How Is Insulation Paper Manufactured?

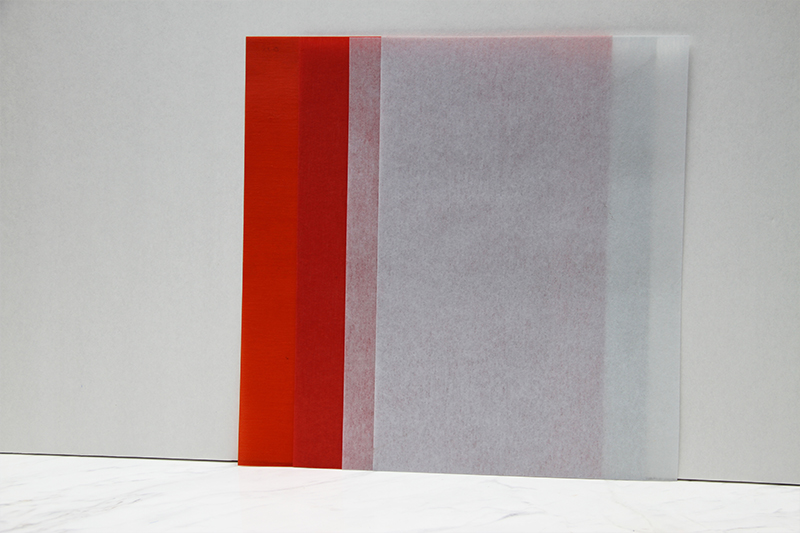

Insulation paper is a critical material used in the core components of power equipment, electronic products, and industrial machinery. It is capable of maintaining stable electrical insulation performance under extreme temperatures, high voltages, and harsh operating environments. This article provides a detailed introduction to the manufacturing process of insulation paper, explaining the transformation from fiber raw materials to high-performance insulating materials.

Insulation paper is a type of specialty paper designed for electrical insulation. It features high dielectric strength, good mechanical properties, and excellent thermal stability. It is mainly used in transformers, motors, cables, and electronic equipment to prevent current leakage and short circuits, ensuring the safe and reliable operation of electrical devices.

Key Raw Materials in Insulation Paper Manufacturing

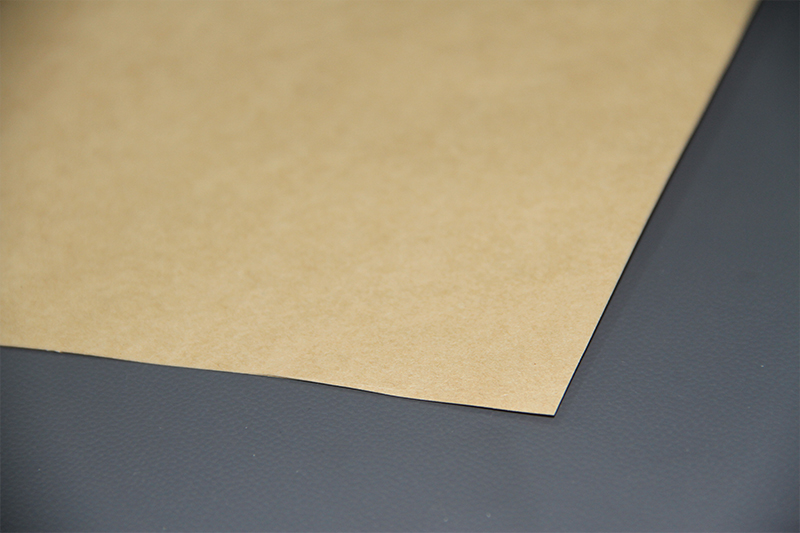

Fiber Raw Material Selection

High-quality insulation paper is typically produced from high-purity wood pulp fibers, which are characterized by:

Long fiber length and minimal impurities

Extremely low ash content

Free from metal ions and conductive contaminants

Commonly used raw materials include:

Softwood pulp (provides mechanical strength)

Refined kraft pulp (enhances electrical insulation performance)

The purity of the raw materials is the primary factor determining the electrical performance of insulation paper.

Insulation Paper Manufacturing Process

1. Fiber Preparation and Treatment

Select fiber raw materials with appropriate specifications according to the required insulation class.

Remove conductive impurities such as lignin and resins.

Separate fibers through mechanical and chemical methods to produce a uniform pulp.

Apply treatments such as phosphorylation and acetylation to the fibers to enhance thermal stability.

2. Papermaking Process

Pulp Preparation and Mixing:

Different types of fibers and additives are blended in precise proportions.

Sheet Formation:

Use a Fourdrinier paper machine or a cylinder paper machine.

Evenly distribute the pulp onto a moving wire screen.

Remove water through gravity and vacuum suction.

Form a continuous wet paper web.

Pressing and Dewatering:

Mechanical pressing further removes water from the wet web and improves fiber bonding.

Drying Process:

Utilize a multi-stage drying system with precise temperature control.

Prevent excessive drying that may cause paper embrittlement.

Ensure dimensional stability of the paper.

3. Impregnation and Post-Treatment

Resin Impregnation:

Pass the dried paper through a resin bath.

Precisely control resin uptake to ensure uniform resin distribution within the paper.

Curing Treatment:

Place the resin-impregnated paper in a high-temperature oven to cure the resin.

After curing, the resin forms a three-dimensional network structure, enhancing the overall performance of the insulation paper.

Calendering and Calibration:

Use calendering equipment to control paper thickness and surface flatness.

Ensure consistent dielectric performance of the insulation paper.

4. Special Treatments

Mica Paper Lamination: Combine mica flakes with the paper substrate to improve high-temperature resistance.

Creping Treatment: Crepe the insulation paper to increase flexibility and elasticity, facilitating coil wrapping.

Coating Treatment: Apply special coatings to the paper surface to enhance oil resistance and chemical corrosion resistance.

Flame-Retardant Treatment: Add flame retardants to the insulation paper to meet safety standard requirements.

Key Quality Control Points

♦ Dielectric Strength Testing: Each production batch is tested to ensure dielectric strength meets insulation standards.

♦ Thickness Uniformity: Use precision instruments to measure , and thickness tolerances is controlled at the micron level.

♦ Porosity Control: Strict control of paper porosity to prevent adverse effects on impregnation performance and dielectric properties.

♦ Thermal Stability Testing: Simulate long-term high-temperature operating conditions to evaluate the stability of insulation paper performance.

♦ Mechanical Property Testing: Evaluate tensile strength, tear resistance, flexibility, and other mechanical characteristics.

Main Applications of Insulation Paper

Oil-Immersed Transformers: Inter-turn insulation, inter-layer insulation, lead wire wrapping, and insulating spacers

Dry-Type Transformers: Auxiliary insulation and composite insulation structures

Motors and Generators: Slot insulation and phase-to-phase insulation

Electrical Equipment: Heat-resistant and high-voltage insulation structures

Factors to Consider When Selecting Insulation Paper

Understanding the insulation paper manufacturing process can support informed procurement decisions. Key considerations include:

♦ Matching Application Requirements: Select the appropriate type of insulation paper based on the equipment’s operating temperature class and voltage rating.

♦ Supplier Capability Assessment: Verify the supplier’s manufacturing processes and quality control systems.

♦ Cost-Performance Analysis: Balance insulation paper performance requirements with manufacturing costs.

♦ Compliance Verification: Ensure the product complies with relevant standards such as IEC, UL, and GB.

Insulation paper manufacturing is a precision technology that integrates materials science, papermaking processes, and electrical engineering. Each production stage directly affects product performance and reliability. As electrical equipment continues to evolve toward higher voltage, higher temperature, and more compact designs, insulation paper manufacturing technologies must continuously innovate to provide safer and more efficient insulation solutions for the power and electronics industries.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer