directly affects investment costs, operating efficiency, lifespan, and the system’s ability to handle future load growth.

1. Importance of Capacity Selection

Initial investment: Larger transformer capacity increases purchase and installation costs.

Operational efficiency: Transformers achieve maximum efficiency near their rated capacity. Oversized units cause light-load operation, increasing no-load losses and energy waste.

Equipment lifespan: Overloading accelerates insulation aging and increases the risk of faults.

System scalability: Reasonable capacity selection ensures adaptability to future power demand growth.

2. Transformer Capacity Calculation

To determine the required capacity (kVA) for a 10kV oil-immersed transformer, the actual electrical load must be considered. The basic formulas are as follows:

Single-phase transformer: Capacity (kVA) = Voltage (V) × Current (A) / 1000

Three-phase transformer: Capacity (kVA) = √3 × Line Voltage × Line Current / 1000

Example: For a 10kV/0.4kV transformer with a secondary current of 500A, the capacity is approximately √3 × 400 × 500 / 1000 = 346kVA.

3. Key Considerations for Capacity Selection

Load Characteristic Analysis

Stable load: Consistent electricity usage with minimal fluctuations.

Fluctuating load: Varying usage requires capacity consideration based on peak demand.

Impact load: Generates high inrush current; consider larger capacity or use soft-start technologies.

Future Development Margin

Transformers typically operate for over 20 years. Capacity planning should consider load growth over the next 5–10 years, with a recommended expansion margin of 15%–25%. However, this should be balanced rather than directly choosing an oversized unit.

Energy Efficiency Standards and Losses

No-load loss (iron loss): Occurs whenever the transformer is energized, regardless of load. Low no-load loss is ideal for long-term light-load operation.

Load loss (copper loss): Increases with higher load and is proportional to the square of current. Choose transformers with low load losses for near-full-load operation.

Total Cost of Ownership (TCO): A lower-priced transformer may have higher operational losses, increasing long-term electricity costs.

Cooling Methods (ONAN vs. ONAF)

ONAN (Oil Natural Air Natural): Suitable for 30kVA–2500kVA small transformers. It uses natural oil and air circulation for cooling, offering simple design and easy maintenance.

ONAF (Oil Natural Air Forced): Ideal for 3150kVA–31500kVA medium to large transformers. Radiators with fans enable forced cooling, improving capacity and efficiency. Fans can be turned off at low load to save energy and reduce noise.

4. Application Scenarios and Capacity Selection Suggestions

30kVA – 500kVA: Common in small commercial areas, rural power networks, and residential communities.

Selection focus: Cost-effectiveness, easy installation, low no-load loss.

630kVA – 2500kVA: Typical range for industrial plants, mines, and large commercial buildings.

Selection focus: Load loss, system reliability, compatibility with existing networks.

3150kVA – 10000kVA: Suitable for large industrial projects, substations, and data center backup systems.

Selection focus: Cooling method (ONAF), protective devices (gas relays, pressure valves), scalability.

12500kVA – 31500kVA: Used in heavy industries (steel, chemical) and large infrastructure projects.

Selection focus: Customized technical design, economic evaluation, and system short-circuit capacity analysis.

5. Summary and Expert Advice

When selecting a 10kV oil-immersed transformer from 30kVA to 31500kVA, the process must combine accurate load calculation, load type analysis, future expansion planning, efficiency evaluation, and cooling method selection.

Before finalizing your selection, consult a professional electrical engineer or a trusted transformer manufacturer. Providing detailed power consumption data and operational scenarios ensures you receive a reliable, safe, and cost-effective transformer solution tailored to your project needs.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer