Analysis of the advantages and disadvantages of 3240 and FR-4 epoxy sheets

In the electronic and industrial fields, the selection of insulating materials plays a key role in product performance. As a common insulating material, epoxy sheets are widely used in the manufacture of various equipment due to their excellent electrical and mechanical properties. Among them, FR4 epoxy sheets and 3240 epoxy sheets are the two most common types in the industry. They each have unique performance advantages and are suitable for different application scenarios. Next, we will deeply analyze the advantages and disadvantages of these two epoxy sheets to provide engineers and designers with a comprehensive reference for material selection.

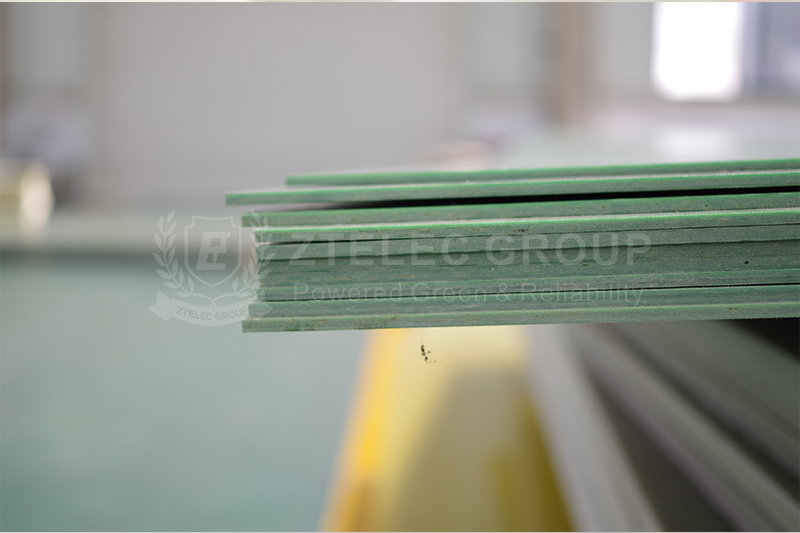

1. FR4 epoxy sheet

FR4 epoxy sheet is a kind of glass cloth-based epoxy resin board and the main material for printed circuit board (PCB) manufacturing. It is popular because it has achieved a good balance between electrical insulation performance and mechanical processing performance.

In terms of electrical performance, the insulation performance of FR4 sheet is moderate. Therefore, it can meet the application requirements of most conventional electronic circuits. Whether it is consumer electronics such as mobile phones and computer motherboards, or circuit boards in industrial control equipment, FR4 epoxy sheets can stably play the role of insulation and support circuit components.

Moreover, FR4 sheets perform well in terms of mechanical processing performance. It can be accurately processed into a circuit board shape that meets the design requirements through common mechanical processing methods such as drilling, milling, and cutting. In addition, it is cost-effective. The relatively low price makes PCBs made of FR4 sheets highly competitive in the market. It is especially suitable for cost-sensitive mass production projects.

2. 3240 Epoxy Sheet

3240 epoxy sheet belongs to the category of high-performance epoxy sheet. Compared with FR4 sheet, it has been optimized and improved in multiple key performance indicators.

In terms of electrical properties, 3240 epoxy sheet has lower dielectric constant and loss factor. This feature makes it stand out in high-frequency circuit applications. In fields such as 5G communication equipment and radar systems that have extremely high requirements for signal transmission, the use of 3240 epoxy sheet can effectively reduce the delay and energy loss in the signal transmission process, thereby ensuring the integrity and accuracy of the signal.

Heat resistance is also a major advantage of 3240 epoxy sheet. It can maintain stable physical and electrical properties in a relatively higher temperature environment. Therefore, it is more suitable for high-temperature working environments with high heat generation such as aerospace and automotive electronics.

In addition, 3240 epoxy sheet is also superior in mechanical properties. It has better wear resistance and impact resistance, and can withstand more complex mechanical stress. Even in harsh use environments, it can maintain good structural integrity.

3. Application scenarios and selection suggestions

In actual projects, engineers need to weigh the choice of FR4 epoxy sheet or 3240 epoxy sheet according to specific application requirements.

If the project focuses on conventional electronic circuit design, the electrical performance requirements are at the industry average level, and the cost needs to be strictly controlled, then FR4 epoxy sheet is undoubtedly a more suitable choice. Because its manufacturing process is mature, the market is widely used, and procurement and processing are more convenient.

For high-end application scenarios that pursue high-frequency performance and need to operate stably under high temperature environments, 3240 epoxy sheet is the best choice. Although its price is relatively high, its excellent performance can fully reflect its value in areas with demanding product performance and reliability.

FR4 epoxy sheet and 3240 epoxy sheet have their own advantages and play an important role in different application fields. A deep understanding of the characteristics and differences of these two epoxy sheets will help engineers and designers make scientific and reasonable material choices based on the specific needs of the project, which ensures product performance and improves market competitiveness.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele