Electric Transformer FAQs

what is an electrical transformer?

An electrical transformer is a device used to transfer electrical energy between two or more circuits through electromagnetic induction. these electrical devices take electricity from one source, transform its voltage, and then transfer that energy to another circuit.

It operates on the principles of Faraday's law of electromagnetic induction, which states that a changing magnetic field induces an electromotive force (EMF) in a conductor.

The basic components of a transformer include:

-

Primary Winding: The coil of wire connected to the input voltage source is called the primary winding.

-

Secondary Winding: The coil of wire connected to the output load is called the secondary winding.

-

Magnetic Core: The primary and secondary windings are wound around a common magnetic core, typically made of laminated iron or other magnetic materials. The core enhances the magnetic coupling between the windings.

When an alternating current (AC) flows through the primary winding, it creates a changing magnetic field around the winding. This changing magnetic field induces a voltage in the secondary winding through electromagnetic induction. The voltage induced in the secondary winding is proportional to the turns ratio of the primary and secondary windings.

Key features and functions of electrical transformers include:

-

Voltage Transformation: Transformers can step up (increase) or step down (decrease) voltage levels depending on the turns ratio between the primary and secondary windings.

-

Power Transmission and Distribution: Transformers are essential for transmitting electrical power efficiently over long distances and distributing it to homes, businesses, and industries.

-

Isolation: Transformers provide electrical isolation between the primary and secondary circuits, enhancing safety and preventing direct electrical connection.

-

Efficiency: Modern transformers are designed to be highly efficient, minimizing energy losses during the transformation process.

-

Frequency Transformation: Transformers can also be used to change the frequency of an AC power system, although this is less common.

Why do we use transformers?

Transformers are used for various reasons in electrical systems, and they play a crucial role in the generation, transmission, and distribution of electrical energy. Here are some key reasons why transformers are widely used:

-

Voltage Transformation:

- Step-Up Transformers: Increase the voltage from a lower level to a higher level. This is essential for efficient long-distance transmission of electrical power, reducing energy losses during transportation.

- Step-Down Transformers: Decrease the voltage from a higher level to a lower level, making it suitable for safe distribution and use in homes, businesses, and industries.

-

Power Transmission:

- Transformers facilitate the efficient transmission of electrical power over long distances. Higher voltage reduces the current flowing through the transmission lines, minimizing energy losses due to resistive heating.

-

Distribution of Electrical Power:

- Distribution transformers further step down the voltage for local power distribution. They are commonly found on utility poles or in substations, providing electricity to neighborhoods and buildings.

-

Electrical Isolation:

- Transformers provide electrical isolation between the primary and secondary circuits. This isolation is crucial for safety, preventing direct electrical contact and reducing the risk of electrical shock.

-

Impedance Matching:

- Transformers are used to match the impedance between different parts of an electrical system, ensuring optimal power transfer and reducing reflection of power back into the source.

-

Current Transformation:

- Current transformers (CTs) are a specific type of transformer used to measure and monitor current levels in power systems. They are commonly employed in protection and metering applications.

-

Instrument Transformers:

- Transformers are used in conjunction with instruments to measure voltage and current levels accurately. Potential transformers (PTs) are commonly used for voltage measurement.

-

Power Quality Improvement:

- Certain types of transformers, such as distribution transformers with tap changers, are used to regulate voltage and improve power quality by maintaining a stable voltage level.

-

Energy Efficiency:

- Transformers are designed to be highly efficient, minimizing energy losses during the voltage transformation process. This contributes to the overall efficiency of electrical power systems.

-

Frequency Transformation:

- While less common, transformers can also be used to change the frequency of an AC power system.

How do transformers work?

Transformers operate based on the principles of electromagnetic induction, as described by Faraday's law. The basic operation of a transformer involves the transfer of electrical energy between two or more coils through a changing magnetic field. Here's a step-by-step explanation of how transformers work:

-

Alternating Current (AC) Input:

- Transformers are designed to work with alternating current (AC) input. The primary coil (winding) is connected to an AC power source, creating an alternating magnetic field around it.

-

Magnetic Field Generation:

- When AC flows through the primary coil, it generates a changing magnetic field around the coil. The magnetic field expands and collapses with each cycle of the alternating current.

-

Induction of Voltage in Secondary Coil:

- The changing magnetic field induces a voltage in the secondary coil (winding) through electromagnetic induction. The induced voltage is proportional to the rate of change of the magnetic field and the number of turns in the secondary coil.

-

Voltage Transformation:

- The turns ratio of the primary and secondary coils determines the voltage transformation. If the secondary coil has more turns than the primary coil, it is a step-up transformer, increasing the voltage. Conversely, if the secondary coil has fewer turns, it is a step-down transformer, decreasing the voltage.

-

Transfer of Electrical Energy:

- The induced voltage in the secondary coil allows electrical energy to be transferred from the primary coil to the secondary coil. This transfer of energy occurs without a direct electrical connection between the two coils.

-

Magnetic Core Enhancement:

- The coils are often wound around a magnetic core made of ferromagnetic material, such as laminated iron. The core enhances the magnetic coupling between the coils, improving the efficiency of energy transfer.

-

AC Output:

- The voltage induced in the secondary coil becomes the output voltage of the transformer. This output voltage can be used for various applications, such as power distribution, electrical appliances, or industrial machinery.

Types of transformers

Transformers come in various types, each designed for specific applications and functions. Here are some common types of transformers:

-

Power Transformers:

- Used in power generation plants, these transformers step up the voltage of electricity generated for efficient long-distance transmission. They are also used to step down voltage for local distribution.

-

Distribution Transformers:

- Found on utility poles or in substations, distribution transformers further step down voltage for use in residential, commercial, and industrial areas. They are essential for local power distribution.

-

Instrument Transformers:

- These transformers are used in conjunction with measuring instruments to provide accurate voltage and current measurements. Current transformers (CTs) measure current, while potential transformers (PTs) measure voltage.

-

Auto Transformers:

- Auto transformers have a single winding with two or more taps, allowing them to function as both step-up and step-down transformers. They are often used in voltage regulation applications.

-

Isolation Transformers:

- Designed to provide electrical isolation between the primary and secondary circuits, isolation transformers enhance safety by preventing direct contact with the primary voltage.

-

Rectifier Transformers:

- Used in rectifier circuits to convert alternating current (AC) to direct current (DC) by supplying the required pulsating DC voltage to the rectifiers.

-

Current Transformers (CTs):

- Specialized transformers designed to measure high currents accurately. They are commonly used in power system protection and metering applications.

-

Potential Transformers (PTs):

- Also known as voltage transformers, PTs are used to measure high voltages accurately. They step down high voltages to levels suitable for metering and protection devices.

-

Audio Transformers:

- Used in audio equipment to match impedance levels between different audio devices and ensure efficient transfer of audio signals.

-

Ferroresonant Transformers:

- Also known as constant voltage transformers (CVTs), these transformers are designed to provide a relatively constant output voltage despite variations in input voltage.

-

Pulse Transformers:

- Specifically designed for applications involving pulse signals, such as in telecommunications and electronic circuits.

-

Resonant Transformers:

- Used in resonant circuits and applications where resonance effects are desired. They are often employed in radio-frequency (RF) circuits.

-

Oil-Immersed Transformers:

- Transformers immersed in oil for cooling and insulation purposes. The oil provides effective cooling and helps insulate the windings.

-

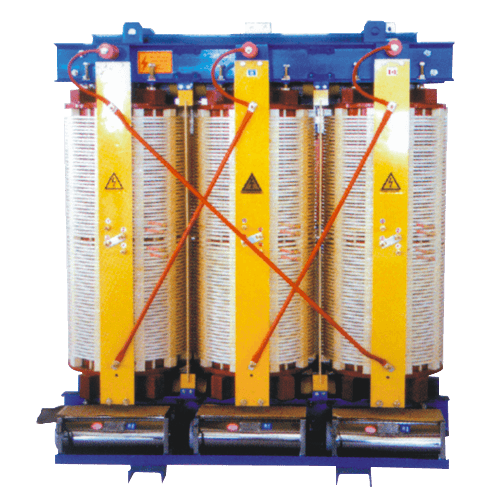

Dry-Type Transformers:

- Transformers that use air or other gases for cooling instead of oil. They are often preferred in indoor applications where the use of oil is impractical.

Where can I find a transformer manufacturer and is it cheap?

ztelecgroup is a manufacturer that specializes in manufacturing transformers, and its manufacturing standards can meet the standards of various countries. Friends in need can consult and purchase

leave a message

If you are interested in our products, please feel free to contact us or send email to us. Email address:sales@ztelecgroup.com

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer

- product categorys

- ELECTRICAL INSULATION BOARD MATERIALS

- ELECTRICAL INSULATION MATERIALS

- POWER TRANSFORMER

- ENAMELED WIRE

- SWITCHGEAR

- FOLLOW US

- customer case

- fetured products

EPGC308 Epoxy Fiberglass Sheet

SMC Sheets

- tags

- composite insulation materialsNHN vs. AHA InsulationNHN and AHA Insulation PaperNMN and AMA Insulation PaperNMN Insulation PaperEPGC308 Epoxy SheetEPGC203 Insulation Epoxy SheetsEpoxy FR4 yellow boardEpoxy FR4 Yellow LaminateEpoxy FR4 Yellow Transformer Insulation MaterialsYellow Epoxy Resin FR4electrical laminated woodinsulation paperHalogen Free G10 Epoxy SheetKraft Paper Insulation Paperdmd insulation paperDMD Epoxy Prepreg MaterialWhite DMD and Red Prepreg DMDlow-voltage dry-type distribution transformerpower transformer for high-rise buildingsEpoxy Pultruded RodsFR4 Material Densitytransformer production processBlack Core FR4 Materialpower transformer types