Applications of Heat-Resistant Crepe Paper in Transformers

In power equipment manufacturing, the performance of insulation materials directly affects transformer operational safety, service life, and long-term reliability. Heat-resistant crepe paper features excellent electrical insulation properties, high-temperature resistance, and outstanding mechanical flexibility. It has been widely used in oil-immersed transformers and certain special transformers, serving as a key component of the winding insulation system.

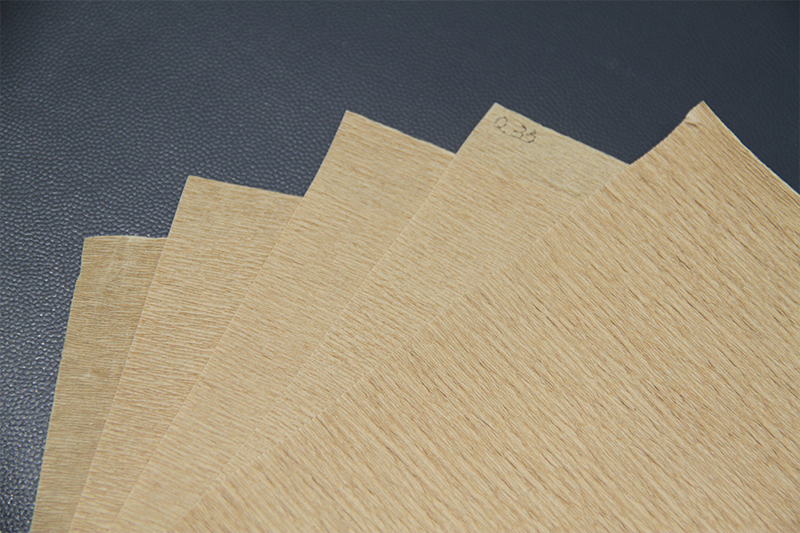

Overview of Heat-Resistant Crepe Paper

Heat-resistant crepe paper is a cellulose-based insulation material processed through special treatment. It is manufactured using a creping process that forms a corrugated surface structure. This insulation material is typically made from high heat-resistance insulating pulp and further enhanced through chemical treatments to improve thermal stability and mechanical strength. Its thermal class generally ranges from 120°C (Class E) to above 220°C (Class C), which is significantly higher than that of conventional insulating paper.

Core Applications of Heat-Resistant Crepe Paper in Transformers

Interlayer Insulation of Windings:

Heat-resistant crepe paper is widely used for interlayer insulation in both high-voltage and low-voltage windings. Its creped surface structure enhances oil impregnation, improves heat dissipation efficiency, and reduces the occurrence of local hot spots.

Turn-to-Turn and Section-to-Section Insulation:

Between winding turns and sections, crepe paper provides stable electrical isolation. At the same time, it offers effective cushioning, reducing damage to the winding structure caused by short-circuit forces.

Lead and Conductor Wrapping:

Heat-resistant crepe paper is commonly used for wrapping transformer leads and copper conductors, ensuring reliable insulation protection even under conditions of vibration and temperature rise.

Structural Filling and Support Insulation:

Within the internal transformer structure, crepe paper can be used for gap filling and auxiliary support, enhancing the integrity and stability of the overall insulation system.

Five Key Technical Advantages of Heat-Resistant Crepe Paper

1. Thermal Resistance

The long-term operating temperature can reach 120-220°C, and it is suitable for temperature rise during transformer operation.

Crepe paper has excellent thermal aging performance and helps extend transformer service life.

Effectively reduces insulation failures caused by overheating.

2. Electrical Properties

High dielectric strength (typically > 12 kV/mm).

Low dielectric loss factor.

Heat-resistant crepe paper effectively suppresses partial discharge.

3. Mechanical Performance

The creped structure provides good flexibility and extensibility.

Crepe paper has high tensile strength, and is capable of withstanding mechanical stress during winding and operation.

Good tear resistance and abrasion resistance.

4. Oil Absorption and Impregnation Performance

The creped structure increases surface area, improving insulating oil impregnation efficiency.

Ensures full impregnation of the insulation system, eliminating bubbles and voids.

Enhances the overall dielectric performance of the insulation system.

5. Environmental Adaptability

Good moisture resistance and chemical resistance.

High compatibility with transformer oil.

An environmentally friendly material that complies with international standards such as RoHS.

Current Application Areas of Heat-Resistant Crepe Paper

Dry-Type Transformers: Suitable for locations with high fire safety requirements, such as high-rise buildings and metro systems.

Oil-Immersed Transformers: Used in distribution transformers and power transformers.

Special Transformers: Applications in high-temperature environments, such as electric furnace transformers and rectifier transformers.

Renewable Energy Sector: Transformers used in wind power and solar power generation systems.

Selection Recommendations for Different Application Scenarios

Distribution Transformers:

B-class or higher heat-resistant crepe paper is recommended to achieve a balance between cost and performance.

Power Transformers:

F-class heat-resistant crepe paper is preferred to meet the requirements of long-term, high-load operation.

Renewable Energy and Special Transformers:

High heat-resistance, high-purity insulation paper is recommended to enhance overall system reliability.

When selecting heat-resistant crepe paper, key factors such as voltage level, operating temperature, insulating oil type, and design service life should be comprehensively considered.

Thanks to its unique creped structure and excellent thermal resistance, heat-resistant crepe paper provides transformers with a reliable and efficient insulation solution. As power equipment continues to develop toward higher efficiency, compact design, and environmental sustainability, ongoing technological innovation in heat-resistant crepe paper will continue to drive progress in the transformer industry. Proper selection and correct application of heat-resistant crepe paper can significantly improve transformer operational reliability, extend equipment service life, and reduce total life-cycle costs, ensuring stable and secure operation of power systems.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer