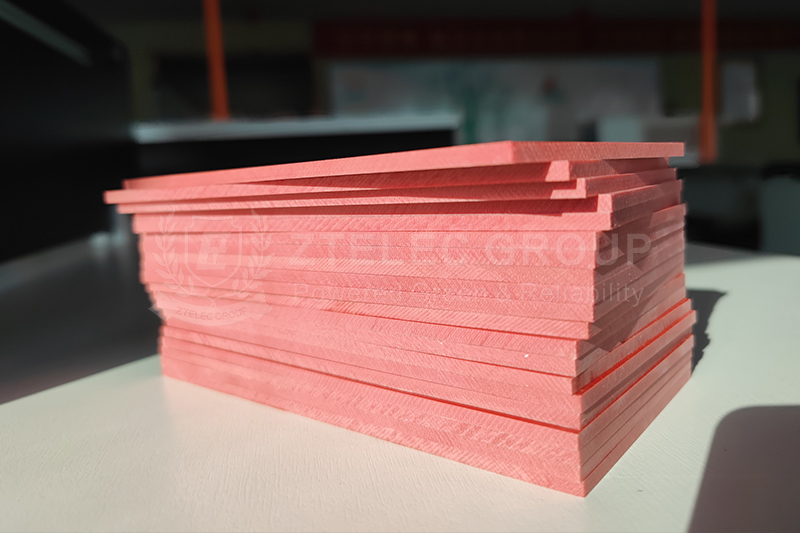

Electrical Grade Bakelite Plate – Ideal for Switchgear and Transformer Insulation

1.Basic Characteristics and Manufacturing Process of Bakelite

Bakelite, also known as phenolic laminated paperboard, is a high-grade insulating material made of high-quality bleached wood pulp paper or cotton linter paper as reinforcement material, impregnated with fully synthetic phenolic resin, and hot-pressed under high temperature and high pressure conditions. Its unique production process gives the material a series of excellent physical and electrical properties, making it outstanding in the field of power equipment.

The production process of Bakelite has strict quality control. First, the cellulose substrate is carefully selected, then it is impregnated with modified phenolic resin, and then it undergoes a precisely controlled baking and hot pressing process to finally form a board with a dense structure and stable performance. According to different performance requirements, Bakelite has derived a variety of models, each model has slight differences in indicators such as bending strength, bonding strength and insulation resistance, so as to adapt to the insulation requirements of various electrical equipment.

Bakelite has a unique property that it cannot be reshaped after heating and forming. This feature ensures the dimensional stability and long-term reliability of the material in the use environment. At the same time, it also has the advantages of being non-absorbent, non-conductive, high temperature resistant and high strength. These characteristics together establish its important position in the field of electrical insulation.

2. Key Applications of Bakelite in Switchgear

As the core component of control and protection in the power system, the insulation performance of switchgear is directly related to the safe operation of the entire system. With its excellent insulation performance and mechanical strength, bakelite has become the preferred material for insulating partitions, gaskets and supports in switchgear.

In high-voltage switchgear, bakelite is often used as phase-to-phase isolation board and grounding switch insulation support, which can effectively prevent phase-to-phase short circuit and grounding fault. In medium-voltage switchgear such as ring main unit, the stable performance of bakelite provides reliable insulation protection for the equipment.

The operating mechanism insulation parts of the switchgear are also mostly made of bakelite. This material can withstand the stress generated by frequent mechanical operation and is not prone to cracks or deformation. At the same time, its good wear resistance and creep resistance ensure that precise mechanical matching can be maintained after long-term use, reducing equipment failures caused by wear of insulating parts.

With the development of modern switchgear towards miniaturization and high-density layout, higher requirements are placed on insulation materials.

The easy processing characteristics of bakelite allow it to be precisely cut into complex shapes by CNC equipment to meet the design requirements of compact switchgear. Whether it is a UHF sensor mounting plate or an insulating bracket for a three-in-one partial discharge monitoring device, bakelite can ensure precise dimensions and stable performance. In addition, bakelite also exhibits excellent arc resistance in switchgear. When partial discharge or arc fault occurs inside the equipment, it will not form a conductive carbonization channel, effectively reducing the risk of fault expansion.

3. The Outstanding Performance of Bakelite in Transformer Insulation

As the core equipment of the power system, the reliability of the insulation system of the transformer directly affects the stable operation of the power grid. With its unique material properties, electrical-grade bakelite plays an indispensable role in the field of transformer insulation, especially in key components such as insulating gaskets, partitions and supporting structures.

In oil-immersed transformers, bakelite is often used as an insulating partition between high and low voltage windings. Its excellent oil resistance enables it to be used in transformer oil for a long time, and its stable dielectric properties ensure reliable electrical isolation between windings, which can effectively prevent breakdown between windings.

The core clamps and pressure plates of large power transformers are often made of high-density bakelite. The mechanical strength of bakelite fully meets the mechanical requirements of large transformer structures.

Dry-type transformer interlayer insulation and end insulation also use bakelite in large quantities. Its good thermal stability can withstand the temperature rise during transformer operation, and its low thermal expansion coefficient ensures the dimensional stability of the insulation structure during temperature changes, which is crucial to maintaining the tightness of transformer windings and preventing insulation loosening.

In the application of insulation components of transformer tap changers, bakelite also performs well. When the tap changer adjusts the voltage ratio, an arc will be generated. The arc resistance and anti-tracking performance of the bakelite ensure the reliability of the switch operation. Its low moisture absorption avoids the degradation of insulation performance due to humidity changes, and its application advantages in outdoor transformers and humid environments are significant.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele