Analysis of the Insulation Performance of Aramid Paper

In high-end fields such as new energy vehicles and power electronics, the performance requirements for insulating materials are extremely stringent. They must achieve current insulation while withstanding high temperatures, high pressures, and severe mechanical stress. Among various insulating materials, aramid paper, with its unique comprehensive performance, has become the choice of engineers and designers. This article will analyze the insulation performance of aramid paper, explain its scientific principles, and introduce its application scenarios.

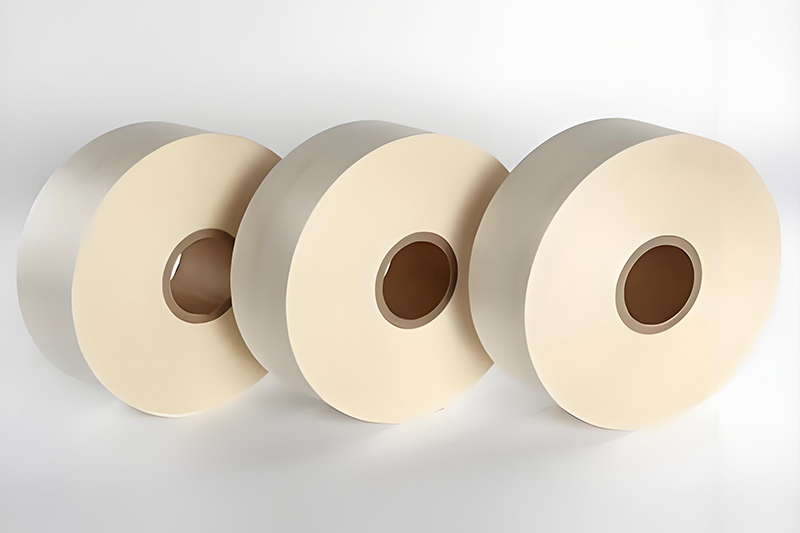

Introduction to Aramid Paper

Aramid paper is a nonwoven fabric material made from aramid short fibers and aramid precipitated fibers through a papermaking process. Its core raw material is "para-aramid" (such as DuPont Kevlar®), a polymer material with high strength, high modulus, and good thermal stability. Aramid paper is not ordinary paper, but a high-tech engineering material with a dense structure and uniform performance, possessing the excellent characteristics of aramid fibers.

Analysis of Aramid Paper Insulation Performance

The insulation performance of aramid paper is formed by the combined effect of several excellent properties.

1. High Temperature Resistance

High-grade heat resistance (H class and above): Aramid paper can operate stably at 220°C for extended periods, and its short-term temperature resistance can reach over 300°C. Its glass transition temperature exceeds 300°C, and it does not melt or drip at high temperatures.

Flame retardancy: Aramid paper has flame retardant properties, with a limiting oxygen index (LOI) greater than 20%. When exposed to fire, it forms a carbonized layer, isolating oxygen and preventing the spread of flames.

2. Mechanical Strength and Toughness

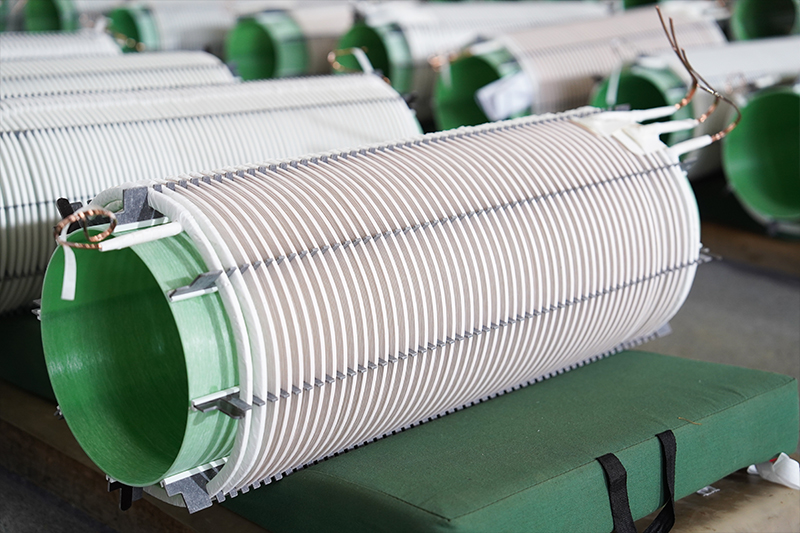

Tear and puncture resistance: In applications such as motor slot insulation and phase-to-phase insulation, aramid paper can withstand the compression of sharp edges of windings and the mechanical stress during assembly, preventing insulation failure due to damage.

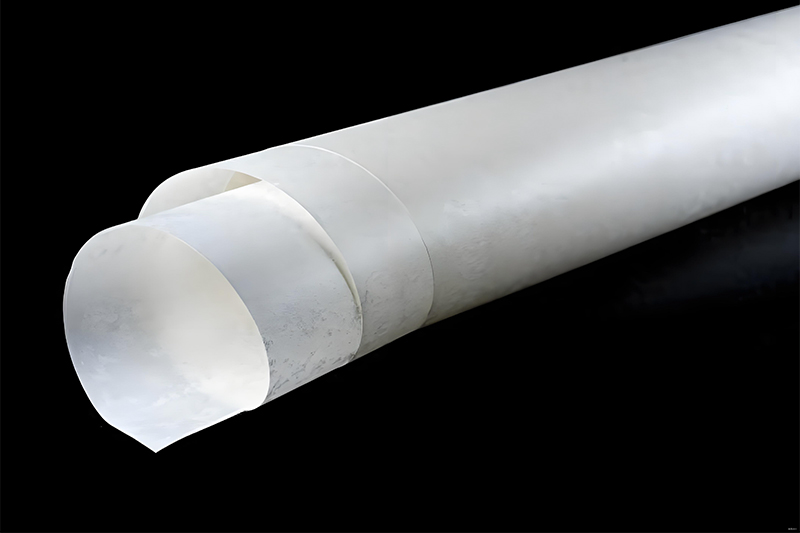

Flexibility: Aramid paper has high strength and good flexibility, which makes it easy to fold, wrap and process. It can adapt to complex insulation structure design.

3. Dielectric Properties

High Dielectric Strength: Aramid paper can withstand high breakdown voltage per unit thickness, providing reliable insulation protection in high-voltage environments.

Low Dielectric Constant and Dielectric Loss: In high-frequency applications such as variable frequency motors, this characteristic reduces energy loss and signal delay, improving equipment efficiency.

4. Chemical Stability and Environmental Adaptability

Aramid paper is resistant to most organic solvents, oils, and chemical reagents. It is suitable for equipment that needs to be impregnated with insulating varnish or operates in oil environments (such as transformers). It also possesses moisture resistance and radiation resistance, maintaining stable performance over long periods in harsh environments.

Applications of Aramid Paper Insulation Properties

Motor Insulation: Aramid paper is used in high-efficiency motors, traction motors, and explosion-proof motors as slot insulation, phase-to-phase insulation, and gasket insulation materials.

Transformer Insulation: Aramid paper is used for interlayer insulation and insulation barriers in dry-type transformers and oil-immersed transformers.

New Energy Vehicles: Aramid paper is used in drive motors and lithium battery packs. It serves as tab insulation and battery pack thermal insulation material, ensuring insulation effectiveness and safety.

Key Points for Selecting and Using Aramid Paper

Thickness Selection: Select a suitable thickness within the range of 0.05mm to 0.5mm based on the working voltage and mechanical space requirements.

Pretreatment: Aramid paper is hygroscopic. Pre-drying is recommended before impregnation or vacuum pressure impregnation (VPI) to ensure optimal performance.

Processing Precautions: Use sharp tools during cutting and stamping to avoid edge fraying that could affect insulation performance.

Comparison of Aramid Paper with Other Insulation Materials

1. Compared to asbestos paper, aramid paper has higher mechanical strength and better fire resistance, but is more expensive and harder to process.

2. Compared to PTFE, aramid paper has higher mechanical strength and better insulation performance, but poorer corrosion resistance.

3. Compared to fiberglass cloth, aramid paper has better insulation performance, but lower mechanical strength and a higher price.

The insulation performance of aramid paper is determined by its high-temperature resistance, mechanical toughness, dielectric stability, and chemical inertness. While it is not a low-cost material, aramid paper offers value justified by its cost for high-end electrical equipment with stringent requirements for safety, reliability, and lifespan. As electrification and intelligent technologies advance, the importance of aramid paper as a key basic material will continue to increase.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer