Application of DDP in Oil-Immersed Transformers: Technical Parameters, Interlayer Insulation, and Reliability Analysis

The stable operation of electrical equipment is the cornerstone of modern power supply security. As a critical hub in power transmission, the performance of internal insulation materials in oil-immersed transformers is of paramount importance. DDP insulation material, with its unique advantages, plays an irreplaceable role in transformer applications. Below, we delve into the application of DDP in oil-immersed transformers, covering technical parameters, interlayer insulation characteristics, and reliability enhancement analysis.

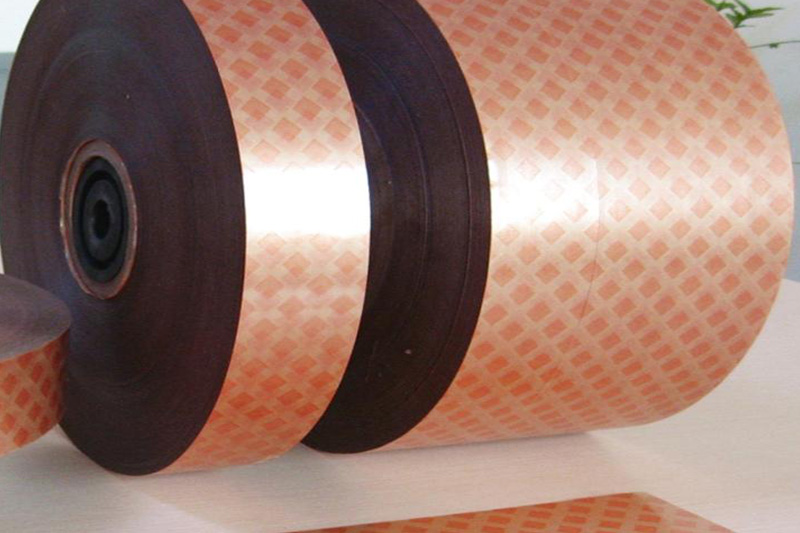

Technical Parameters of DDP Insulation Material

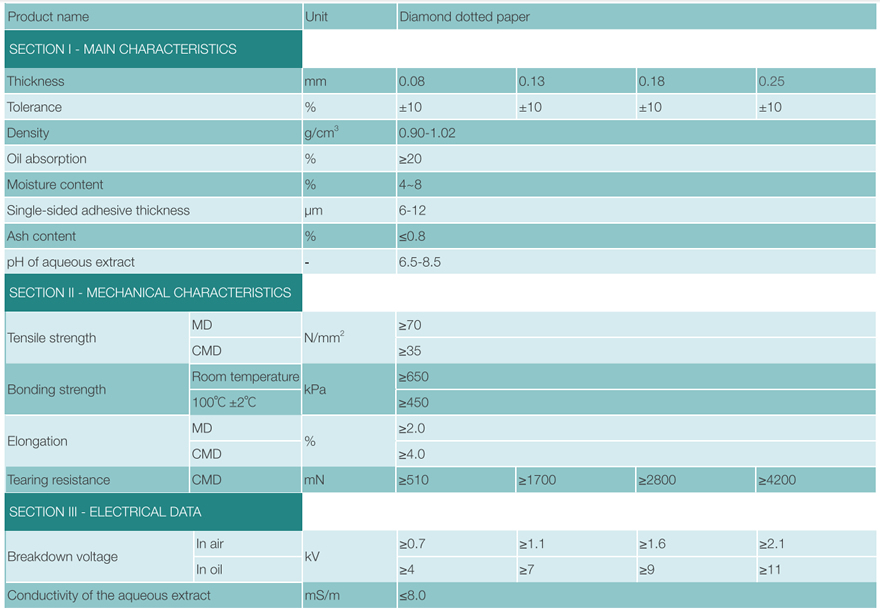

1.Thickness: The thickness of DDP diamond-pattern adhesive paper typically ranges from 0.08mm to 0.45mm, depending on application requirements and manufacturing processes. Common thicknesses include 0.13mm, 0.18mm, and 0.25mm.

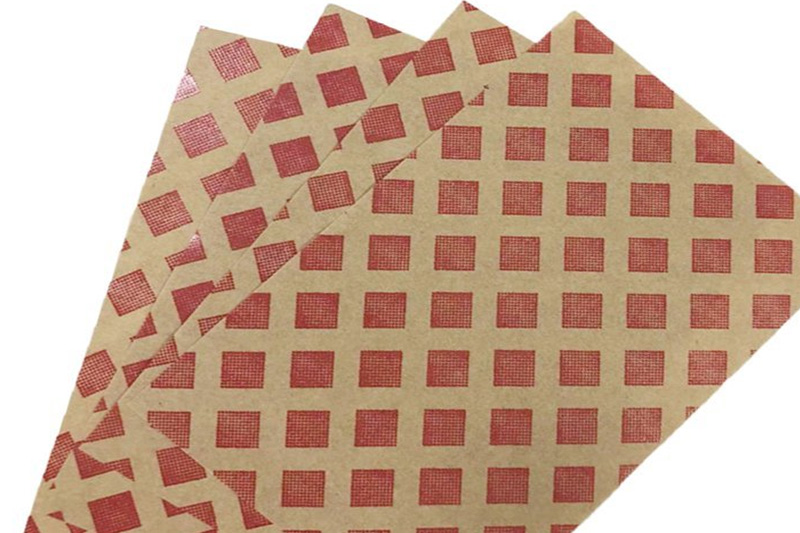

2.Color: DDP diamond-pattern adhesive paper is usually natural wood pulp color (light yellow or light brown). Some products may feature special adhesive colors, such as rose red or light red, to enhance product recognition and aesthetics.

3.Dimensions: The dimensions of DDP diamond-pattern adhesive paper are generally flexible and can be customized according to customer needs. The standard width is typically 1000mm ± 20mm.

4.Insulation Class: DDP is insulation class A according to IEC 641.

5.Application: DDP insulation material is primarily used for turn-to-turn and interlayer insulation in the windings of oil-immersed power transformers.

6.Adhesive Dot Distribution: The adhesive dots on DDP diamond-pattern adhesive paper are arranged in a diamond grid pattern, which not only improves insulation performance but also enhances the material’s mechanical strength.

In addition to the above parameters, DDP has other specifications. For details, please refer to the table below.

Application of DDP Insulation Material in Interlayer Insulation

In oil-immersed transformer systems, interlayer insulation serves as the critical barrier against inter-turn short circuits, with its performance directly determining the transformer's safety and stability. Due to its exceptional insulation properties and mechanical strength, DDP insulation material has become the optimal choice for interlayer insulation applications.

1.Innovative Dot-Coating Design:

DDP insulation material features a unique resin dot-coating design that not only ensures complete impregnation of insulating oil into the material but also effectively expels trapped gases. This design effectively prevents corona discharge and partial discharge phenomena, providing solid reliability for the insulation structure.

2.Enhanced Interlayer Insulation Performance:

With its high breakdown voltage and excellent thermal class, DDP insulation material significantly improves the interlayer insulation strength of transformer windings, greatly reducing the risk of interlayer short circuits and strengthening the foundation for stable transformer operation.

3.Addressing Complex Operational Challenges:

During transformer operation, windings are continuously subjected to combined effects of thermal stress, mechanical stress, and electromagnetic forces. With its high bonding strength and superior mechanical properties, DDP insulation material can reliably maintain interlayer insulation stability under various complex operating conditions, ensuring dependable transformer performance.

Enhancement of Transformer Reliability by DDP Insulation Material

The application of DDP insulation material in oil-immersed transformers significantly improves equipment reliability across multiple dimensions, with specific manifestations as follows:

1.Reduction of Failure Probability:

With its outstanding insulation performance and mechanical strength, DDP insulation material effectively prevents transformer failures caused by insulation breakdown, significantly enhancing operational reliability and reducing unexpected downtime.

2.Extension of Equipment Service Life:

This benefit stems from its high thermal endurance rating. DDP insulation material maintains stable performance during long-term operation, greatly minimizing the risk of insulation failure due to thermal aging, thereby effectively prolonging transformer service life and enhancing whole-lifecycle value.

3.Reduction of Maintenance and Operational Costs:

The superior performance of DDP insulation material substantially decreases transformer failure frequency and maintenance requirements. This effectively lowers maintenance costs while reducing potential economic losses caused by equipment failures, delivering significant economic benefits to enterprises.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer