DDP Insulating Paper Manufacturers, Suppliers, Dealers, and Price

DDP insulating paper is a high-performance, low-dissipation insulating paper coated with a specially modified epoxy resin, creating a diamond-shaped structure. It is commonly used as turn insulation and interlayer insulation for oil-immersed power transformer coil conductors. During the drying process, the resin coating melts at a certain temperature and forms an adhesive bond. As the temperature continues to rise, the coating solidifies, firmly bonding the winding layers together. This bond effectively prevents winding displacement during a short circuit, thereby ensuring the long-term mechanical and electrical performance of the insulation structure. Due to the dot-shaped distribution of the resin, DDP also facilitates the infiltration of transformer oil and the escape of gases within the insulation material, effectively suppressing corona and partial discharge, ensuring a stable and reliable insulation structure.

DDP insulating paper is widely used in motors, transformers, and other electrical equipment due to its excellent mechanical strength, good electrical insulation properties, and outstanding heat resistance. Whether you are an engineer, procurement specialist, or business decision-maker, it is crucial to understand the relationships between manufacturers, suppliers, and dealers, as well as the pricing structure, when purchasing DDP insulating paper. This guide will provide you with a one-stop answer.

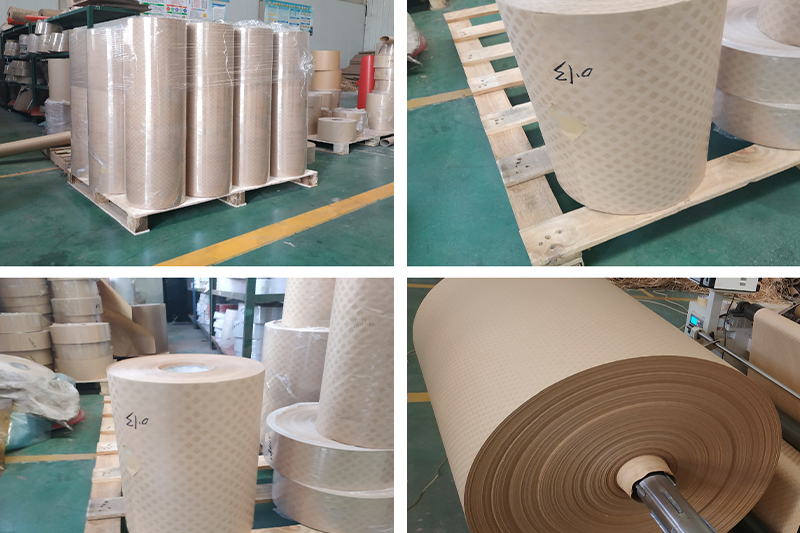

DDP Insulation Paper Manufacturers

Manufacturers are the source of DDP insulation paper production, possessing complete production lines, raw material reserves, and technical formulas. Selecting a high-quality manufacturer is essential for ensuring product quality and stable supply.

They oversee the entire production process from raw materials to finished product, including pulping, forming, calendering, and slitting. They rigorously control key parameters such as thickness, density, tensile strength, and electrical strength.

How to Find:

♦ Search "DDP Insulation Paper Manufacturer" on platforms like Alibaba and Google.

♦ Attend specialized exhibitions on electrical insulation materials or composite materials.

♦ Look for brands with a strong reputation in the insulation materials industry.

The advantages of working with a manufacturer include more competitive pricing, customizable specifications such as thickness, width, and roll diameter, and direct technical support.

DDP Insulation Paper Suppliers and Dealers

Supplier is a broad term that can refer to the manufacturer itself or intermediaries such as trading companies. Dealers, on the other hand, focus on product sales and distribution and do not participate in production.

Supplier:

This may be a manufacturer selling directly or a trading company holding inventory.

They typically offer multiple brands and specifications of insulation materials, making them suitable for one-stop shopping.

Dealers:

Bulk purchases from the manufacturer are then sold in small batches to end users.

The core value lies in localized service, fast delivery, flexibility in small-batch purchasing, and inventory management, making them suitable for small-volume or urgent replenishment needs.

How to choose?

Large-scale projects or long-term, stable demand → Prioritize manufacturers for better pricing and guaranteed supply.

Multi-category, small-batch purchases or urgent sample needs → Prioritize suppliers or distributors for flexible service and fast response.

Key Factors Affecting DDP Insulation Paper Prices

DDP insulation paper prices are influenced by multiple factors, and understanding these factors can help explain price differences.

✦ Raw Material Cost:

Wood pulp, the primary raw material, is subject to fluctuations in its international market price, which directly impacts finished product pricing.

✦ Specifications:

Thickness: Typically measured in millimeters or microns. Thickness increases with the amount of material used, leading to higher prices.

Density: High-density products offer superior mechanical and electrical performance, but require more complex production processes, resulting in higher prices.

Grades: Products with different electrical properties (such as breakdown voltage) and heat resistance levels vary significantly in price.

✦ Purchase Quantity:

Minimum Order Quantity: Manufacturers typically set a minimum order quantity, with larger orders resulting in lower unit prices.

Long-term Orders: Signing long-term agreements typically offers more favorable prices.

✦ Market Supply and Demand:

Developments in industries such as energy and rail transit influence demand, and prices tend to rise when supply exceeds demand.

✦ Brands and Certifications:

Well-known brands and products certified by international certifications such as UL and ISO9001 typically command higher prices due to their proven quality.

✦Additional Services and Costs:

Custom Slitting: Slitting to specific widths may incur additional charges.

Logistics and Taxes: International trade terms (such as FOB, CIF, and DDP) will affect final delivery costs, including freight, insurance, and other costs.

If you're looking for a reliable DDP insulation paper partner, please contact us. As an experienced insulation material manufacturer, we offer competitive pricing, strict quality control, and efficient logistics. Please provide us with your detailed requirements and we'll provide you with a personalized quote and technical support.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer