How DDP Insulation Enhances the Performance and Lifespan of Oil-Immersed Transformers

In modern power systems, oil-immersed transformers serve as a core component, and their performance and lifespan directly impact the reliability and cost-effectiveness of the grid. DDP (Diamond Dotted Paper), through innovations in materials and optimized manufacturing processes, has achieved major breakthroughs in key areas such as insulation performance, mechanical strength, and heat dissipation efficiency. It has become a core technology for enhancing the overall performance of transformers. The following sections provide an in-depth analysis of its technical advantages from multiple dimensions.

1. Structural Innovation

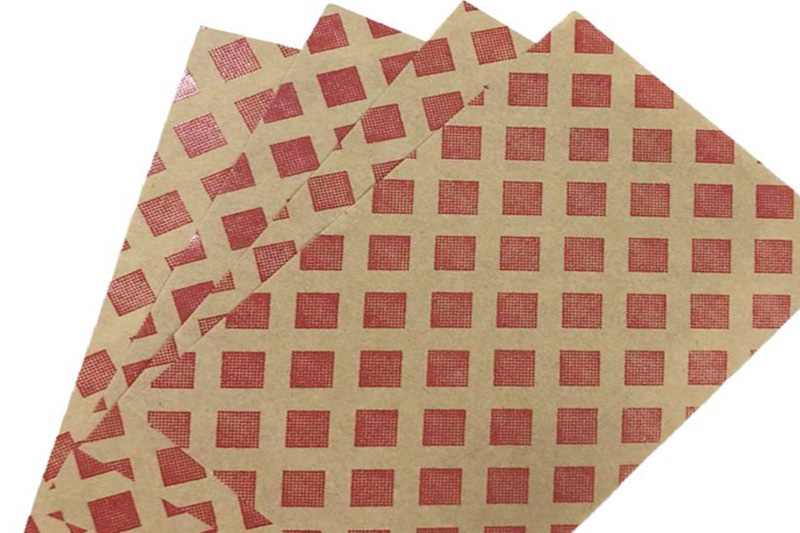

DDP insulation material employs a specialized modified epoxy resin applied in a diamond-patterned dot coating on the insulation paper, precisely forming resin dots on its surface. This unique design plays a crucial role during the drying process of transformer coils: under specific temperature conditions, the resin layer melts and then cures, creating a firm and reliable mechanical bonding between coil layers.

Significantly Enhances Short-Circuit Resistance:

Once cured, the resin layer exhibits high adhesive strength, effectively withstanding the intense electromagnetic forces generated during short circuits. This fundamentally prevents insulation failure caused by interlayer displacement, ensuring the safe operation of transformers under extreme conditions.

Ensures Long-Term Operational Stability:

The diamond-shaped structure is cleverly designed to allow transformer oil to freely penetrate, ensuring thorough impregnation of the insulation system. At the same time, it forms efficient channels for gas release, preventing localized partial discharges caused by trapped gases. This delays the aging of insulation and extends the service life of the transformer.

2. Electrical Performance Optimization

The dotted resin coating design of DDP insulation material brings significant improvements to the electrical performance of oil-immersed transformers:

Increased Partial Discharge Inception Voltage:

By precisely optimizing the diamond pattern spacing, the uniformity of the electric field distribution is greatly enhanced. This significantly reduces the risk of partial discharge, improving the operational safety of the transformer under high-voltage conditions.

Reduced Dielectric Loss:

The composite structure formed by the epoxy resin coating and insulation paper greatly lowers the dielectric loss factor, minimizing unnecessary energy dissipation during power transmission and improving the overall energy efficiency of the transformer.

Enhanced Corona Resistance:

In high-voltage electric field environments, DDP insulation material effectively delays the onset of corona discharge, slowing down the insulation aging process and further improving the electrical insulation performance and service life of the transformer.

3. Thermal Management Optimization

The diamond pattern structure of DDP insulation material has a profound and positive impact on the thermal management of transformers:

Optimized Oil Flow Channels:

The gaps formed by the dotted resin coating effectively reduce the flow resistance of transformer oil, promote efficient oil circulation, and significantly enhance heat dissipation efficiency. This ensures effective thermal exchange during operation and helps the transformer maintain a stable operating temperature.

Improved Temperature Rise Uniformity:

By precisely controlling the size and distribution density of the diamond pattern, DDP helps reduce hot spot temperature rise in the windings, avoiding localized overheating. This leads to a more uniform temperature distribution and improves the transformer's operational stability.

Enhanced Overload Capability:

Under overload conditions, transformers using DDP insulation material can operate continuously and stably for extended periods without insulation damage. This greatly enhances the transformer's ability to cope with sudden power demand surges.

With innovative breakthroughs in structural design, electrical performance, and thermal management, DDP technology has redefined the performance standards of oil-immersed transformers. Amid the accelerating global energy transition and rising power demands, this technology not only provides a reliable foundation for the safe and stable operation of power grids but also drives the power industry toward greater efficiency and intelligence. As the technology continues to evolve and see wider adoption, DDP is poised to unleash even greater potential in the future power sector, injecting strong momentum into the development of next-generation power systems.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer